Vertical seam, Ul 580 w – Metal Sales Vertical Seam Manual User Manual

Page 11

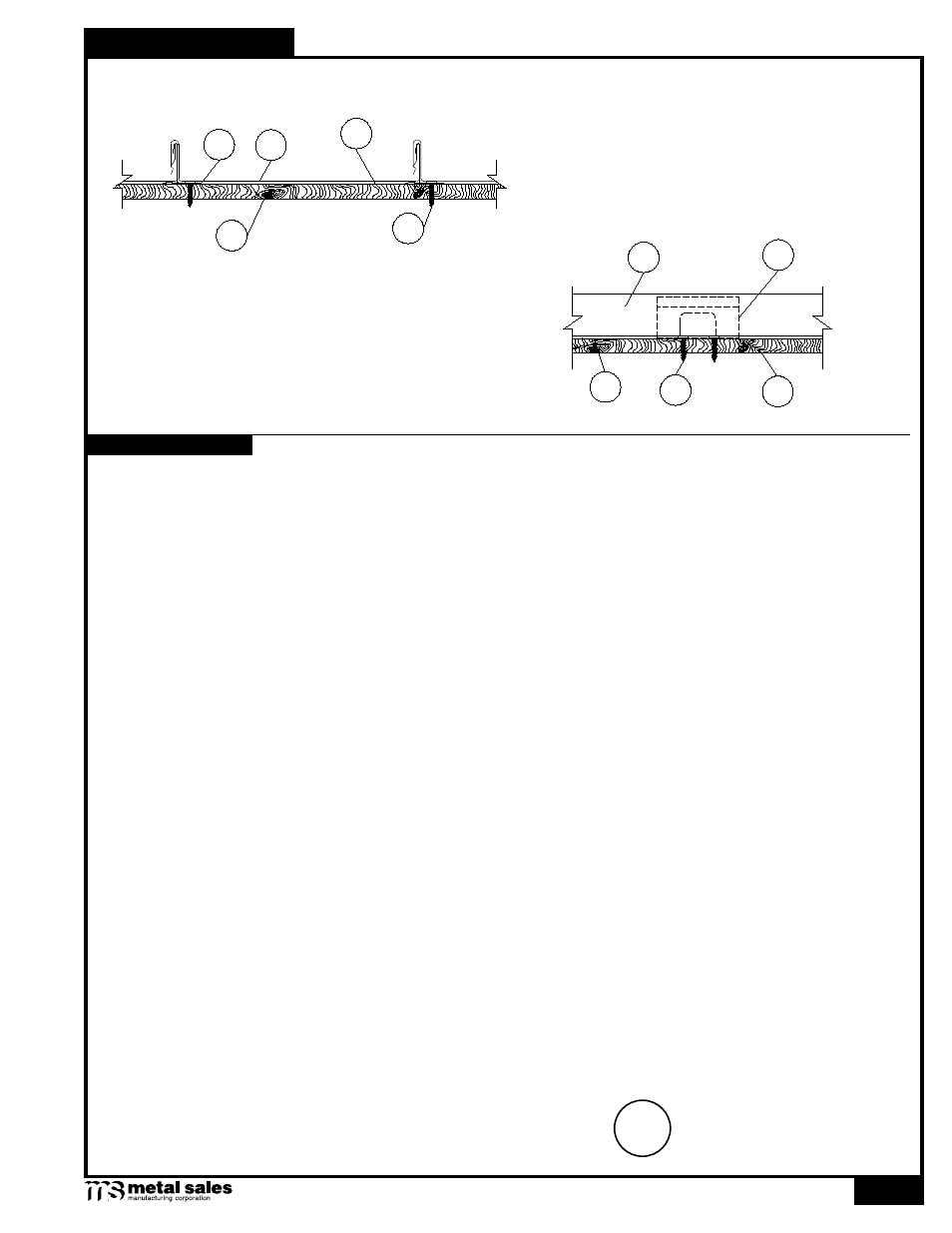

Construction No. 343

December 07, 2001

Uplift - Class 90

Fire Not Investigated

1. Metal Roof Deck Panels* No. 24 MSG min coated steel. Panel width 18 in. max., 10 in. min. Rib height 1-3/4 in.

at female side. Panels continuous over three or more clips with no endlaps. A bead of sealant may be used at panel

side joints.

METAL SALES MANUFACTURING CORPORATION

- “Vertical Seam”

2. Roof Deck Fasteners*(Panel Clips) One piece assembly, 3-1/2 in. wide, 1-7/8 in. high. Min thickness No. 18

MSG. Clips spaced 36 in. OC, max, fastened to plywood deck.

METAL SALES MANUFACTURING CORPORATION

- “Vertical Seam Clip”

3. Fasteners (Screws) Fasteners used to attach panel clips (Item 2) to plywood to be No. 10-12 by 1 in. long pan-

cake head, No. 2 Phillips drive, A-point, coated steel screw. Min two fasteners per clip to be used.

4. Underlayment used over plywood deck to be Type 15 or 30 organic felt. Sides overlapped min 2 in., end laps

per manufacturer’s instructions. Felt nailed to plywood deck with 1-1/4 in. long steel cap nails, located per manu-

facturer’s instructions. Nail spacing to be max 12 in. OC at the side lap and max 24 in. OC in interior rows.

As An

Alternate A self-adhering modified bitumen water proofing membrane may be used, installed per manufacturer’s

instructions. Note - when alternate is used the plywood joints need not be sealed.

5. Plywood Decking to be graded per PS83 specifications, 19/32 in. thick, exposure 1, APA Rated Sheathing

(42/20) square edged. Butt ends not blocked. All butt and side joints to be sealed with a one part urethane caulk

sealant applied with a caulking gun and feathered outward from the joint. (Note exception under Item No. 4, Alter-

nate.)

6. Supports (Not Shown)-Spaced max of 24 in. OC. Any of the following types may be used to support the plywood

decking:

a) Nom 2 by 6 in., No. 2 grade or better S-P-F, Hemlock Fir, Douglas Fir or Southern Yellow Pine or equivalent.

b) Wood trusses with a nom 2 by 4 in. upper chord of the same grade as item a.

c) No. 22 MSG min cold formed coated steel (min yield to be 33,000 psi).

7. Plywood Fasteners (Not Shown)-Fasteners used to attach the plywood deck to the supports to be as follows:

a) For plywood-to-wood supports No. 8-18 by 1-7/8 in. long bugle-head steel screws with a No. 2 Phillips drive, a

“Hi-Low” thread pattern and an “S-Point”.

b) As an alternate to Item a, 8d common nails may be used.

c) For plywood-to-steel supports for a steel thickness less than No. 20 MSG No. 7-19 by 1-1/4 in. long bugle-head

steel screws with a No. 2 Phillips head drive “Hi-Low” threads and an “S-Point”. For a steel thickness greater than

No. 20 MSG to No. 16 MSG, No. 6-20 by 1-1/4 in. long bugle-head steel screws with a No. 2 Phillips drive and a S12

(TEK/3) supR point.

Spacing: Fastener spacing for all fastener types to be 6 in. OC at the plywood edges and 12 in. OC in the interior.

Refer to General information, Roof Deck Construction (Building Materials Directory) for items not evaluated.

*Bearing the UL Classification Mark

Underwriters Laboratories Inc.

®

UL

®

LISTED

1

2

5

4

3

1

2

3

4

5

PVS-11

VERTICAL SEAM

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Office) • www.metalsales.us.com

Ul 580 w

ind

U

PlifT

i

nformaTion

(

ConT

.)