0 manual overview, 0 typical test system configuration, Manual overview – MTS Material Test Systems User Manual

Page 16: Typical test system configuration

3.1.0 Manual Overview

This manual provides operating guidelines, installation guidelines, and safety practices for operation of an

MTS Test System. This manuals deals primarily with the hardware components used to configure a typical

MTS load frame based materials testing system: the load frame, the grips and fixtures used to secure the

specimen during testing, and the MTS Hydraulic Power Unit. It also contains information on the MTS controller

and a general description of the test system control theory.

This manual does not contain information on the software used to create and run specific testing applications

such as low cycle fatigue or monotonic tension. For this information, refer to your software manuals; for

example TestSuite or TestWorks.

An MTS test system can be designed for a wide variety of testing applications. To provide maximum flexibility

for operation, the information in this manual is written for a typical system.

In addition to studying this manual, MTS recommends you become acquainted with the system by reading

the introductory sections of the product manuals.

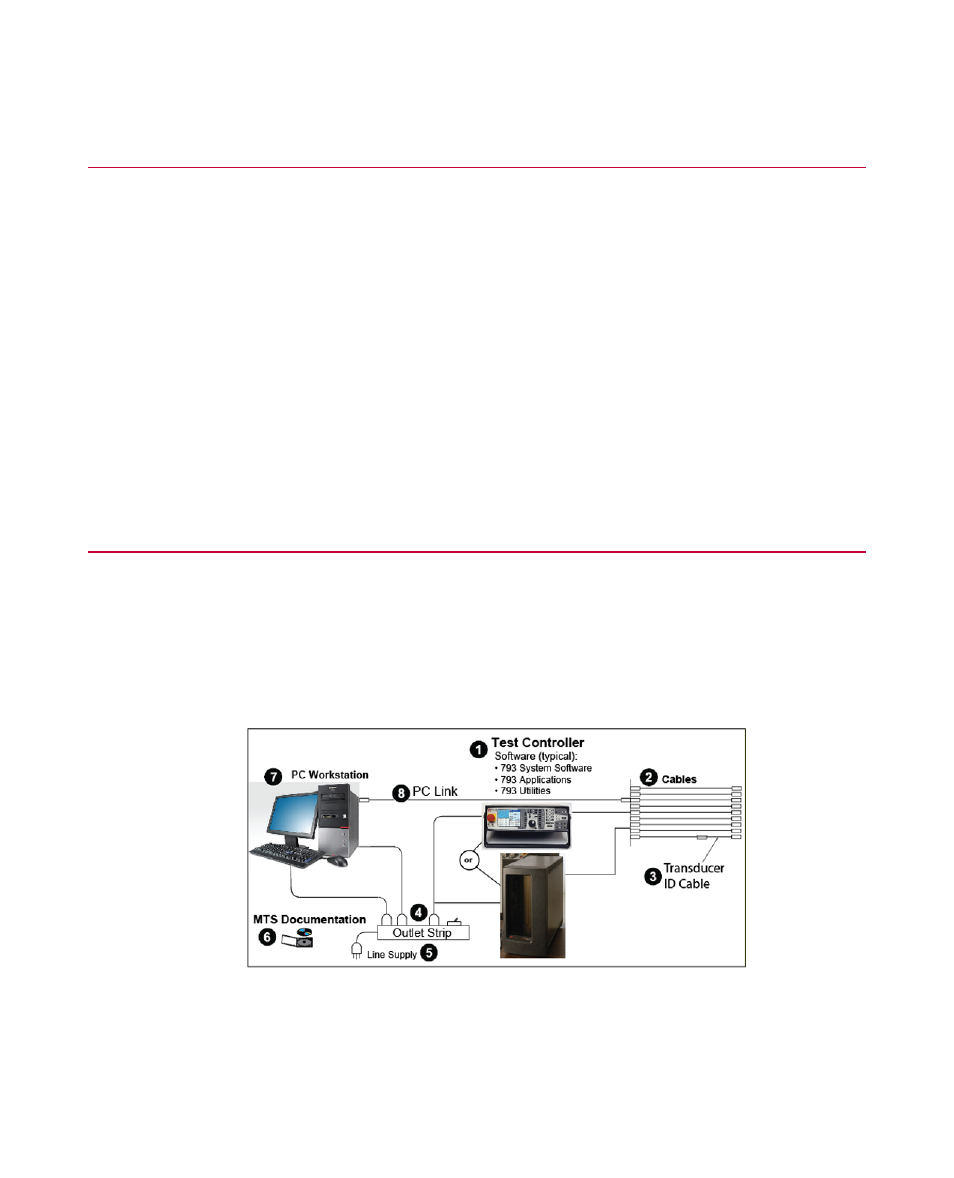

3.2.0 Typical Test System Configuration

An MTS Test System can be designed for a wide variety of testing applications. To provide maximum flexibility

for operation, the information in this manual is written for the typical system that includes as a minimum

configuration a test controller, load frame, and hydraulic power unit.

The following illustrations show the common system components and uses the MTS Landmark load frame

for illustration purposes. All MTS load frames have similar components. Some load frames will have a t-slot

tables as a baseplate to accommodate various fixtures and actuator and column positioning.

Figure 1: Test Controller and Components

16 MTS Material Test System Operation

3.0 Introduction