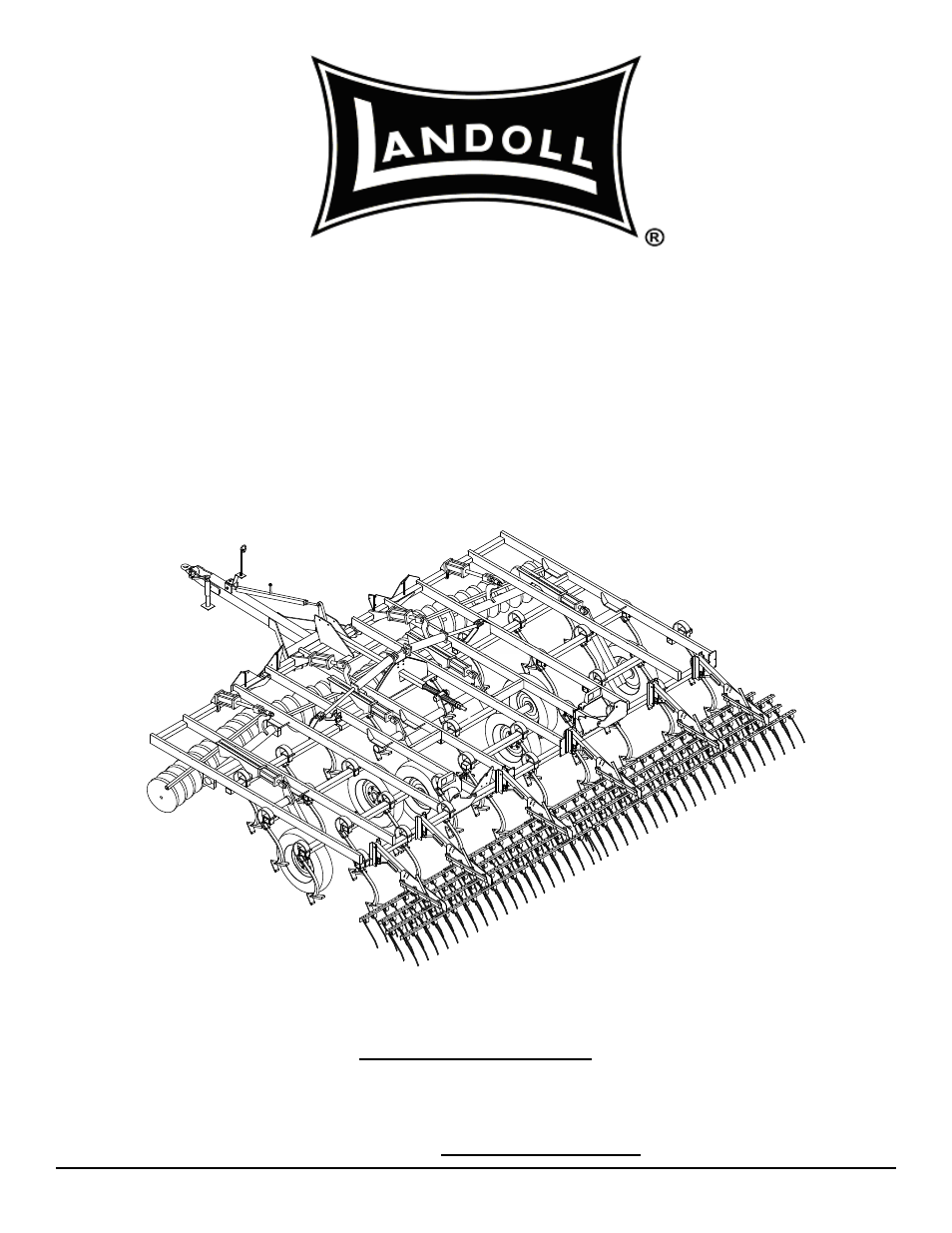

Landoll 855 Series Finisholl User Manual

Landoll Special machinery

This manual is related to the following products:

Table of contents

Document Outline

- Introduction

- Standard Specifications

- Table 2-1: General Torque Specifications

- Table 2-2: Hydraulic Fitting Torque Specifications

- Figure 2-1: 11’ Shank Placement Assembly

- Figure 2-2: 14’ Shank Placement Assembly

- Figure 2-3: 16’-8”Shank Placement Assembly (1 of 2)

- Figure 2-4: 16’-8” Shank Placement Assembly (2 of 2)

- Figure 2-5: 19’-4” Shank Placement Assembly (1 of 2)

- Figure 2-6: 19’-4” Shank Placement Assembly (2 of 2)

- Figure 2-7: 22’ Shank Placement Assembly (1 of 2)

- Figure 2-8: 22’ Shank Placement Assembly (2 of 2)

- Figure 2-9: 24’-8” Shank Placement Assembly (1 of 2)

- Figure 2-10: 24’-8” Shank Placement Assembly (2 of 2)

- Figure 2-11: 27’-4” Shank Placement Assembly (1 of 2)

- Figure 2-12: 27’-4” Shank Placement Assembly (2 of 2)

- Figure 2-13: 30’ Shank Placement Assembly (1 of 2)

- Figure 2-14: 30’ Shank Placement Assembly (2 of 2)

- Figure 2-15: 33’NShank Placement Assembly (1 of 2)

- Figure 2-16: 33’N Shank Placement Assembly (2 of 2)

- Figure 2-17: 33’ Shank Placement Assembly (1 of 2)

- Figure 2-18: 33’ Shank Placement Assembly (2 of 2)

- Figure 2-19: 35’ Shank Placement Assembly (1 of 2)

- Figure 2-20: 35’ Shank Placement Assembly (2 of 2)

- Figure 2-21: 41’ Shank Placement Assembly (1 of 4) (Left Outer Wing)

- Figure 2-22: 41’ Shank Placement Assembly (2 of 4) (Left Inner Wing and Left Half Main Frame)

- Figure 2-23: 41’Shank Placement Assembly (3 of 4) (Right Inner Wing and Right Half Main Frame)

- Figure 2-24: 41’ Shank Placement Assembly (4 of 4) (Right Outer Wing)

- Assembly Instructions

- Figure 3-1: Frame Assembly (30’ to 41’ Models)

- Frame Assembly (11’ Through 27’ Models)

- Frame Assembly (30’ Through 41’ Models)

- Rockshaft Installation, Frame

- Wings and Extensions Installation

- Rockshaft Installation, Wings

- Hydraulic Installation

- Figure 3-8: Master and Slave Cylinder Installation

- Figure 3-9: Fold Cylinder Bracket (17’ through 27’)

- Figure 3-10: Fold Cylinder Bracket (30’ and Larger)

- Figure 3-11: Hydraulic Installation (11’ - 14’ Models)

- Figure 3-12: Hydraulic Installation (17’ Model)

- Figure 3-13: Hydraulic Installation (19’ - 27’ Models)

- Table 3-1: Hydraulic Hose Installation for 850/855 Series (19’ - 27’ Models)

- Figure 3-14: Hydraulic Installation (30’ - 35’ Models)

- Table 3-2: Hydraulic Hose Installation for 850/855 Series (30’ - 35’ Models)

- Figure 3-15: Hydraulic Installation (Lift) (41’ Model) (1 of 2)

- Figure 3-16: Hydraulic Installation (Fold) (41’ Model) (2 of 2)

- Table 3-3: Hydraulic Hose Installation for 850 Series (41’ Model)

- Figure 3-17: Shank, Clamp, and Sweep Assembly

- Shank Installation

- SMV Bracket Installation

- Disc Gang Installation, 850 Series

- Coulter Assembly, 855 Series

- Pull Hitch Installation

- Leveling Assembly Installation

- Optional Hydraulic Radius Rod

- Warning Lights Installation

- Rear Hitch Assembly (Option)

- Harrow Assembly Installation

- Operation and Maintenance

- Troubleshooting Guide