D-sub, Cable connectors technical characteristics – Northern Connectors Harting D-sub Connectors, Housings & Accessories User Manual

Page 26

05

25

D-Sub

M

F

M

F

M

F

M

F

M

F

D-Sub

Cable connectors

Technical characteristics

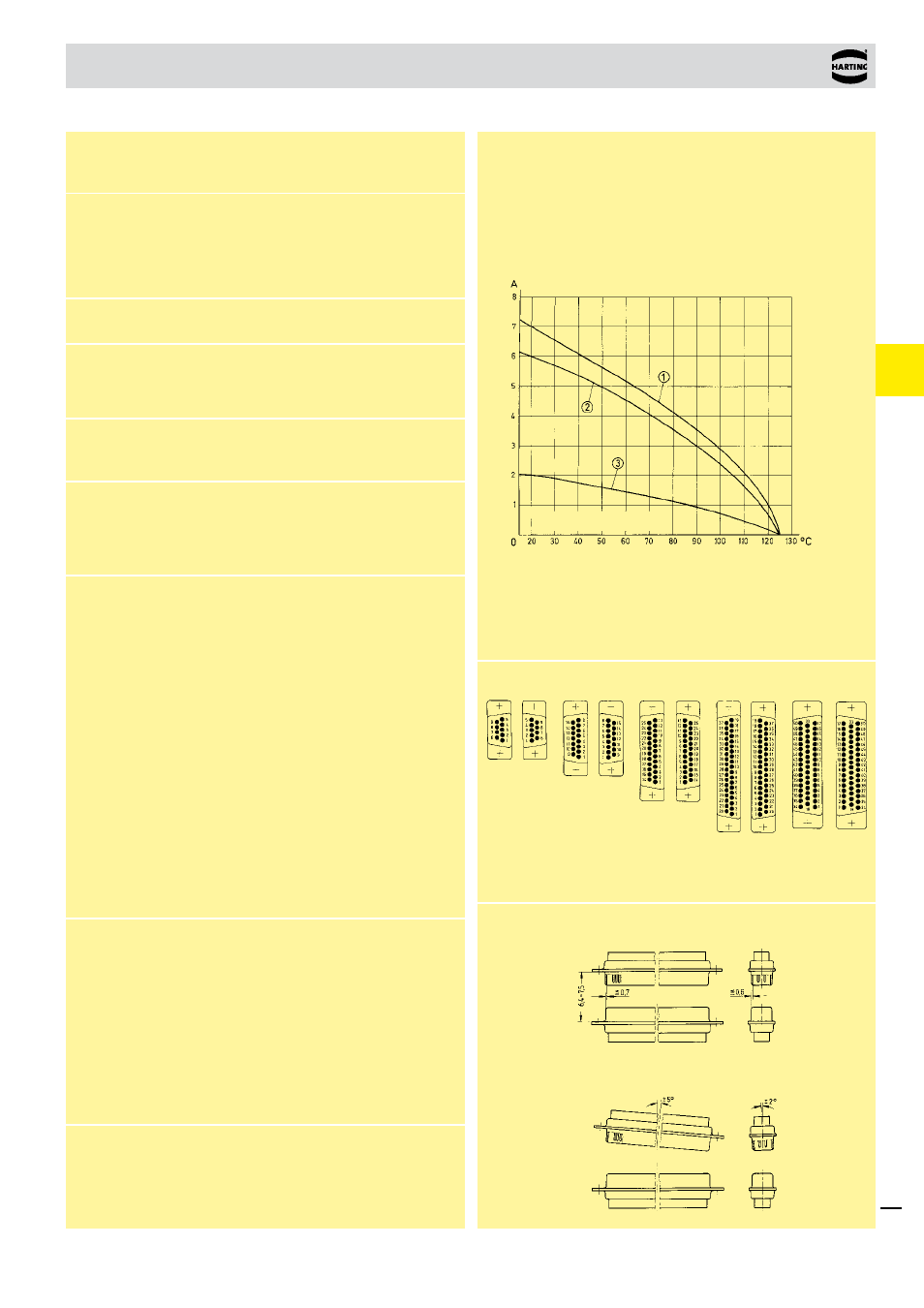

Current carrying capacity

The current carrying capacity is limited by maximum temperature

of materials for inserts and contacts including terminals. The cur-

rent capacity-curve is valid for continuous, not interrupted current-

loaded contacts of connectors when simultaneous power on all

contacts is given, without exceeding the maximum temperature.

Control and test procedures according to DIN IEC 60 512.

Contact arrangement

View from termination side

Mating conditions

as per DIN 41 652

M = Male connector

F = Female connector

W

or

king current

Ambient temperature

Wire gauge: 0.5 mm

2

Example: 25 way connector

➀

Turned contacts

➁

Stamped contacts

➂

Insulation displacement contacts

1)

Performance level 3, 50 mating cycles, no gas test

Performance level 2 as per CECC 75 301-802, 250 mating cycles, 4 days 4 mixed gas test – IEC 60 512

Performance level 1 as per CECC 75 301-802, 500 mating cycles, 10 days 4 mixed gas test – IEC 60 512

37 way

50 way

9 way

15 way

25 way

Number of contacts

9, 15, 25, 37, 50

UL recognized

Working current

see current carrying capacity chart

Turned contacts

7.5 A max.

Stamped contacts

6.5 A max.

Insulation displacement

2

.0

A max.

Test voltage U

r.m.s.

1 kV

Clearance and creepage

≥ 1.0 mm

≥ 0.7 mm (insulation

displacement)

Contact resistance

≤ 10 mΩ

Insulation resistance

≥ 10

10

Ω

Temperature range

turned version

-55

O

C … + 125

O

C

stamped solder

bucket version

-40

O

C … + 85

O

C

Terminations

a) Solder buckets

AWG 20

b) Stamped crimp contacts

AWG 28-24

0.09-0.25 mm²

max. insulation Ø 1.02 mm

AWG 24-20

0.25-0.56 mm²

max. insulation Ø 1.52 mm

c) Turned crimp contacts

AWG 22-18

0.33-0.82 mm²

AWG 24-20

0.25-0.52 mm²

AWG 26-22

0.13-0.33 mm²

AWG 28-24

0.09-0.25 mm²

max. insulation Ø 2.15 mm

d) Insulation displacement

AWG 28/7 and AWG 26/7

Materials

Mouldings and hoods

Thermoplastic resin, glass-

fibre filled (PBTP),

UL 94-V0

Contacts

Copper alloy

Contact surface

Contact zone

selectively plated according

to performance level

1)

Metal shell

Plated steel

Mating force

9 way ≤ 30 N

15 way ≤ 50 N

25 way ≤ 83 N

37 way ≤ 123 N

50 way ≤ 167 N