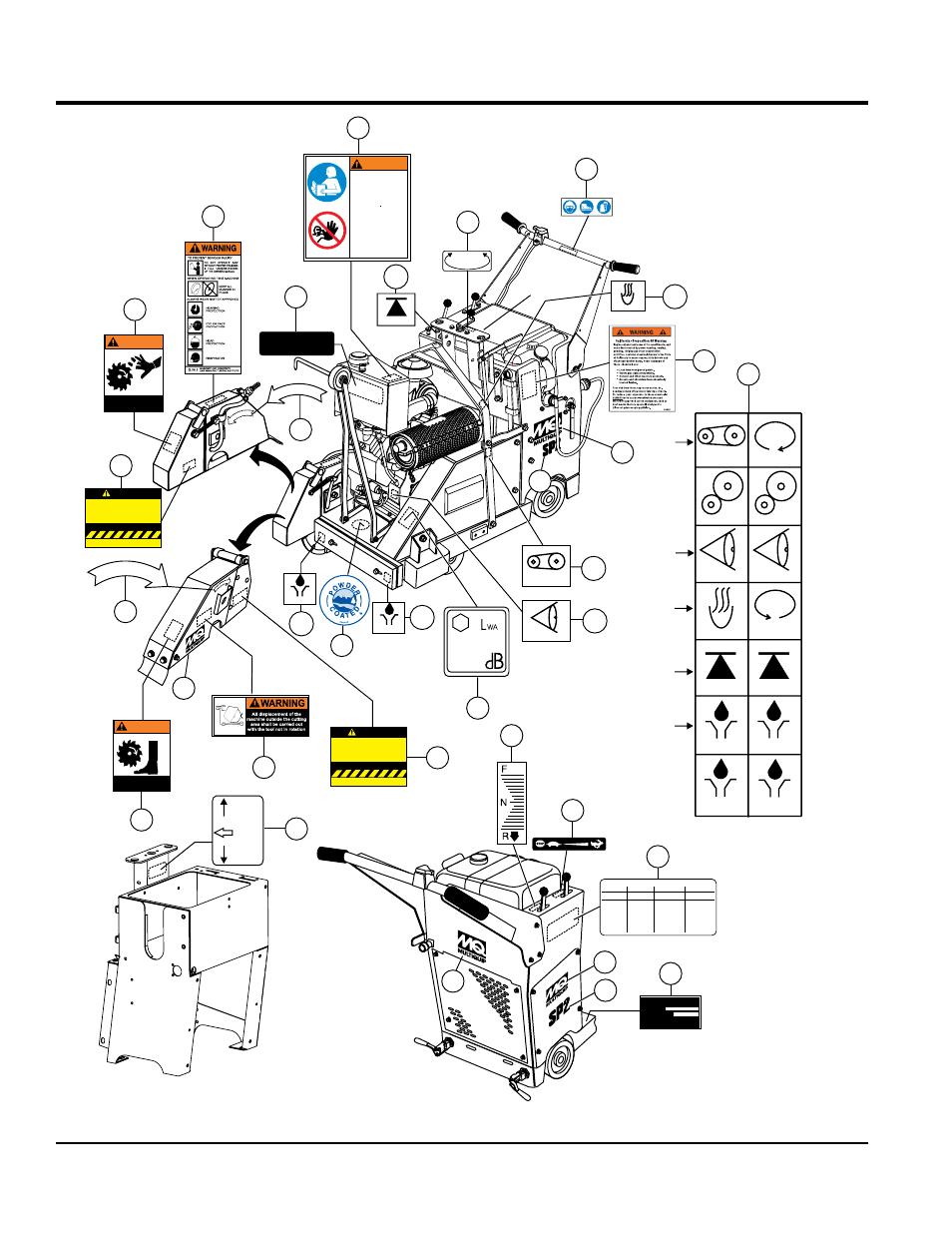

Nameplate and decals, Ce b d a – Multiquip SP2S20H User Manual

Page 8

page 8 — Sp2S20h paVeMeNT SaW • operaTioN aNd parTS MaNual — reV. #0 (02/17/12)

naMEplatE anD DEcals

RO

TATION

RO

TATION

KEEP HANDS

CLEAR

WARNING

10

BELT DRIVE

HOT

8

3

5

114

LUBRICATION

LUBRICATION

KEEP FEET

CLEAR

WARNING

CHECK

GEAR DRIVE

GEAR DRIVE

CHECK

HOT

BELT DRIVE CLOCKWISE

COUNTER

CLOCKWISE

LUBRICATION

LUBRICATION

LIFTING POINT

LIFTING POINT

LUBRICATION

LUBRICATION

DECAL SHEET

INTL STDS ISO

P/N 11246

C

E

B

D

A

BLADE

LOWER

RAISE

35136

LIFTING POINT

UNLEADED GASOLINE

ONLY

MAX 10% ETHANOL

9

CAUTION

When Larger Blade and Guard

is Installed, Belt Drive MUST

Be Changed to Proper Size.

See Owners Manual.

S.M.I. MASONRY AND CONCRETE

SAW MANUFACTURER’S INSTITUTE

FAILURE TO COMPLY COULD RESULT

IN SERIOUS BODILY INJURY.

CAUTION

When Larger Blade and Guard

is Installed, Belt Drive MUST

Be Changed to Proper Size.

See Owners Manual.

S.M.I. MASONRY AND CONCRETE

SAW MANUFACTURER’S INSTITUTE

FAILURE TO COMPLY COULD RESULT

IN SERIOUS BODILY INJURY.

13

12

1

15

1

4

To avoid injury,

you MUST read

and understand

operator’s manual

before using this

machine.

Ask for training

as needed.

This machine to

be operated by

qualified

personnel only.

P/N 35137

WARNING

6

2

8

22

14

16

22E

22E

22A

22D

22C

P/N 36099

ENGAGE

DRIVE

LEVER

DISENGAGE

P/N 35135

MODEL

SERIAL NO.

8

RECOMMENDED MAINTENANCE

CHECK

LUBRICATE

CLEAN

DAILY:

OCCASIONALLY:

ENGINE OIL

SPINDLE BEARINGS

AIR CLEANER

(WHEN CUTTING DRY)

BELT TENSION

HYDROSTATIC

TRANSMISSION OIL

HYDRAULIC LIFT

SYSTEM RESERVOIR

(IF SO EQUIPPED)

ALL BEARINGS

SUBFRAME PIVOT

REAR AXLE

JACK SHAFT

HANDWHEEL

(IF SO EQUIPPED)

CLEVIS PINS

ROLLER CHAINS

FRONT WHEEL BEARINGS

LIFT MECHANISM

SCREW

(IF SO EQUIPPED)

FUEL STRAINERS

FILTERS

AIR CLEANER

WATER PUMP

INLET STRAINER

COMPLETE MACHINE

23596-001

19

8

17

18

9

20

7

21

11

22B

CHECK