MTS Series 609 Alignment Fixture User Manual

Page 59

Adjust the Concentric Alignment

Series 609 Alignment Fixture Product Information

Alignment Procedure

59

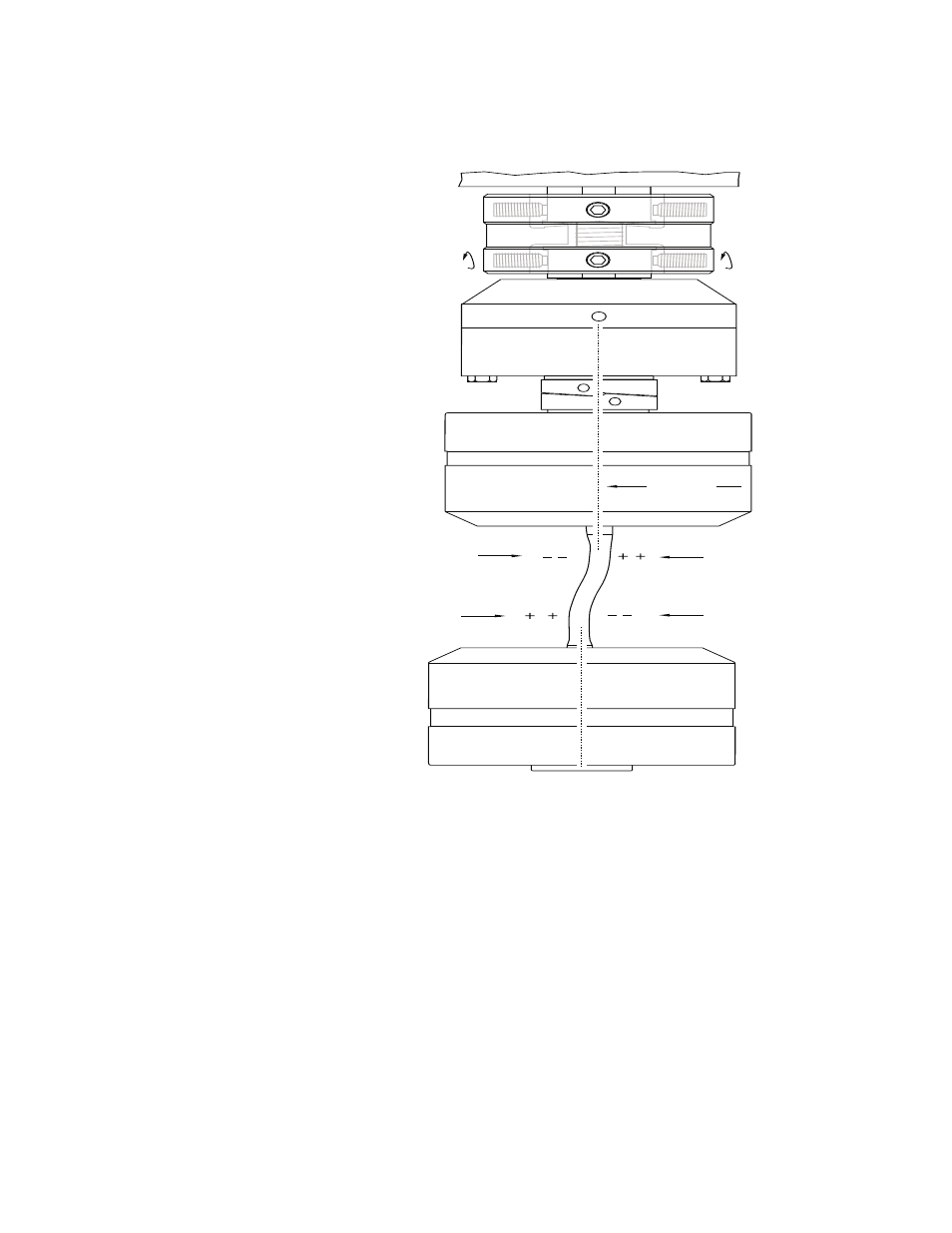

3. Using the following figure, determine which screws to adjust.

•

If you are making minor adjustments, keep all four screws in contact

with the concentricity collar.

•

If you are making adjustments of 75 µS or more, loosen the opposing

screws. Tighten one to get a reading slightly beyond your goal. Tighten

the other to reach your goal. End with all screws tight.

•

If you are adjusting a round specimen, see “Round Specimens—

Reduce the “S” Bend.”

•

If you are adjusting a flat specimen, see “Thin Flat Specimens –

Reduce the “S” Bend.”

You should end up with readings characteristic of the remaining “C” bend—

uniformly higher readings on one side of the specimen and uniformly lower

readings on the specimen’s opposite side.

The following figure shows typical readings before and after an adjustment.

This figure shows how

turning the concentricity

adjustment screws affects

strain gage readings.

Note

If the screws can

not be adjusted,

reduce the preload

by 50%

Loosen

Tighten

Move

This reading

moves

negative

This reading

moves

positive

This reading moves positive

This reading moves negative