INFICON TM-400 Thin Film Deposition Monitor User Manual

Page 44

4 - 10

IP

N 17

88

0

0 Re

v.

B

TM-350/400 Operating Manual

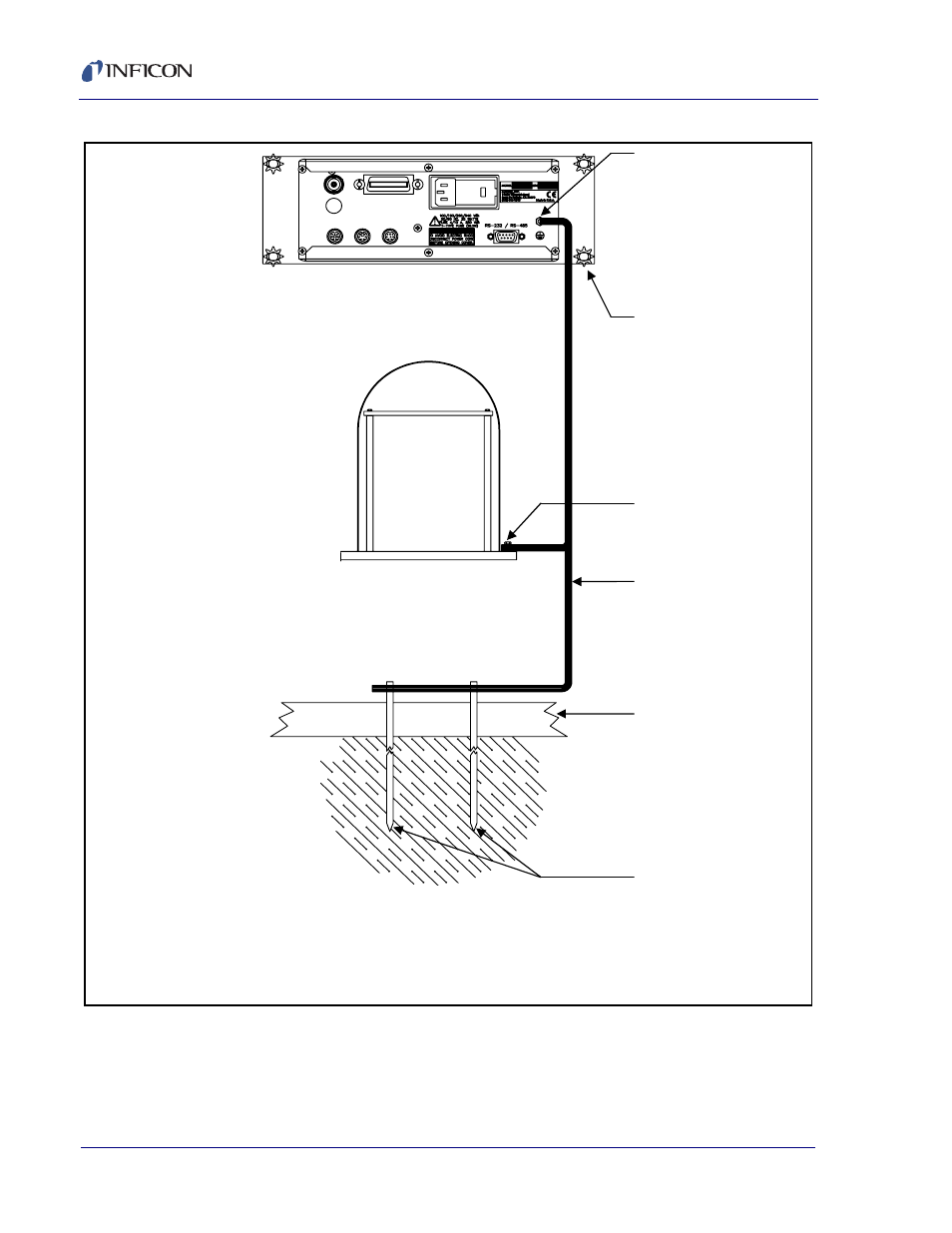

Figure 4-3 Recommended Grounding Method

Star Washers are

recommended to be use

in between the front panel

mounting angles and the

rack. The star washers

will cut through the paint

providing four additional

ground points between

the TM and the instrument

rack.

Bolt copper strap to the

ground lug of the TM

monitor.

System Grounding Point

Bolt copper straps to

clean, bare metal.

Copper Straps should be

as wide as practical,

preferably a 1” copper

sheet or a 1” braid.

Building Floor

Grounding Rods, 6 ft.

apart Copper-clad steel,

¾” dia. x 8 ft. (minimum)

1. As shown, sink two grounding

rods into the earth approximately

six feet apart. Locate these rods

as close as possible to the

vacuum cabinet.

2. Measure the resistance

between the rods. If the

resistance is greater than

3 Ohms, consult an Electrician

specializing in grounding

systems. If the resistance is

3 Ohms or less, connect a length

of copper grounding strap to the

system’s central grounding point,

which should be somewhere on

the vacuum system.

3. Silver solder the other end of

this grounding strap to the rods.

DO NOT rely on mechanical

connections.