Maintenance (old style clutch) – Multiquip HHXD5 User Manual

Page 31

HHXD5 RIDE-ON TROWEL • OPERATION MANUAL — REV. #3 (08/15/14) — PAGE 31

MAINTENANCE (OLD STYLE CLUTCH)

Spare Drive Belt Replacement

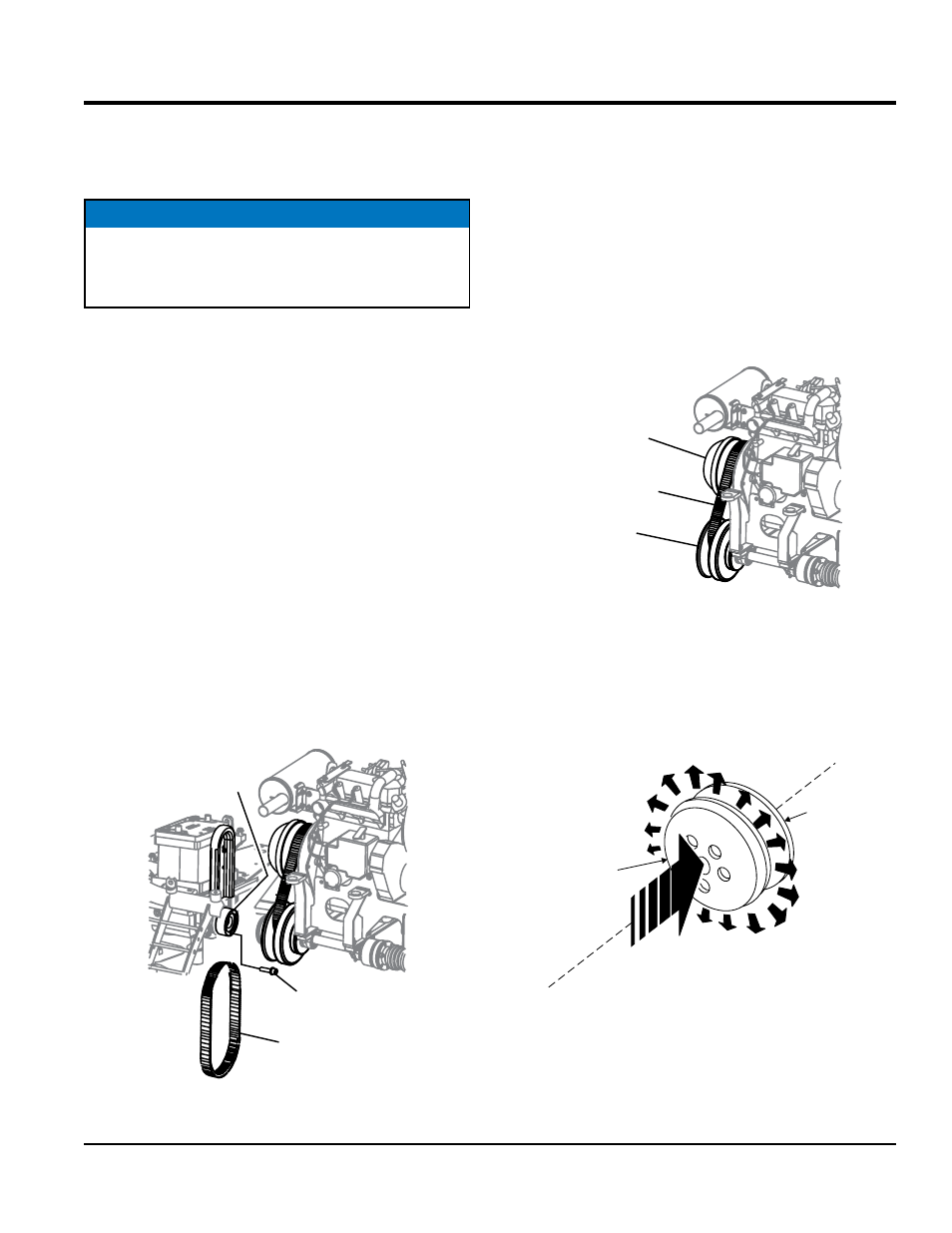

To replace a spare drive belt, be prepared to disconnect

the CV-joint from the left-side gearbox. See Figure 21.

1. Place the trowel on suitable supports and observe all

safety precautions.

2. Remove Left-side End Grate and open Left "Clamshell"

3. Remove the three screws that secure the CV-joint to

the left-side gearbox coupler.

4. Once the CV-joint has been separated from the left-side

gearbox, push the CV-joint inward so that a gap exists

between the gearbox and the CV-joint (Figure 21). Slide

the spare V-belt between the gearbox coupler and the

CV-joint. Avoid contaminating the replacement belt with

grease or oil when sliding it between the CV-Joint and

gearbox coupler.

5. Place the spare drive belt inside the drive belt carrier,

and secure the spare belt carrier to the inboard side

of the left gearbox.

6. Install the three screws that secure the CV-joint to the

left-side gearbox coupler.

Figure 21. Spare Drive Belt Replacement

NOTICE

It will be necessary to disconnect the CV-Joint from the

left-side gearbox coupler. This means the removal of the

three screws that secure the CV-Joint to the gearbox.

CV Joint Bolt

Left Side

Gearbox

New Spare

Drive Belt

The HHX is equipped with a "CVT" type clutch which

supplies torque to both the left and right gear boxes.

The function of the CVT, (Continuously Variable

Transmission), is to automatically deliver the correct amount

of torque required by the trowel under all load conditions.

This enables the trowel to deliver the necessary torque for

float pan applications and the high rotor speeds required

for burnishing concrete.

The Driven Pulley is a variable pitch pulley type, (Figure

22) connected by a drive belt.

Figure 22. CVT with Variable Pitch Drive

PulleyDrive Pulley

The Drive Pulley uses centrifugal force (Figure 23 and

Figure 24) to create a belt squeeze force transmitted at the

pulley faces. This condition functions as an automatic clutch.

Figure 23. Drive Pulley (Centrifugal Force)

Centrifugal force pushes the roller arms (see Figure 24)

against the ramp plate, forcing moveable face toward fixed

face squeezing belt.

CVT

(Drive

Pulley)

Drive V-Belt

Driven

Pulley

CENTRIF

UGAL F

ORC

E

BEL

T

SQUEEZE

FORCE

FIXED

FACE

VARIABLE

FACE

DRIVE PULLEY

(CVT)