Choose the proper length lanyard for the job, How to size an ope connecting device – Klein Tools Occupational Protective Connecting Devices User Manual

Page 8

Note: Before choosing the proper length

connecting-device lanyard, you must determine the

distance between the work position and the

anchorage. This is true for all OPE system

applications, but accuracy is most important in fall-

arrest situations. (See “How to Size an OPE

Connecting Device”, on the next page.)

1.

In fall-arrest applications, OSHA requires that

the free-fall distance must never exceed 6' (1.8m).

OSHA also requires the maximum impact force for

an OPE harness be under 1800 lbs.

The major factor affecting the severity of the impact

force is the free-fall distance. Therefore, when

choosing connecting devices, it is important to select

the correct length in order to minimize the slack and

thus limit the free-fall distance and impact force in a

fall. When multiple connecting-device components

are used, you must consider the total slack for all

connecting devices. (For greater user control of

length, Klein offers adjustable-length rope and

webbing lanyards in addition to fixed-length rope

and webbing lanyards.)

Another factor that influences the impact force is the

elasticity of the lanyard. The greater the elasticity,

the less the impact force. Other factors affecting

impact force are the age and material of the lanyard

and the rigidity of the anchorage.

2.

In positioning applications, choose the correct

lanyard length to hold you at a comfortable distance

to perform the work.

3.

In suspension applications, choose the lanyard

length that will vertically position you at the correct

height to perform the work.

4.

In retrieval applications, choose the correct

lanyard length with minimum slack to allow your fast

removal in a potentially dangerous situation, while

not interfering with your ability to do the job.

Choose the Proper Length Lanyard for the Job

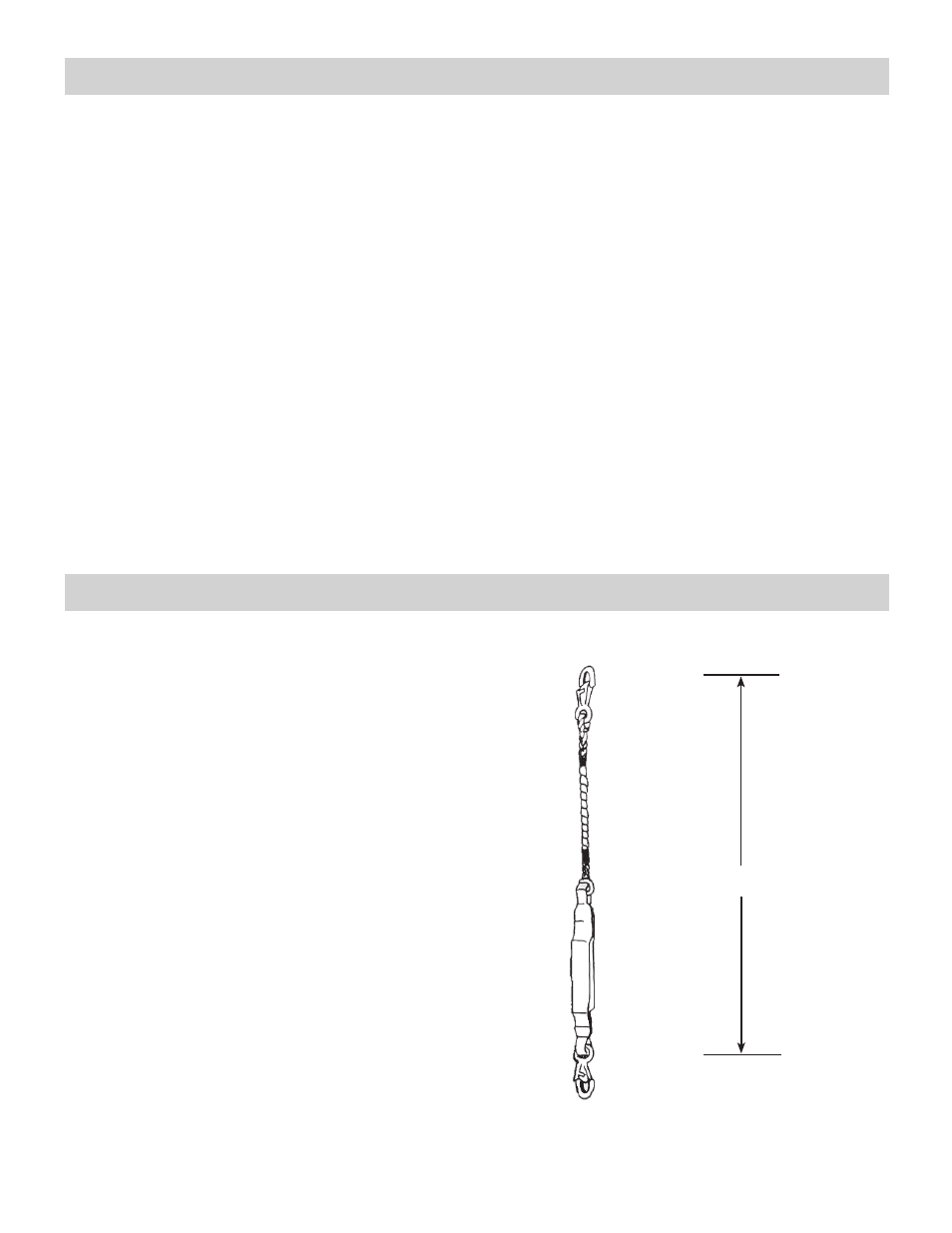

Connecting devices are measured from bearing

point to bearing point (see Figure A on this page).

The undeployed length (or range of lengths, if the

connecting device is adjustable) is clearly printed on

the warning tag or label. This is the undeployed

connecting device length.

The distance between the harness bearing point (the

fall-arrest D-ring) and the anchorage connector

bearing point (the anchorage connector D-ring) must

be determined before choosing the proper length

connecting device (see Figure B on the next page).

This is true for all OPE applications, but accuracy is

most important in fall-arrest systems.

Always rig connecting devices so that you avoid

contact with structures below in a fall. As a general

rule, allow an additional 3.5 feet (1 m) to each fall-

arrest connecting device to account for the following

connecting-device extension factors:

• elasticity (stretch) upon impact or load (rope

or web lanyards)

• extension upon impact (deceleration units or

deceleration lanyards)

How to Size an OPE Connecting Device

Length of undeployed

connecting device (Y)

(Continued on the next page)

Figure A