Vertical seam – Metal Sales Vertical Seam Manual User Manual

Page 17

PVS-17

VERTICAL SEAM

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Office) • www.metalsales.us.com

d

esign

/ i

nsTallaTion

C

onsideraTions

(

ConT

)

Steel roofing panels are subject to dimensional changes after installation due to exposure to varying temperatures. The greatest

influence is solar energy. Steel roofing absorbs various amounts of heat depending upon color, finish, angle of exposure, and

time of exposure.

The relationship of ambient temperature to building structural temperature must be considered when designing a Vertical Seam

roof system. The floating clips for the Vertical Seam panels are designed for expansion and contraction of the panels in the

longitudinal direction. Lateral expansion and contraction is accommodated by the configuration of the panel cross section and

causes negligible panel movement.

When the total length of panel run exceeds the capability of the clips to accommodate the thermal movement, expansion joints

must be designed into the structure.

SYSTEM EXPANSION / CONTRACTION

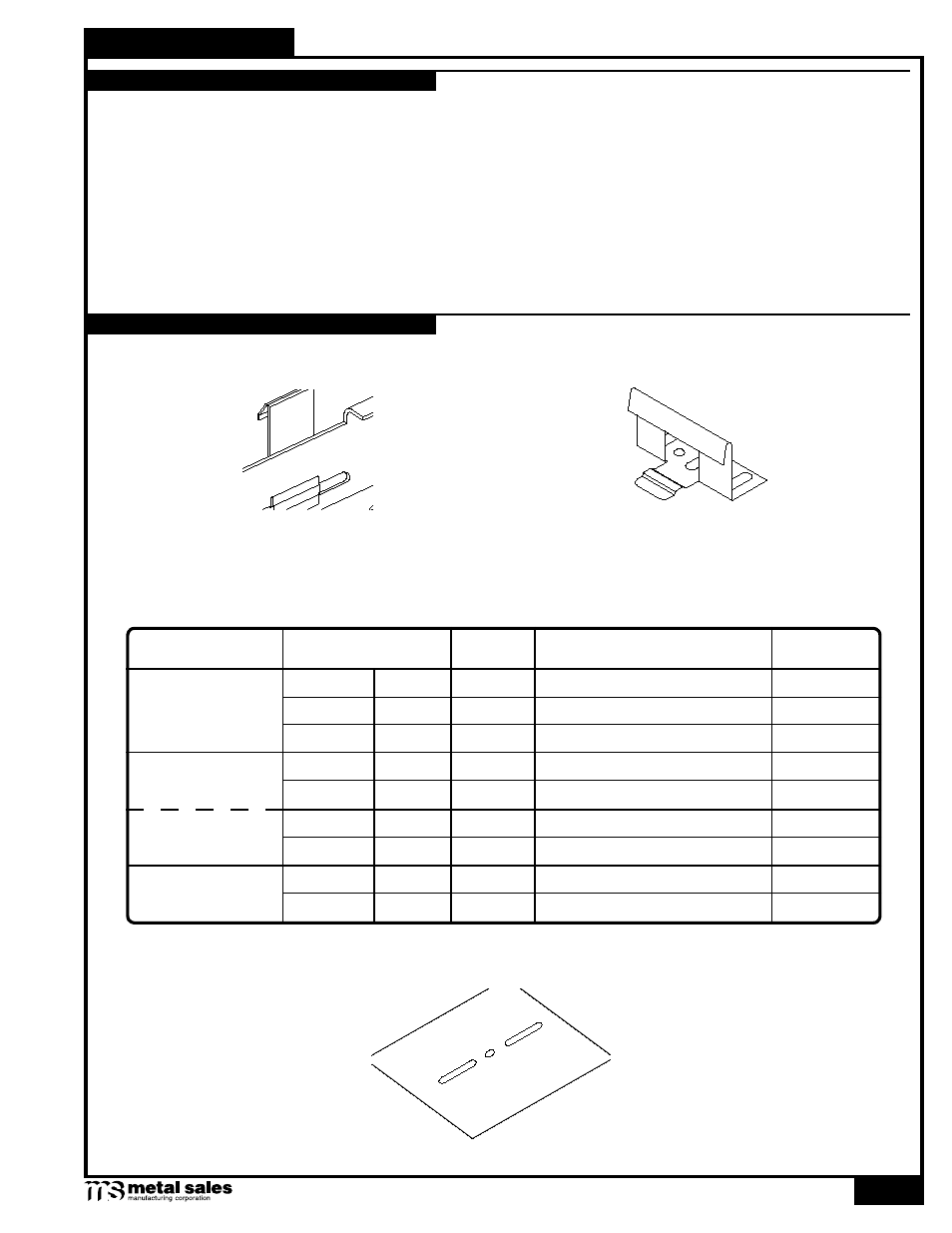

Vertical Seam Clip

Vertical Seam panel clips - Clips are placed along the male leg of each panel prior to installing adjacent panels. Design wind

uplift must be considered for proper clip spacing.

The following chart should be used to determine proper fasteners required for clip installation on the selected applications.

(See Fastener Selection Guide page 16 for other fasteners available.)

* Length of Deck Screw will vary depending on the total thickness of the rigid insulation and metal.

** Contact your local Metal Sales branch representative for more information (see pages 2 and 3).

*** 12" Panel Only

Vertical Seam UL-90 Clip

(2 fasteners required)

Flat Bearing Plate

SELECTION OF SYSTEM COMPONENTS

2 FASTENERS

2 FASTENERS

CLIP OVER RIGID

INSULATION /

METAL DECK

2 FASTENERS

2 FASTENERS

#10 X 1" PANCAKE HEAD DRILLER

#10 X 1" PANCAKE HEAD DRILLER

# REQ.

TYPE OF FASTENER

APPLICATION

INSTALLATION

REQUIREMENTS

22 GAUGE

24 GAUGE

**CLIP

SPACING

4'-0" O.C.

4'-0" O.C.

CLIPS

OVER PURLINS

(16 GA. MIN)

CLIPS OVER

5

/

8

" WOOD DECK

24 GAUGE

UL-90

2 FASTENERS

UL-90

22 GAUGE

DECK SCREW #14*

DECK SCREW #14*

2 FASTENERS

#10 X 1" PANCAKE HEAD WOOD

#10 X 1" PANCAKE HEAD WOOD

22 GAUGE

24 GAUGE

UL-90

UL-90

UL-90

UL-90

4'-0" O.C.

4'-0" O.C.

4'-0" O.C.

4'-0" O.C.

#10 X 1" PANCAKE HEAD DRILLER

22 GAUGE

5'-0" O.C.***

UL-90

2 FASTENERS

1 FASTENER

1 FASTENER

#10 X 1" PANCAKE HEAD WOOD

#10 X 1" PANCAKE HEAD WOOD

22 GAUGE

24 GAUGE

Standard clip

Standard clip

1'-6" O.C.

1'-6" O.C.

Max suction

pressure of 32 psf