Customized linearization, User data, Math and logic module (extra code) – JUMO 701550 di 308 - Digital Indicator Data Sheet User Manual

Page 5: Binary functions, Functions of the outputs, Setup program for pc (accessory), Interfaces, Displays and controls, Dimensions side-by-side mounting

2012-05-30/00485042

Data Sheet 701550

JUMO GmbH & Co. KG • 36035 Fulda, Germany

Page 5/7

Customized

linearization

In addition to the linearizations for the usual

transducers, a customer-specific linearization

can be created. The programming is carried

out in the setup program, in the form of a table

of values (10 value pairs) or a formula

(coefficient entry of polynomial).

User data

Parameters which frequently have to be

changed by the user can be combined at the

user level, under “User data” (only through the

setup program).

Math and logic module

(extra code)

The math module makes it possible to

integrate measurements from the analog

inputs into a mathematical formula, so that

the calculated process variable is displayed.

The logic module can be used, for instance, to

make a logical combination of binary inputs

and limit comparator states.

Up to two math or logic formulae can be

entered through the setup program, and the

results of the calculations can be presented at

the outputs or via the display.

Binary functions

– key/level inhibit

– display off

– text display

– color changeover

– resetting MIN/MAX values

– “hold” function

– acknowledge limit comparators

– taring function

– resetting the taring function

– jump to next scroll parameter

The logic functions can be combined with one

another (only through the setup program).

Functions of the

outputs

– analog input variables

– math

– limit comparators

– binary inputs

– logic formula

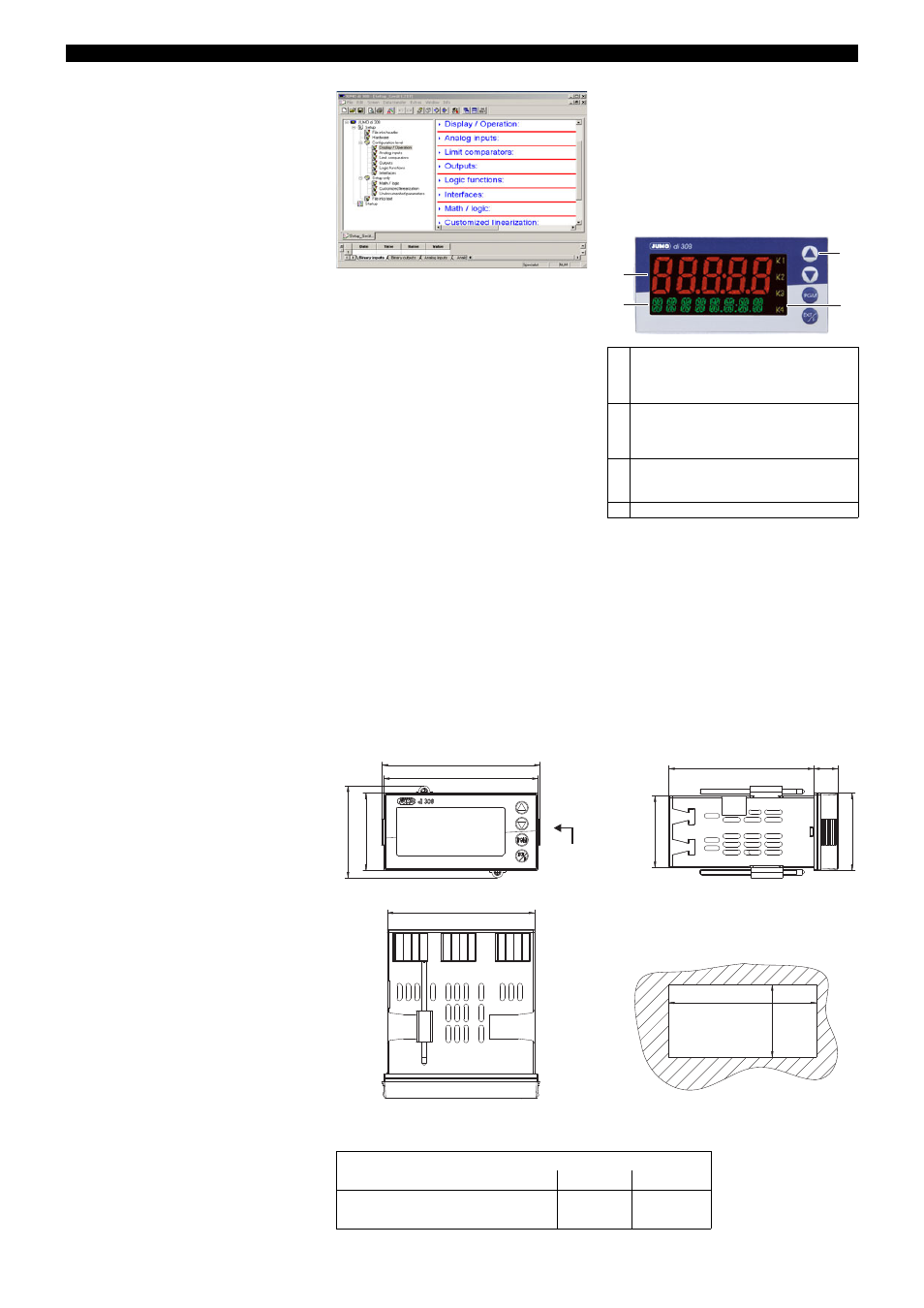

Setup program for PC

(accessory)

The PC setup program for configuring the

instrument is available in English, French,

German and other languages. It can be used

to create and edit data sets, transfer them to

the instrument or read them out from it. The

data can be saved and printed.

The program includes a startup function for

recording and visualizing measurement data.

Interfaces

Setup interface

The setup interface is integrated as standard

in the indicator. It can be used to configure the

instrument, in conjunction with the setup

program (accessory) and setup interface

(accessory).

RS422/RS485 interface

The serial interface serves for communication

with supervisory systems, using the Modbus

protocol.

PROFIBUS-DP

The indicator can be integrated into a field

bus system according to the PROFIBUS-DP

standard via the PROFIBUS-DP interface.

This PROFIBUS version is especially

designed for communication between

automation systems and decentralized

peripheral devices at the field level, and

optimized for speed.

Data transmission is made serially, using the

RS485 standard.

GSD generator, the project-planning tool that

is supplied with the package (GSD =

Gerätestammdaten, i.e. device data), is used

to make a selection of device characteristics

for the indicator, to create a standardized

GSD file that is used to integrate the indicator

into the field bus system.

Displays and

controls

(1)

7-segment display (measurement display)

5-digit, red; configurable decimal place

(automatic adjustment on

display overflow)

(2)

16-segment display (24-character running

text, parameter name, level symbols)

8-character, green or red;

configurable decimal place

(3)

Indication

yellow; for four switching states of max.

four outputs (indicator lit up = on)

(4)

Keys

(4)

(2)

(1)

(3)

Dimensions

Side-by-side mounting

Minimum spacing of panel cut-outs

horizontal

vertical

without setup plug:

30mm

11mm

with setup plug (see arrow):

65mm

11mm

57.1

96

99

48

44.5

92

+0.8

45

+0.8

15

48

90

91.5

PC

interface

adapter

Panel cut-out