Making loose tenon stock, Tips – INCRA Build-It STS Slot Mortiser User Manual

Page 4

INCRA Build-It STS Slot Mortiser Kit Manual

INCRA Build-It STS Slot Mortiser Kit Manual

Page 6

Page 7

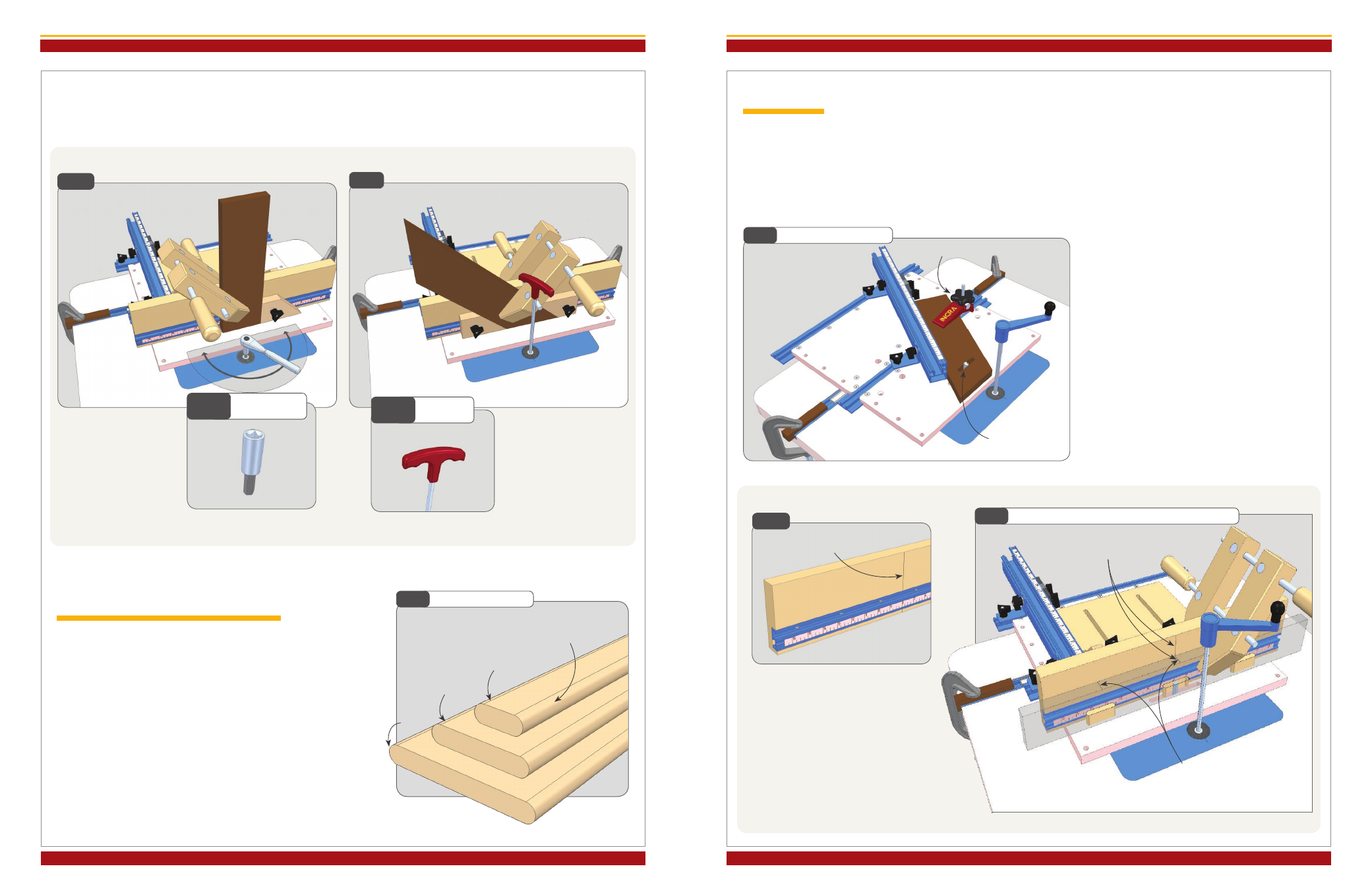

Vertically held stock will often interfere with full rotations of the

crank handle but your local hardware store has an easy solution.

Just purchase a hex driver for your ratchet set as shown and use

half rotations of the crank mechanism,

Figs. 20 & 20A. In many

cases, a T-handle hex key will work as well,

Fig. 21 & 21A.

To avoid interference

when cutting vertical

boards, use a ratchet

along with a hex driver

Making Loose Tenon Stock

Of course, slot mortises can be fun to cut with your new jig,

but you’ll need loose tenons to put it all together. When

preparing loose tenon stock, it’s a good idea to make several

sizes of long stock all at once then cut to length later as needed.

For instance, you can thickness plane material to match your

slot width then rip lengths of stock to 1”, 2” and 3” wide.

Roundover the edges with a bullnose bit that matches the slot

cutter’s diameter,

Fig. 22.

Fig.22

Loose Tenon Stock

3” Wide

2” Wide

1” Wide

Roundover edges with

bull nose bit

Faceplate stops can

be installed in a

variety of ways to

support your

workpiece

Fig.21

Fig.21A

T Handle

Hex Key

Tips

By removing the faceplate assembly and using the T-Track fence

along with one of the Build-It hold down clamps, you can cut

slot mortises and dados across the grain. And by angling the

fence across the Build-It platform you can angle the mortises

as well.

A stop positioner should always be clamped to the T-Track fence

at the left end of your material and a Build-It Clamp should be

used to prevent slippage during the cut,

Fig. 23. And again,

always start and stop each cut cycle with the jig against the

outfeed travel limit stop block.

Fig.23

Cross Grain Mortises

Fig.24

Fig.25

Cutting Mortise in the Middle of Long Stock

Need to cut a mortise in the middle of a longer

board? Just use a square to place a mark all the way

up the faceplate and in line with the 8” mark on the

faceplate scale,

Fig. 24.

(Remember the 8” mark will always be used as the

center of your slot length.) Now place a mark on

your board at the center of the desired slot

location.

The mark should be placed on the board edge

opposite where the mortise will be cut.

Align this mark with the faceplate mark when

clamping your material,

Fig. 25.

Through Mortise

Vertical mark on faceplate at 8”

Align marks when

clamping material

Mark center of slot

location on edge opposite where

slot is to be placed

Build-It Clamp

Fig.20

Fig.20A

A Hex Driver

for Ratchet