Bryant DURAPAC PLUS 551B User Manual

Page 21

—

21

—

VII. STEP 7 — ADJUST EVAPORATOR-FAN SPEED

Adjust evaporator-fan rpm to meet jobsite conditions.

For units with electric heat, required minimum cfm is 2250

for 551B090 and 102 and 3000 for 551B120 and 150. See

Table 8 for exceptions.

Table 8 — Minimum Required Airflow Exceptions

Tables 9 and 10 show fan rpm at motor pulley settings for

standard and high-static motors. Tables 11 and 12 show

evaporator-fan motor data. See Tables 13 and 14 and Fig. 36

for accessory and option static pressure drops. Refer to

Tables 15-28 to determine fan speed settings.

Fan motor pulleys are factory set for speed shown in Table 1.

To change fan speeds:

1. Shut off unit power supply and install lockout tag.

2. Loosen belt by loosening fan motor mounting nuts.

See Fig. 37 and 38.

3. Loosen movable pulley flange setscrew (see Fig. 39).

4. Screw movable flange toward fixed flange to increase

rpm or away from fixed flange to decrease rpm.

Increasing fan rpm increases load on motor. Do not

exceed maximum speed specified in Table 1.

5. Set movable flange at nearest keyway of pulley hub

and tighten setscrew. (See Table 1 for speed change

for each full turn of pulley flange.)

To align fan and motor pulleys:

1. Loosen fan pulley setscrews.

2. Slide fan pulley along fan shaft.

3. Make angular alignment by loosening motor from

mounting plate.

To adjust belt tension:

1. Loosen fan motor mounting nuts.

2. Size 090 — Slide motor mounting plate away from fan

scroll for proper belt tension (

1

/

2

-in. deflection with

8 to 10 lb of force) and tighten mounting nuts (see

Fig. 37).

Sizes 102-150 — Slide motor mounting plate down-

ward to tighten belt tension. Secure motor mounting

plate nuts. See Fig. 38. Use

1

/

2

-in. deflection with 10 lb of

force.

3. Adjust bolt and nut on mounting plate to secure

motor in fixed position.

UNIT

551B

UNIT

VOLTAGE

HEATER

kW

UNIT

CONFIG-

URATION

REQUIRED

MINIMUM

CFM

120,150

208/230

42.4

Horizontal

3200

208/230

50.0

Horizontal

3200

460

50.0

Horizontal

or Vertical

3200

090-150

575

17.0

Horizontal

or Vertical

2800

34.0

2350

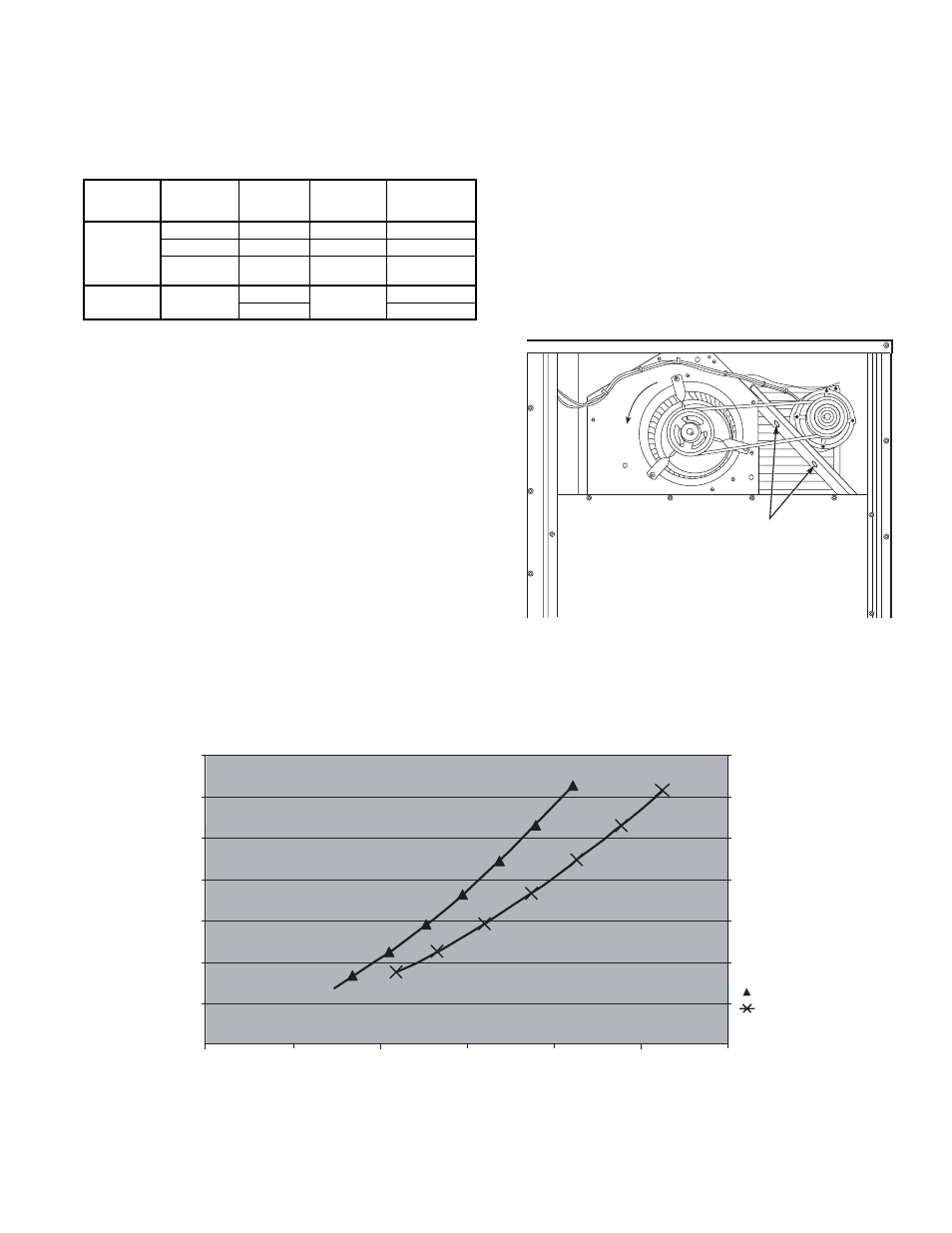

Fig. 37 — Typical Belt-Drive Motor Mounting for

Size 090

MOTOR MOUNTING

PLATE NUTS

6000

5000

4000

3000

2000

1000

0

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

DEL

T

A

P

IN. WG

7.5 ton

8.5, 10 & 12.5 ton

CFM

Fig. 36 — Perfect Humidity™ Dehumidification System Static Pressure Drop (in. wg)