MTS Material Test Systems User Manual

Page 71

As a guideline, for a test system that operates eight hours per day, one week will equal 40 hours, and one

month will equal 160 hours. For a test system that operates up to 24 hours per day, one week will equal 160

hours and one month will equal 720 hours.

When to perform visual checks

Routine maintenance procedures that are scheduled on a daily or weekly basis usually involve visual checks

only, and should not interfere with the operation of your test system. These checks will help you assess which

procedures must be performed before running the next test. For example, the dirty filter indicator on the HPU

signals that it is time to clean or change the filter.

You can perform these visual checks at the start of each day and incorporate them into your preparations to

run a test.

Note:

It is highly unlikely (unless you are running an extremely long durability type of test) that you should

need to stop a test simply to perform a routine maintenance procedure.

Changing the intervals

You can change the time interval for performing maintenance checks, based on the operating conditions for

your system. Operating conditions that affect the maintenance schedule include air quality, temperature,

humidity, how often you run tests, and whether you use a pump room or a hydraulic power unit to supply

hydraulic fluid to the system. Keep a log to observe trends in your system, then adjust your maintenance

schedule as needed. For example, you might find that you do not have to perform daily checks of the hydraulic

fluid, and decide to check it once a week instead.

Additional maintenance

Because of the variations in system configurations, the maintenance schedule table lists the typical procedures

for the associated products. Additional maintenance procedures might be required depending on the specific

product model. Refer to the product manuals for complete maintenance information.

Additional maintenance procedures can be required whenever you notice decreased system performance.

An example of this type of maintenance is servovalve filter replacement. Many of these procedures require

additional training and should be performed by MTS service personnel.

Information about analyzing hydraulic fluid is contained in the MTS Fluid Care Guide that accompanies each

hydraulic power unit, and in the appendices of maintenance manuals

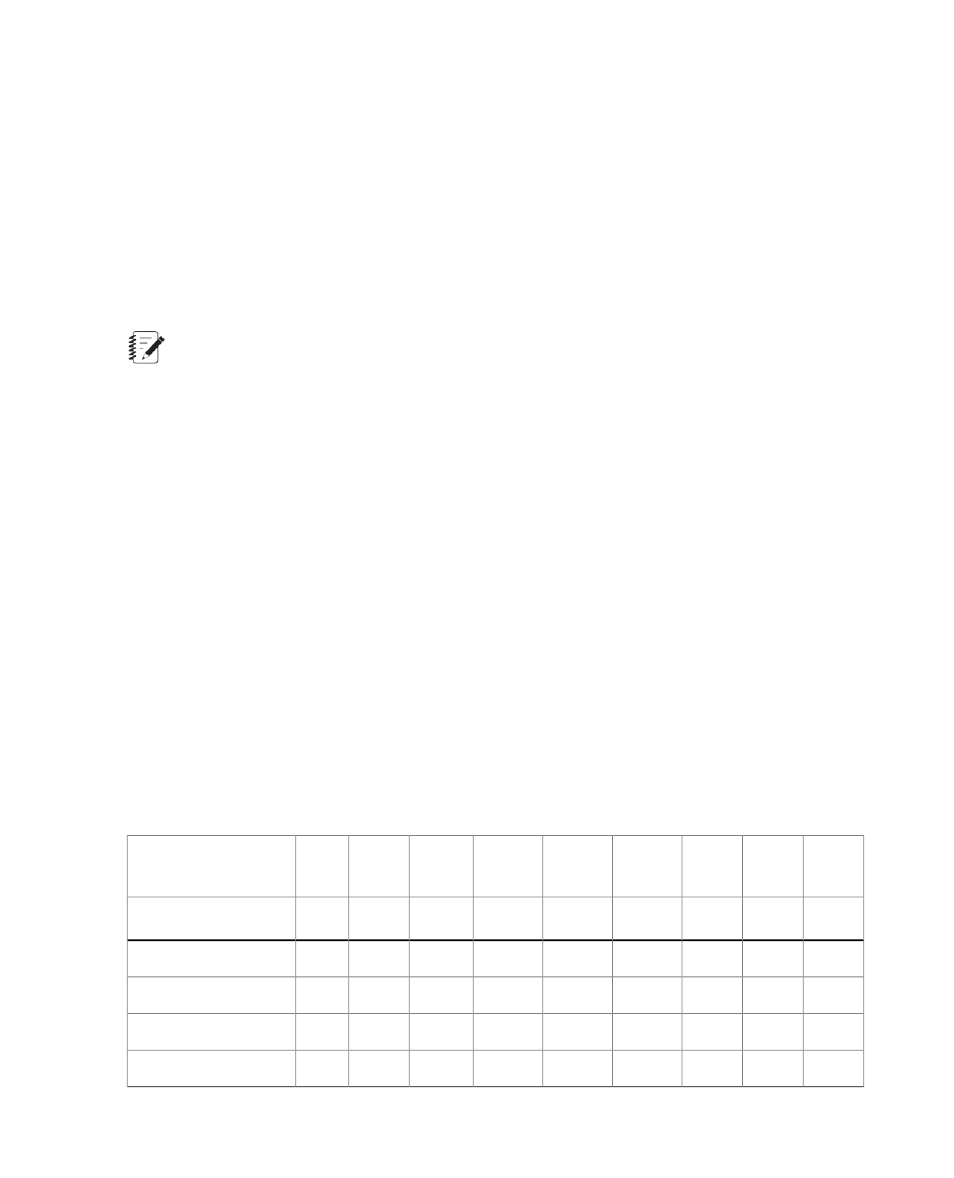

Table 12: Routine Maintenance

5 +

Years

2 Year

1 Year

6

months

3

months

2

months

1

Month

1

Week

Daily

Calendar time

10,000

4,000

2,000

1000

500

320

160

40

8

Running time - Hours

Hazard labels

X

Inspect for legibility

-

Replace as required

Hydraulic Hoses

MTS Material Test System Operation 71

8.0 Routine Maintenance