D-sub, Mounting details – angled solder pins – Northern Connectors Harting D-sub Connectors, Housings & Accessories User Manual

Page 12

05

11

D-Sub

DIN 41 612

DIN 41 612

DIN 41 612

DIN 41 612

D-Sub

PCB

PCB

PCB

PCB

Low-Profile Versions

Standard

Versions US

Footprint

Advantages

Mounting height

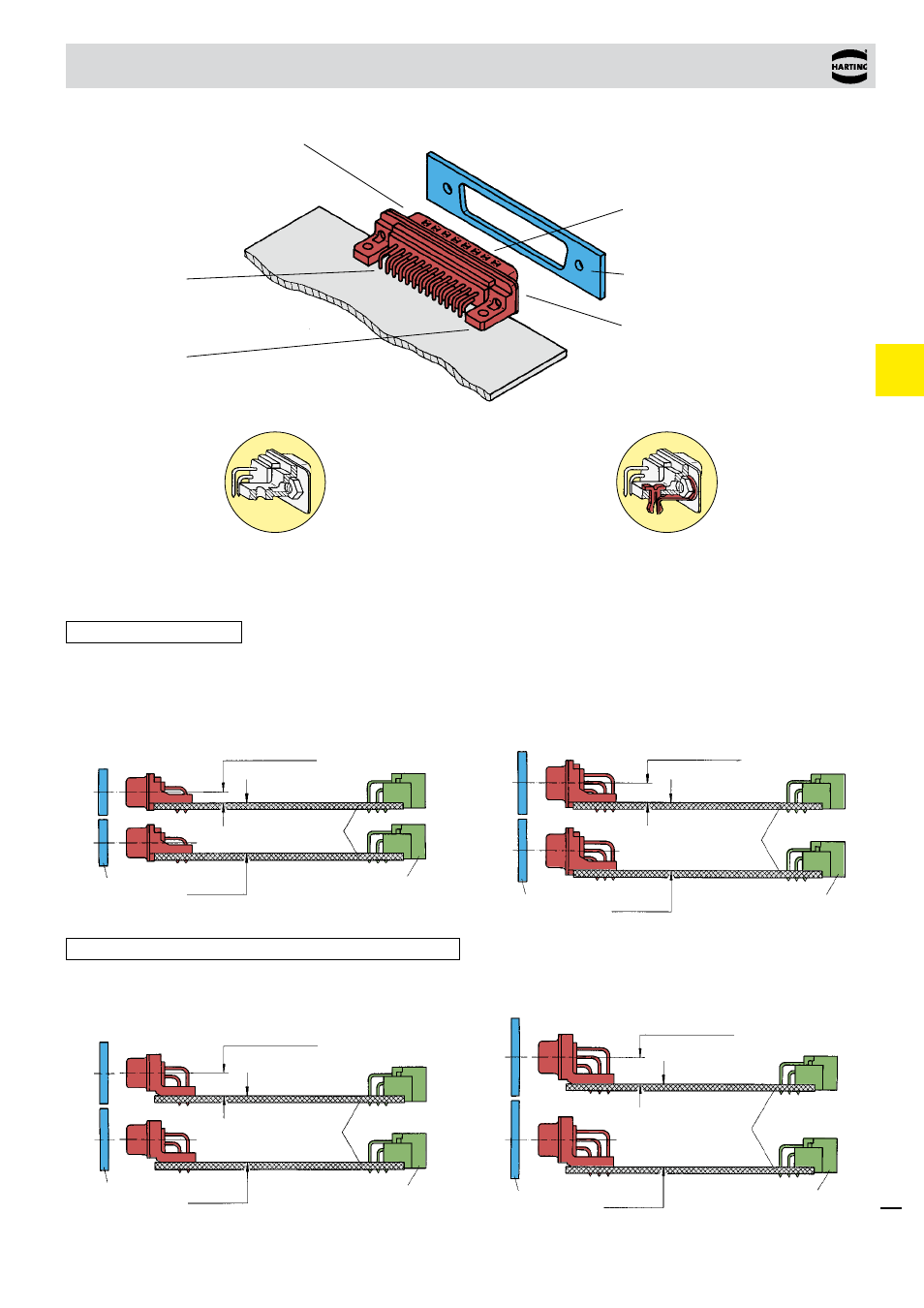

All-round protective metal shell

●

Polarisation

●

Contact protection

●

Plated shell

●

Male connector with

dimples

Plated terminations

for increased

solderability

Grounding contact

riveted to

metal shell

Integrated plastic mounting bracket

Different metal threads possible

in flange area

●

M3

●

4-40 UNC

●

fitted female screw locks

4-40 UNC

●

max. torque ≤ 0.8 Nm

Panel

Contact surface finish to different

performance levels

Mounting bracket

Mounting bracket

with snap-in-clips and grounding pin

The reduced mounting height of these connectors

allow them to be used on the same PCB as DIN 41 612

types with no loss of packaging density when card

frames to DIN 41 494 are used.

9-37 way connectors with 3.6 mm mounting height can be

fitted to front panels of 3 TE (15.24 mm) width.

Mounting height 3.6 mm

Panel

3 TE

3 x 5.08 mm = 15.24 mm

50 way connectors with 6.2 mm mounting height can be

fitted to front panels of 4 TE (20.32 mm) width.

Mounting height 6.2 mm

Panel

4 TE

4 x 5.08 mm = 20.32 mm

9-37 way connectors with 7.3 mm mounting height can be

fitted to front panels of 4 TE (20.32 mm) width.

Mounting height 7.3 mm

(6.3 US Footprint)

Panel

4 TE

4 x 5.08 mm = 20.32 mm

50 way connectors with 8.7 mm mounting height can be

fitted to front panels of 5 TE (25.4 mm) width.

Mounting height 8.7 mm

Panel

5 TE

5 x 5.08 mm = 25.4 mm

Mounting details – angled solder pins