1 motors, 4 repair, 5 disposal – Lenze g500 User Manual

Page 34: Motors, Repair, Disposal, Maintenance

Maintenance

Repair

Motors

EN

34

Lenze ¯ MA 12.0014 ¯ 1.0

7.3.1

Motors

Drain condensation

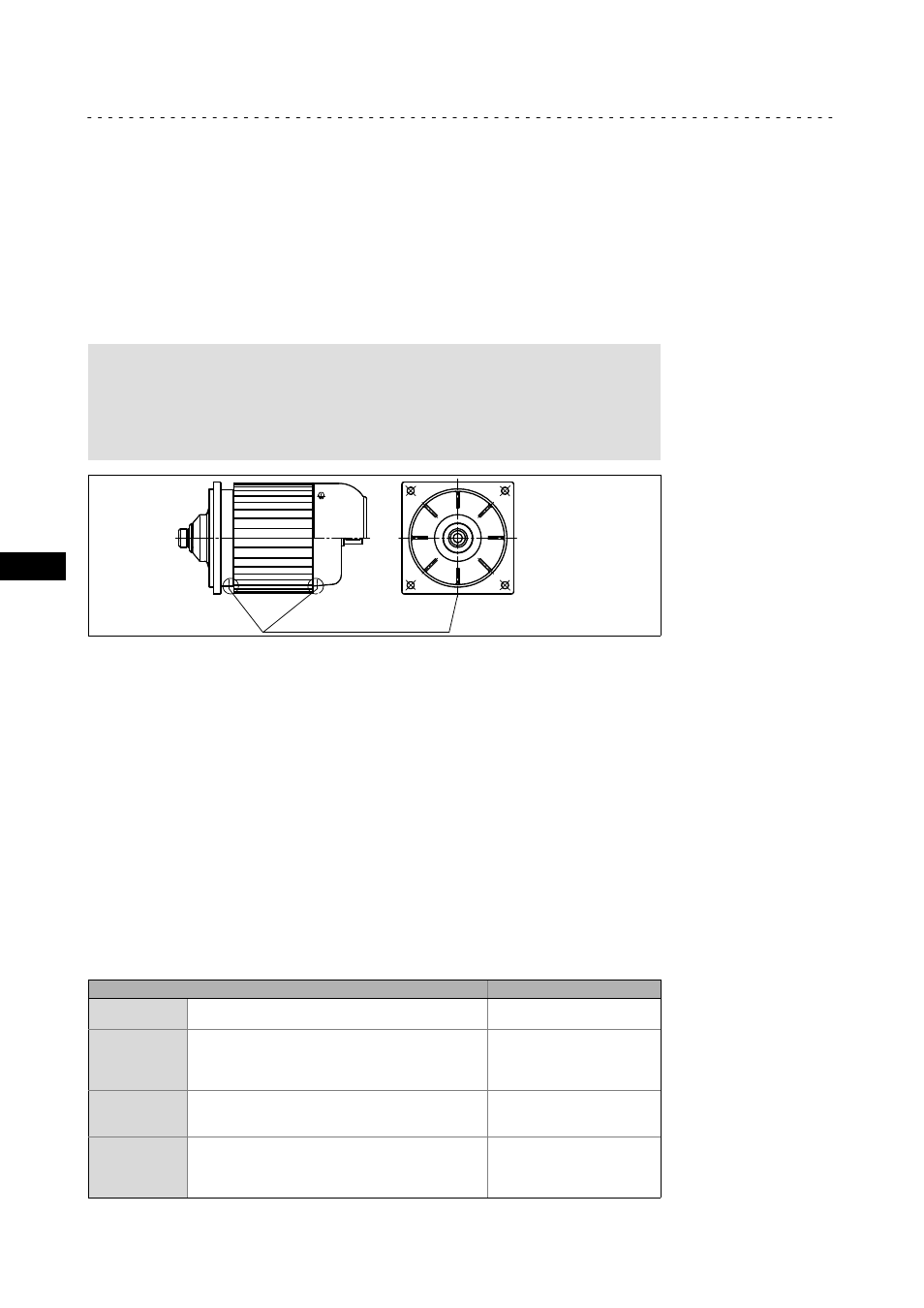

Depending on the mounting position, the condensation drain holes are always at the

bottom of the motor!

¯

For condensate drainage

–

the motor must be deenergised;

–

the plugs (screws) must be removed.

(

Stop!

To restore the enclosure, re−insert the plugs (screws) after condensate

drainage. If the condensation drain holes are not sealed again, the IP

enclosure of the motor will be reduced. For horinzontal motor shafts to

IP23 and for vertical motor shafts to IP20.

0

Fig. 11

Motor with condensation drain holes

0

Condensation drain holes

7.4

Repair

¯

We recommend that all repairs are carried out by the Lenze customer service.

7.5

Disposal

Protect the environment! Packing material can be recycled. Dispose of your separated

resources according to the waste disposal regulations or via a waste management

company.

The following table provides recommendations for an environmentally friendly

disposal of the machine and its components.

What?

Where?

Transport

material

Pallets

Return to the manufacturer or

forwarder

Packaging material

Cardboard box to waste paper

Plastics to plastics recycling or

residual waste

Reuse or dispose of wood wool

Lubricants

Oil, grease

Detergents and solvents

Paint residues

Dispose according to current

regulations

Components

Housing:

Bearings, gear wheel shafts:

Seals, electronic scrap

Cast iron, aluminium,

copper

Steel

Hazardous waste

Separate valuable substances

and dispose