Selecting face surfaces, Selecting face surfaces 40 – MTS Advantage Pneumatic Grips User Manual

Page 40

Advantage™ Pneumatic Grips

Selecting Face Surfaces

Operation

40

Selecting Face Surfaces

A face is a type of surface attachment for the Advantage Pneumatic grips. There

are a variety of surface coatings to accommodate a variety of specimens. The

following tables will help you determine which face is suitable for a specific type

of specimen.

Note

You are responsible for matching the appropriate face with the type of

specimen you intend to test.

Once you have determined the grip surface, refer to the following to select the

proper face for your grip:

•

“Grip Faces for the 10 N Grips”

•

“Grip Faces for the 200 N and 2000 N Grips”

•

“Grip Faces for the 10,000 N Grips”

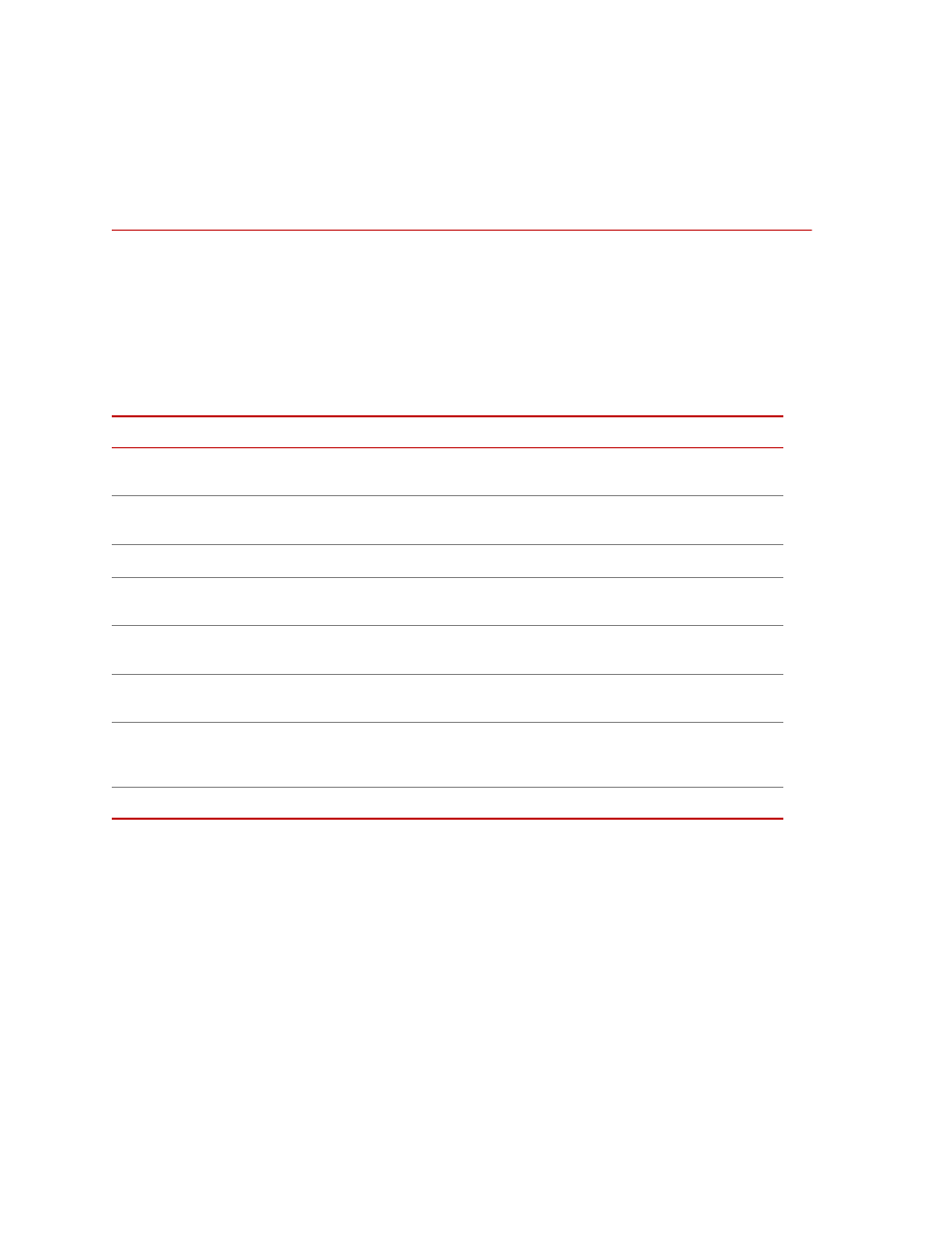

Face Surface Usage Guidelines

Face Surface

Usage

Corrugated

Gripping smooth specimens such as textile, fabrics, tissue, leather, and

other smooth materials.

Serrated

Gripping soft materials such as paper, board, aluminum, copper, steel

wire, and soft steels without causing failure.

Smooth rubber coated

*

* In some cases the smooth faces will slip below the rated capacity of the grip.

Offers extra protection for thin specimens such as plastic films.

Rubber matte

Offers more gripping power than smooth rubber coated faces and are more

resistant to abrasive specimens.

Rubber corrugated

Offers more gripping power than smooth rubber matte faces and protects

thin flexible specimens.

Diamond tipped

Provides an aggressive gripping surface for gripping soft materials such as

soft steels, rigid plastic, and wood.

Grab test

Gripping fabrics such as leather and woven fabrics. The grab test face is

used in accordance with international ASTM D5034, ASTM D7683,

ASTM D2208, and ISO 5082.

Line contact

Gripping rubber, latex, and cable sheath.