Where – MTS Series 609 Alignment Fixture User Manual

Page 35

Calculating Bending Strain—Round Thin Diameter

Series 609 Alignment Fixture Product Information

Specimen Preparation

35

Calculating Bending Strain—Round Thin Diameter Specimens

This section shows how to calculate the bending strain for round specimens with

three gages at each level.

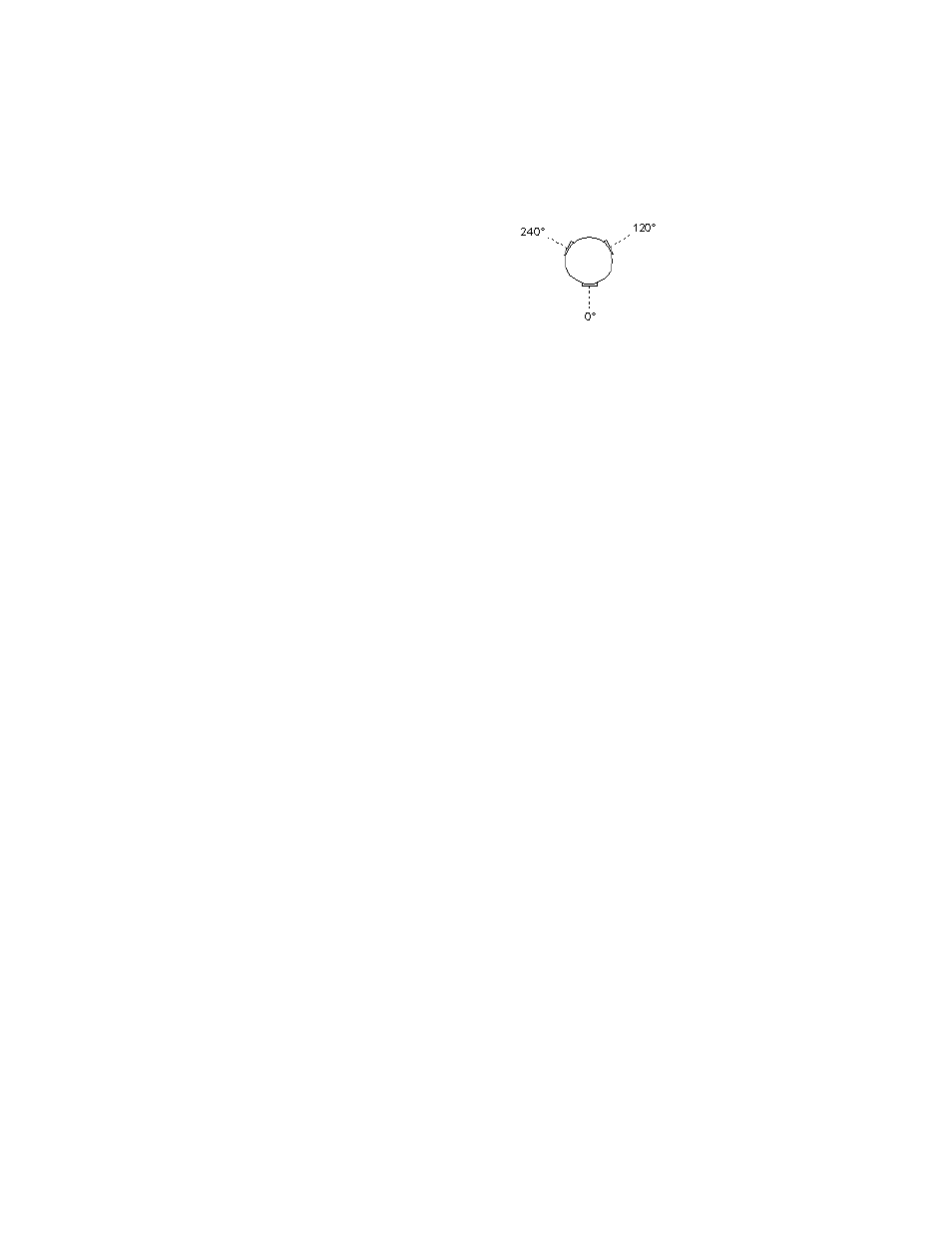

Gage Placement

1. Calculate the average axial strain for each level.

Use this formula to find the average axial strain (A):

Where:

ε

1

through

ε

9

are the strain readings from gages 1 through 9

Au is the average strain of the upper gages

Am is the average strain of the middle gages

Al is the average strain of the lower gages

2. Calculate the bending strain for each axis and each level.

Use these formulas to determine the bending strain (B):

Where:

ε

1

through

ε

9

are the strain readings from gages 1 through 9

bu is the bending strain of the upper gages

bm is the bending strain of the middle gages

bl is the bending strain of the lower gages

subscript

0

is the bending strain of the 0° axis

subscript

120

is the bending strain of the 120° axis

subscript

240

is the bending strain of the 240° axis

3. Determine the tensile direction for each level.

Determine the two most positive (tensile) results for each level from Step 2.

•

Call the largest b

1

.

•

Call the second largest b

2

.

Au

ε

1

ε

2

ε

3

+

+

3

----------------------------

=

Am

ε

4

ε

5

ε

6

+

+

3

----------------------------

=

Al

ε

7

ε

8

ε

9

+

+

3

----------------------------

=

Upper Gages

Middle Gages

Lower Gages

bu

0

°

ε

1

A

–

=

bu

120

°

ε

2

A

–

=

bu

240

°

ε

3

A

–

=

bm

0

°

ε

4

A

–

=

bm

120

°

ε

5

A

–

=

bm

240

°

ε

6

A

–

=

bl

0

°

ε

7

A

–

=

bl

120

°

ε

8

A

–

=

bl

240

°

ε

9

A

–

=

Upper Gages

Middle Gages

Lower Gages