Connecting device inspection procedures – Klein Tools Occupational Protective Connecting Devices User Manual

Page 11

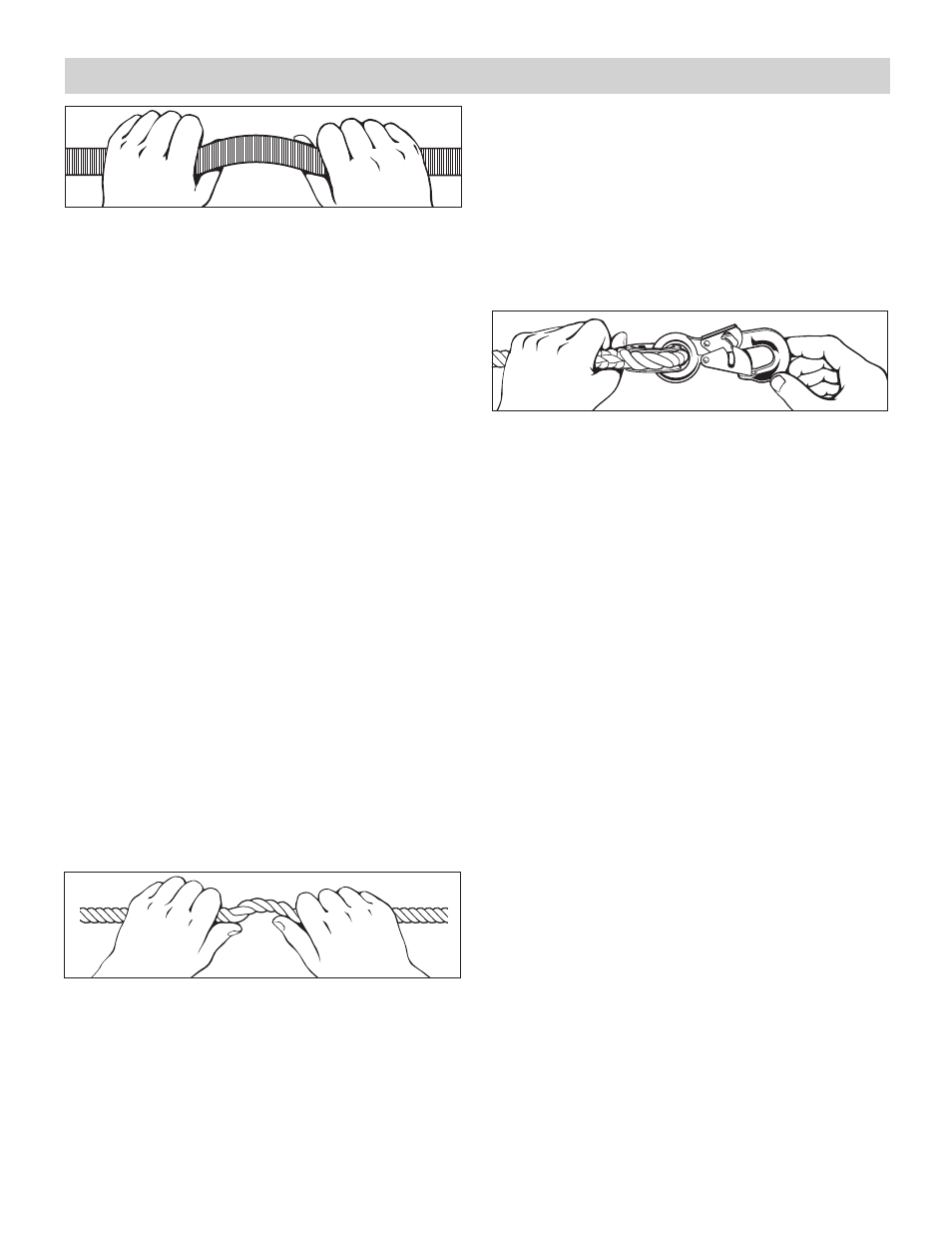

1.

Inspect stitching and webbing.

Check stitching for broken, burned, cut or pulled

stitches. Broken strands of webbing appear as tufts

on the webbing surface. To visually check for

damage caused by corrosives, heat, chemicals and

other conditions, hold the connecting device with

your hands six to eight inches apart. Bend the

webbing in an inverted “U” to cause surface tension

and to expose problem areas. Inspect entire length.

For deceleration units, check the stitching for

broken, burned, cut or pulled stitches, and the

breakaway jacket for cuts, tears, broken stitches,

stretch marks or other evidence of impact load.

Note: On Klein deceleration units, the uncovering

of a red-lettered warning label inside the leather

jacket indicates that the unit was subjected to a

severe impact force; therefore, the unit must not

be used and must be disposed of immediately.

For deceleration lanyards, check the stitching for

broken, burned, cut or pulled stitches, and/or other

evidence of impact load. Note: On Klein deceleration

lanyards, the uncovering of a red-lettered warning

label indicates that the unit was subjected to a

severe impact force; therefore, the unit must not

be used and must be disposed of immediately.

For aircraft-cable lanyards, check the full length

for breaks, burns, or cuts in the vinyl covering and

the aircraft cable.

2.

Check for broken strands.

Inspect rope lanyards for broken strands by twisting

the rope slightly to undo the braiding. Inspect entire

lanyard in this manner. Lanyards with broken strands

must be discarded.

Note: Twisted rope, such as the nylon filament and

polypropylene rope used in Klein lanyards, is subject

to a condition known as “hockling”, which is similar

to the reverse twisting often seen in a telephone

handset cord. This can be caused by a repetitive

twisting movement such as normal hand rotation in

hooking and unhooking a lanyard dangling freely, or

by using the lanyard to suspend equipment.

Preventative measures include: (1) never using a

lanyard for towing or hoisting, (2) inspecting and

smoothing out after each use, and (3) storing

neatly.

3.

Inspect snap hooks, D-rings, and other metal

parts.

Check hardware for sharp edges and cracks. Rollers

should not be distorted in shape and should roll

freely. Check all parts, especially corners and

attachment points, for wear and cracks.

4.

Destroy and replace all worn or damaged OPE

equipment.

If evidence of excessive wear, deterioration or

mechanical malfunction is observed, replace the

equipment immediately. Never work with worn or

damaged OPE equipment. Using damaged or

worn equipment can cause injury or death.

5.

The inspector is the most important part of

any inspection procedure.

Check all equipment thoroughly and follow all safety

procedures and guidelines. Do not take any shortcuts;

they could result in injury or death.

Important Note: OSHA specifies that all employers

covered by the Occupational Safety and Health

Act are responsible for inspection and

maintenance of all tools and equipment used by

employees — whether owned by the employees or

by the company. Personal-protective equipment

should be inspected before each use, and immediately

removed from service if any sign of wear or damage

is found.

T

I

Connecting Device Inspection Procedures