Series 642 bend fixture component identification – MTS Series 642 Bend Fixtures User Manual

Page 14

Series 642 Bend Fixtures Product Information

14

Introduction

The 642.01, 642.10, and 642.25 can be configured for three-point or four-point

loading. Four-point loading uses two roller block assemblies in the upper

bedplate and two in the lower bedplate. Three-point loading uses two roller block

assemblies in the lower bedplate and a three-point option kit attached to the load

cell.

Different diameter rollers can be used with the same roller block assemblies.

Standard roller diameters are 0.125, 0.250, 0.375, 0.500, 0.750, 1.0, 1.25, 1.5,

1.75, and 2.0 inch, as well as 5, 8, 10, 12, 20, 30, 40, and 50 millimeter (see the

tables on pages 14–18 for individual model standard diameters). MTS can also

build rollers with custom sizes. See your sales representative if you require

rollers of non-standard size.

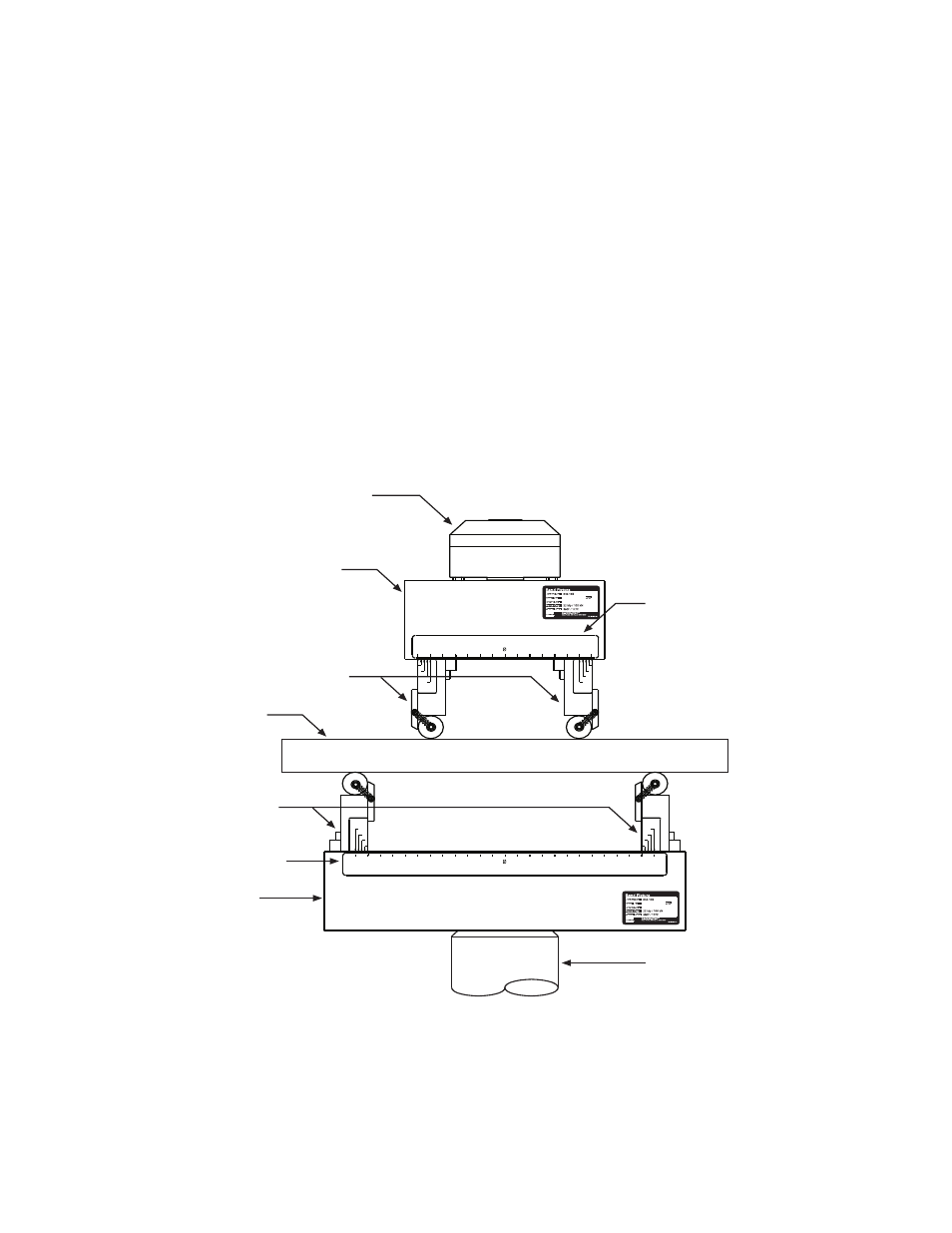

Series 642 Bend Fixture Component Identification

The following illustrations identify the Model 642 Bend Fixture’s major

components in various models and configurations.

Series 642 Bend Fixture Major Components—Four-Point Loading Configuration

Force Transducer

Upper Bedplate

Adjustable Roller Blocks

Upper Scale

Actuator

Lower

Bedplate

Lower Scale

Adjustable Roller

Blocks

Specimen