Related products, About the servovalve, Servovalve functional – MTS Series 256 Servovalve User Manual

Page 14: Control signal, About the servovalve 14 servovalve functional 14

Series 256 Servovalve Product Information

14

Introduction

Related products

The Series 256 Servovalves includes a Series 252 Servovalve. See the Series 252

Servovalve Product Information manual (part number 011-182-906) for product-

specific information and maintenance procedures for the Series 252 Servovalve.

About the Servovalve

The heart of a servohydraulic system is the servovalve. It is the final control

element in most MTS closed-loop systems. The servovalve responds to

command signals generated by the software and processed by the controller and

output through the valve driver module. The servovalve regulates the direction

and flow of the hydraulic fluid entering the actuator from the hydraulic pressure

ports. The direction that the spools move determines the direction of fluid flow to

the actuator. A pressure difference is what causes the fluid to move.

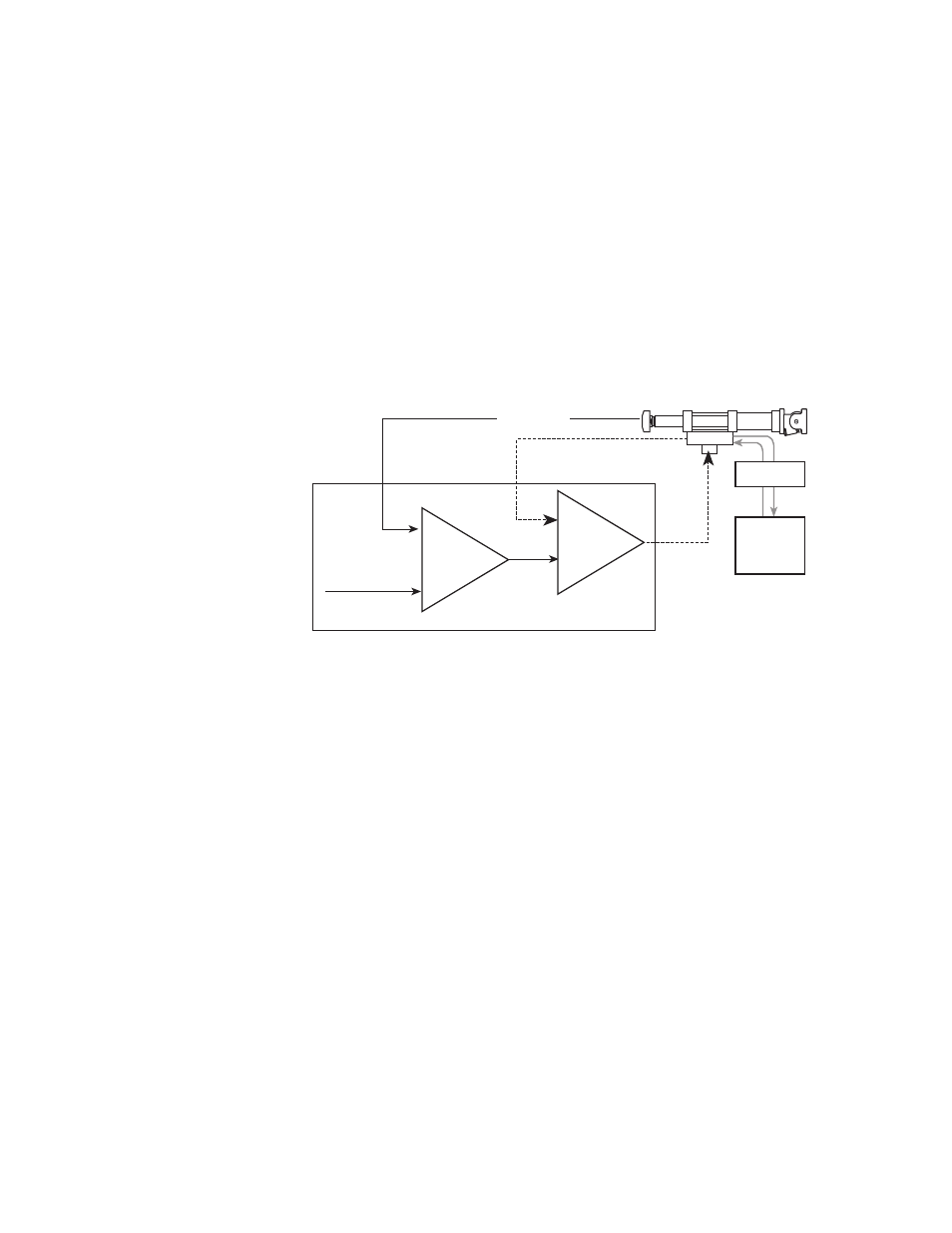

Typical Closed-Loop System

Servovalve Functional

Control signal

In a closed-loop hydraulic system, the Product Name uses the control signal from

an electronic control device (controller) to operate a valve that regulates the

movement of a hydraulic actuator.

The control signal is created by comparing the program command signal (the

desired actuator position) and the feedback signal from a transducer (the actual

actuator position). Any difference between the two is called DC error, which is

the command to the servovalve to supply hydraulic fluid to the actuator until the

desired actuator position is achieved.

Test

Command

Control

Signal

Inner

Loop

Outer

Loop

Manifold

Hydraulic

Power

Unit

Valve Driver

Feedback

Controller

Control

Mode