D-sub, High density connectors technical characteristics – Northern Connectors Harting D-sub Connectors, Housings & Accessories User Manual

Page 37

05

36

D-Sub

D-Sub

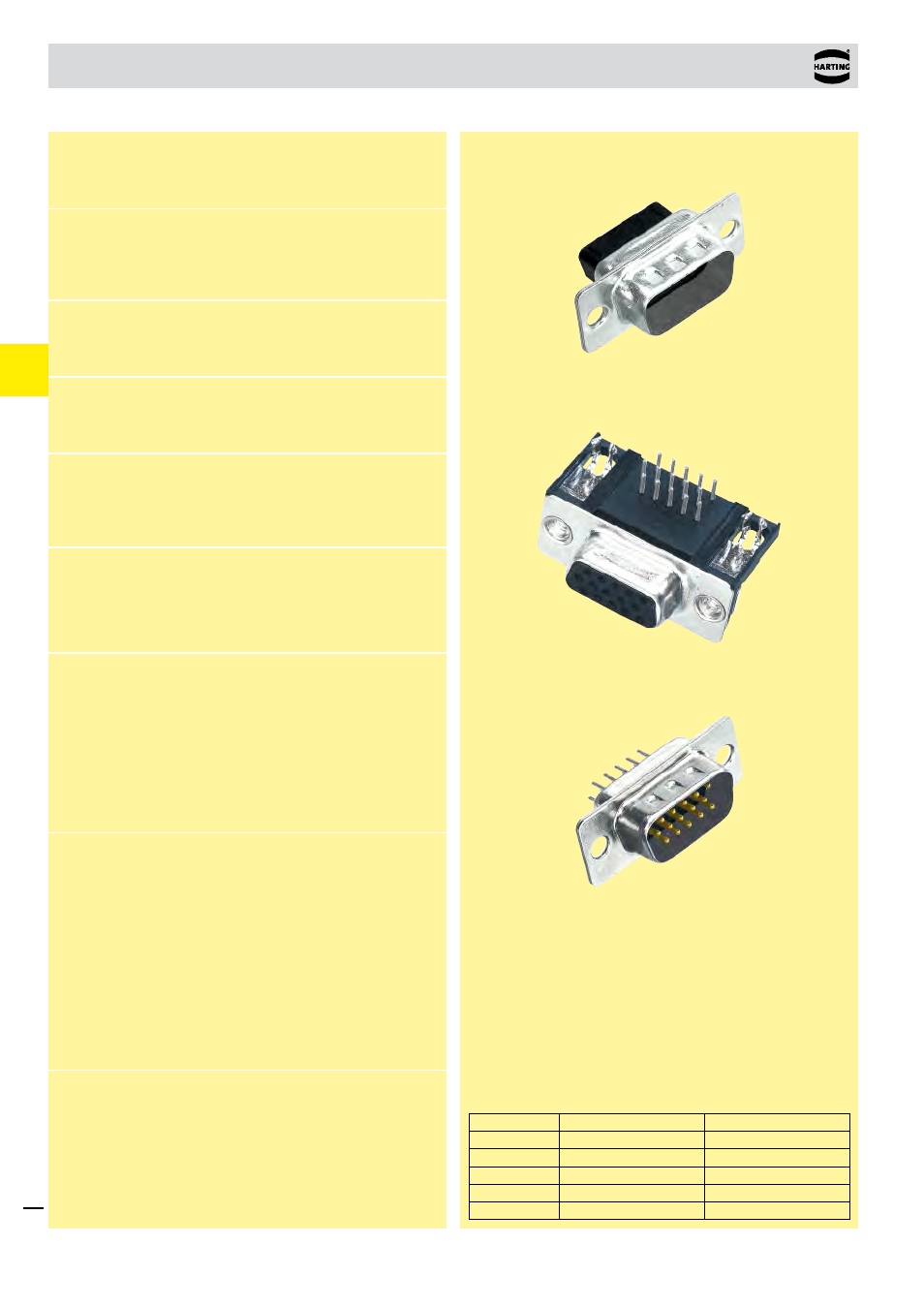

high density connectors

Technical characteristics

1)

Performance level 3, 50 mating cycles, no gas test

S4, plating = 0.76 µm (30 µinch) Au or PdNi equivalent

Shell size

D-Sub standard

D-Sub high density

1

9

15

2

15

26

3

25

44

4

37

62

5

50

78

Number of contacts in the D-Sub standard/D-Sub high density

range related to the shell size.

Number of contacts

15, 26, 44, 62, 78

Working current

Stamped contacts

2 A max.

Test voltage U

r.m.s.

1 kV

Clearance and creepage

≥ 1.0 mm

Contact resistance

< 20 mΩ

< 25 mΩ (for right angled versions)

Insulation resistance

≥ 5 x 10

9

Ω

Temperature range

-40

O

C … + 85

O

C

The higher temperature limit includes the local ambient and

heating effect of the contacts under load

Terminations

a) Solder pins Ø 0.65 mm for

P.C.B. holes Ø 1.0 mm

b) Crimp contacts

AWG 26 - 24

0.14 - 0.22 mm²

max. insulation Ø 1.38 mm

c) Solder cups

AWG 24

Materials

Mouldings and hoods

Thermoplastic resin, glass-

fibre filled (PBTP),

UL 94-V0

Contacts

Copper alloy

Contact surface

Contact zone

selectively plated according

to performance level

1)

Metal shell

Plated steel

Mating force

15 way ≤ 46 N

26 way ≤ 77 N

44 way ≤ 127 N

62 way ≤ 177 N

78 way ≤ 222 N