3 coupling hubs, Coupling hubs, Mechanical installation – Lenze g500 User Manual

Page 15: Mounting coupling hubs, En 15, 3 coupling hubs general

Mechanical installation

Mounting

Coupling hubs

EN

15

Lenze ¯ MA 12.0014 ¯ 1.0

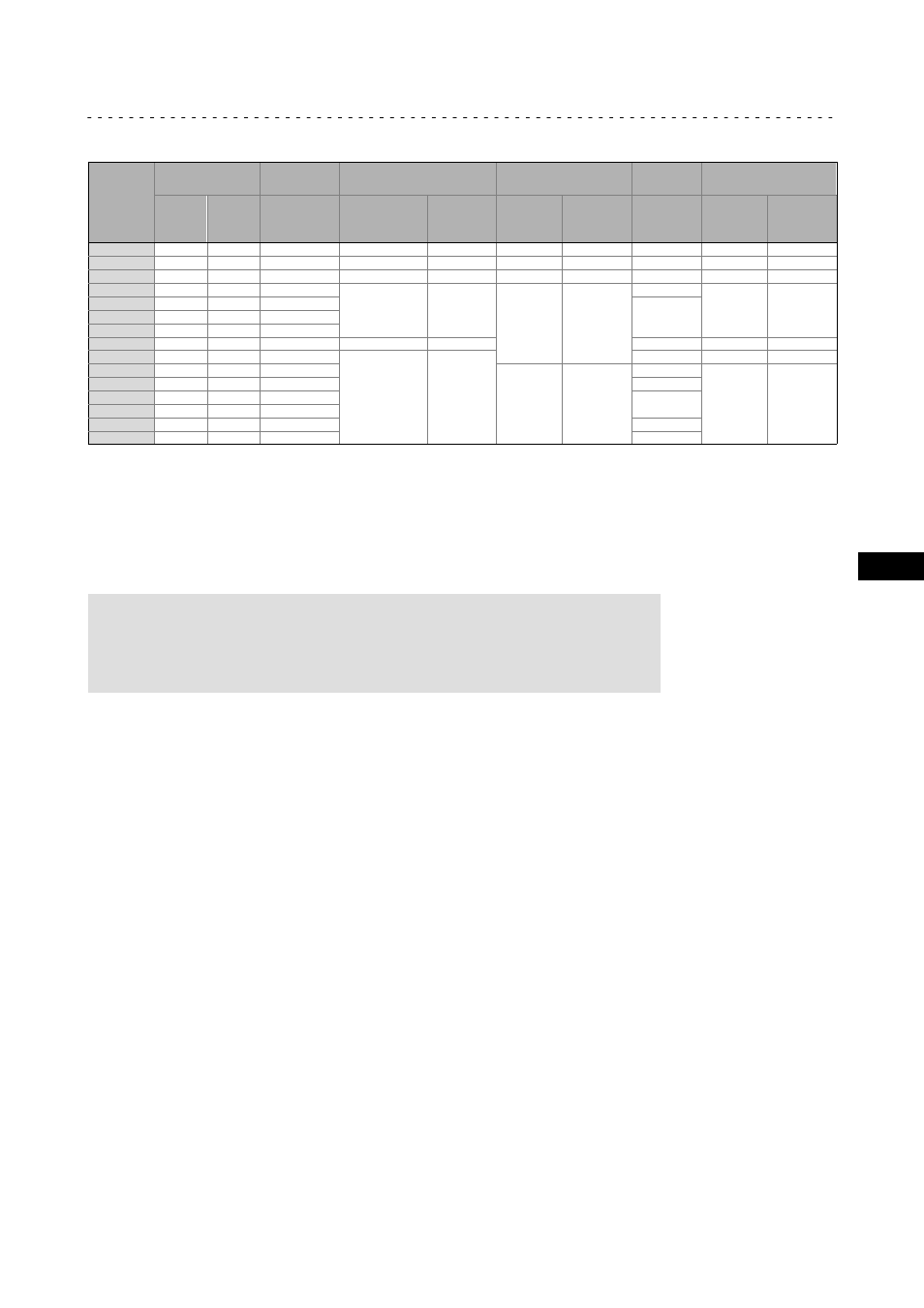

Drive size

Motor shaft

Assembly

dimension

Standard hub

Locking screw

Clamping hub

Key

1)

Clamping ring hub

D

[ mm ]

max. l

[ mm ]

M

[ mm ]

Thread

[ mm ]

Tightening

torque

[ Nm ]

Thread

[ mm ]

Tightening

torque

[ Nm ]

DIN

6885/1

[ mm ]

Thread

[ mm ]

Tightening

torque

[ Nm ]

1A

11

23

23

M4

1.5

M3

1.34

*

M3

1.34

1B

14

40

25

M5

2.0

M6

10.5

B5 x 5 x 16

M4

2.9

2B

11

23

23

M4

1.5

M3

1.34

*

M3

1.34

1C

19

40

25

M5

2.0

M6

10.5

B6 x 6 x 16

M4

2.9

2C

14

40

25

B5 x 5 x 16

3C

14

40

25

4C

14

40

25

6C

11

40

25

−−−

−−−

*

−−−

−−−

7C

19

40

25

M5

2.0

B6 x 6 x 16

M4

2.9

1D

24

60

30

M6

10.5

B8 x 7 x 18

M5

6

2D

19

60

30

B6 x 6 x 18

1E

28

60

30

B8 x 7 x 18

2E

24

60

30

3E

19

60

30

B6 x 6 x 18

4E

24

50

50

*

Tab. 2

Attachment of motors to gearboxes with mounting flange

* Use original key for the motor

1)

Key for standard hub and clamping hub

4.4.3

Coupling hubs

General

)

Note!

Standard hubs, clamping hubs and clamping ring hubs are

maintenance−free.We recommend checking the star−shaped spider and

system components when inspecting the drive.

Mounting the standard hub / clamping hub

1. Fit motor key (2).

–

Fit enclosed key for drive sizes

LC, LE, LF.

2. Push the coupling hub over the motor shaft, mounting dimension m (see Fig. 2

and Tab. 2) must be observed.

3. Secure coupling hub against axial movement using the fixing screw or clamping

screw (1).

4. Lay spider in the coupling claw on the gearbox side.

5. Align claws of the motor−side coupling hub with its counterpart.

6. Slowly push on motor, and bolt on to the gearbox flange.