Vr-36ha — service information – Multiquip VR36HA User Manual

Page 53

VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06) — PAGE 53

VR-36HA — SERVICE INFORMATION

1.5. Hydraulic System

A good quality hydraulic oil should be used.

DO NOT USE MULTI-VISCOSITY OIL. Cleanliness is a very

important part of proper hydraulic system operation. Hydraulic

oil is not only used to transfer power; it also lubricates and cools

the system components. Keeping the hydraulic system clean

can help reduce costly repairs.

The hydraulic oil level sight glass is located on the right rear of

the front drum, below the engine compartment. This level should

be checked daily. Oil must be below the top and above the bottom

of the sight glass. DO NOT OVERFILL! Care should be taken to

clean the filler cap before adding oil to the system. If hydraulic oil

has to be added, the machine should be inspected for leaks.

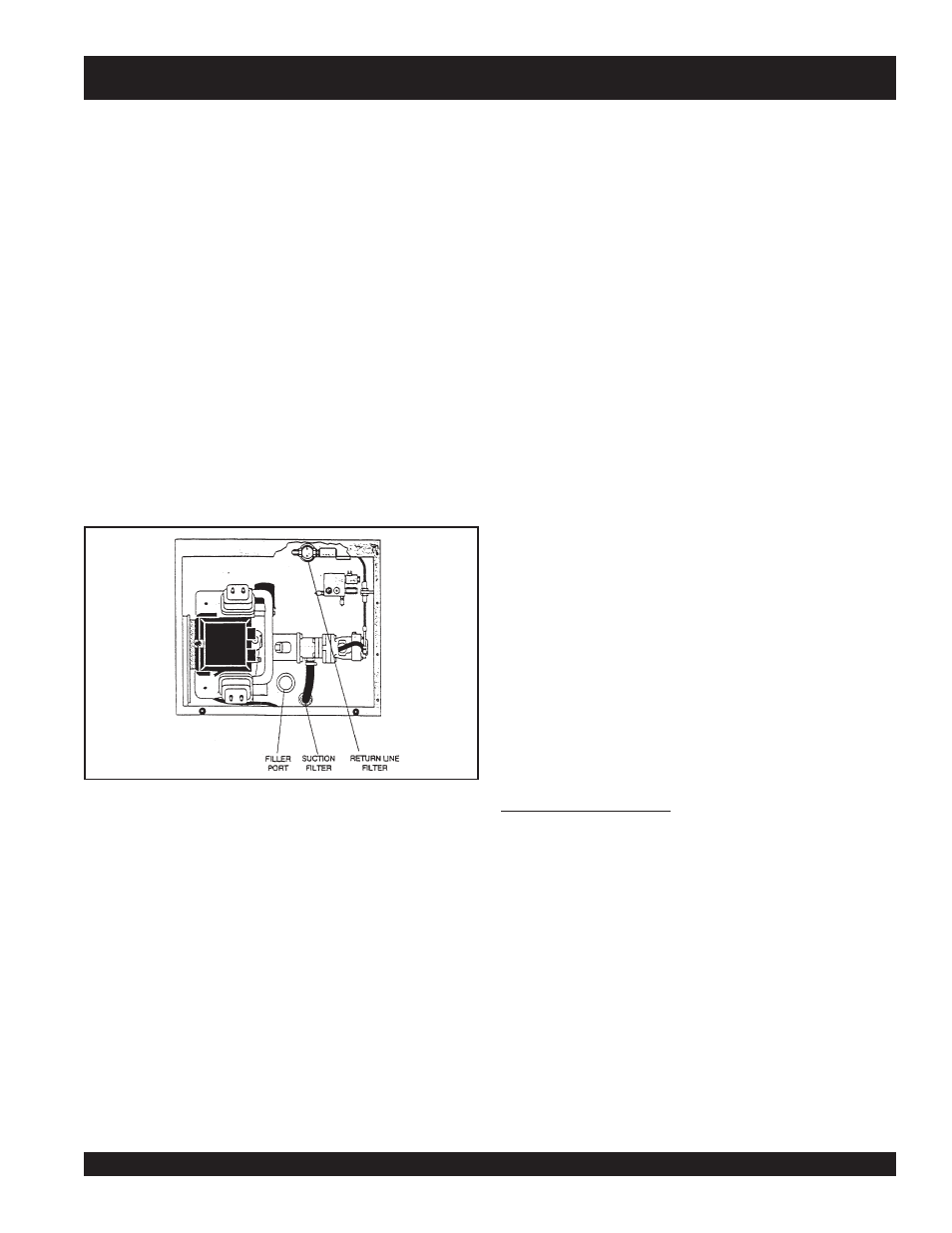

The suction filter is located in the hydraulic tank. This filter is

attached to the fitting connected to the hydraulic pump suction

hose.

The return filter is located at the front of the engine compartment.

Replace both filters according to the service chart.

1.6. Changing Hydraulic Oil And Filters

1.

Park the machine on a clean flat work area and set the

parking brake.

2.

Remove the drain plug and drain the hydraulic oil. Dispose

of the used oil in an environmentally friendly manner.

Replace the drain plug and tighten.

3.

Remove the return filter and install a new

filter. Dispose of the used filter in an environmentally friendly

manner.

4.

Disconnect the suction hose and remove the fitting from

the tank. Replace the suction filter. Dispose of the used

filter in an environmentally friendly manner. Replace the

fitting and reconnect the suction hose.

5.

Fill the hydraulic tank with the proper quantity and quality

required. See service chart for specifications.

6.

Place the forward / reverse control lever in the neutral

position. Start and run the engine at idle for approximately

3 to 5 minutes.

7.

Recheck the oil level and fill as required.

1.7. Scraper Bars And Cocoa Mats

The scraper bars are located on the rear of the front drum and

the front of the rear drum. Adjust the scrapers, using the slotted

holes provided. as close as possible to the drums.

The cocoa mats are located at the front of the front drum and the

rear of the rear drum. Cocoa mats should be replaced when

badly worn. Always pre-wet the cocoa mats before use.

1.8. Towing Valve

The hydraulic system has a towing valve allowing hydraulic oil

to by-pass. This lets the unit freewheel for emergency towing.

The towing valve should only be used in emergencies when the

machine cannot be driven due to engine or hydraulic system

problems.

When towing is complete, this valve

must

be closed completely

and the lock nut set. Failure to close this valve completely will

result in low power, improper speed, and excessive hydraulic oil

temperature.

WARNING: The towing valve is only for emergency use.

DO

NOT

tow unit over 2 MPH or long distance as hydraulic system

component failure could result.

2.0 HYDRAULIC SYSTEM

2.1 General

The hydraulic system consists of a two pump stack directly

coupled to the engine. A hydraulic valve block is provided for

quick and easy testing and troubleshooting.

Hydraulic oil is filtered by a screen filter located in the tank filler

neck, a 40 micron suction filter located in the tank, and a 10

micron return filter, with cold oil bypass valve located in the return

circuit.