Run time (min.) – Flint & Walling Constant Pressure Pumping Stations - ADW2W73 User Manual

Page 6

6

(FW1365)

95 North Oak St. • Kendallville, IN 46755 • 1-800-345-9422

tABle 4 SySteM trOuBleShOOtInG GuIDe

Symptom

Possible Cause

Corrective Action

Water flow rate

is not as high as

expected.

Motor/Pump is running backwards.

Reverse connection of motor cable wires at connection

point U & V.

Pump capacity cannot supply the demand.

Use pump with higher flow rating (if head requirement is

still satisfied).

Temperature in the controller is too high. If

the controller’s heat exchanger becomes too

hot, the controller will reduce the switching

frequency to the motor to lower the power

consumption.

Make sure there is at least 4 inches of room around the

controller for movement of air. Avoid direct sunlight.

Reduce ambient temperature below 104°F (40°C). Increase

input voltage if below 230 VAC.

Disconnected or broken wire feeding motor. Check motor, motor wiring and splices. Make certain all

connections are tight.

Excessive

pressure

fluctuations.

Waterlogged tank.

Check tank for bladder damage. Replace if necessary.

Reset the tank pre-charge pressure (should be 70% of

pressure sensor setting).

Pressure tank is too small for flow rating of

the pump.

Use larger tank (refer to Table 3 on Page 4 for minimum

Pressure Tank size).

Motor runs

continuously

with no flow

demand.

Leak in the household or outdoor plumbing. Check for leaky faucets, valves and/or pipe fittings and

repair.

Leak in the pitless adapter.

Re-seat the pitless adapter. Replace seal as needed.

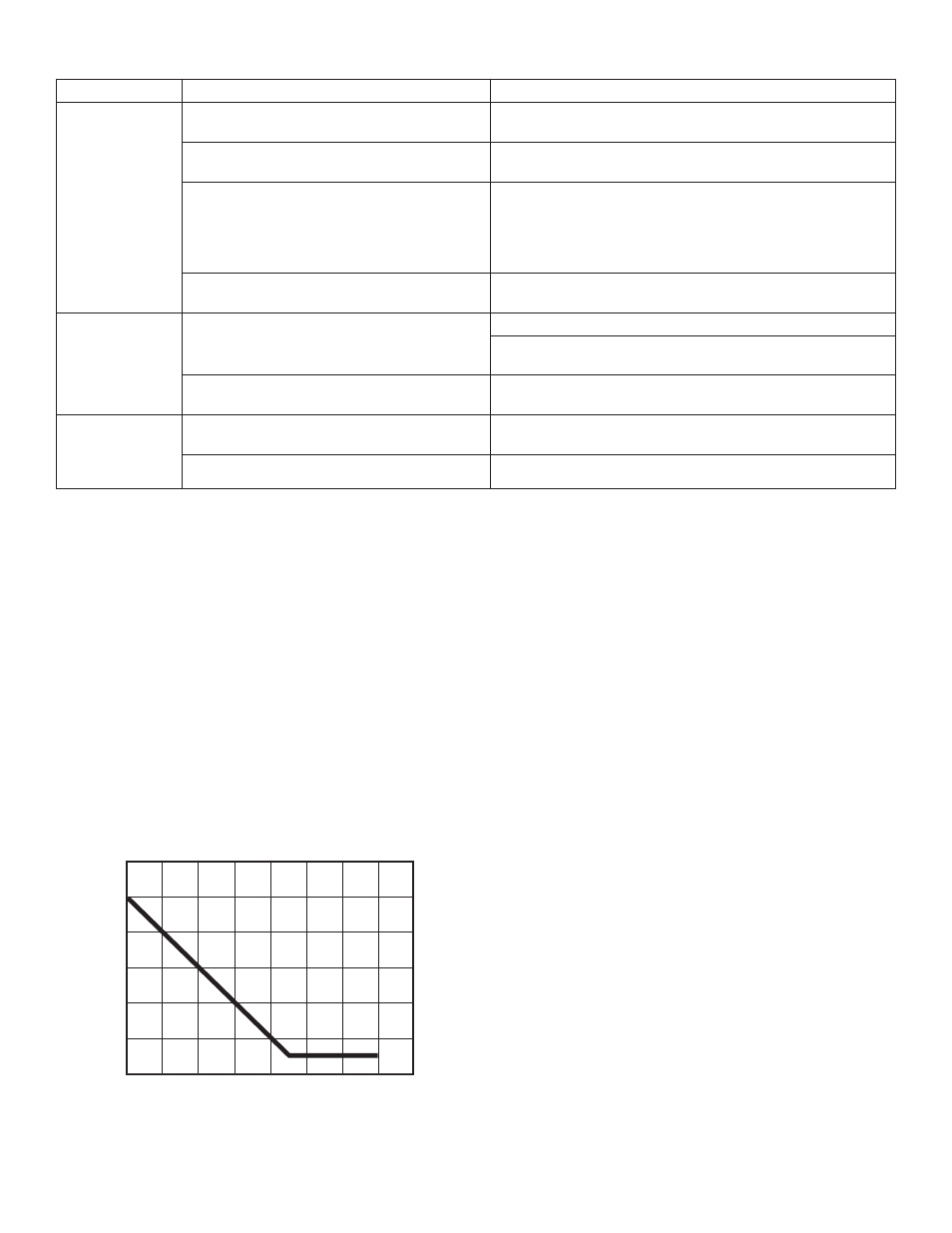

unDerlOAD IntellIGent reSet

(Display showing )

If a motor Underload fault condition occurs, the most likely

cause is an overpumped well (dry well) or loss of incoming

feed water to the pump. In a dry well situation to allow the

well to recover, the Artesian Drive controller will wait 30

seconds to 5 minutes, determined by the amount of time

the motor had been running before sensing the underload,

before restarting the motor. For example, the first time the

fault occurs and the pump has been running 6 minutes, the

controller stops the motor and will wait 30 seconds before

attempting to restart the pump. If the system would then run

for 2 minutes and an underload fault recurs, the controller

will wait 3 minutes before attempting to restart the pump.

This schedule allows for the minimum off-time possible based

on the recovery time of the well or water feed supply.

If there is an obstruction (such as a closed valve) between the

pump and the pressure sensor, the controller will also sense

an underload is this “dead head” condition stopping the

motor to avoid damaging the pump.

0 1 2 3 4 5 6 7 8

6.0

5.0

4.0

3.0

2.0

1.0

0.0

Run Time (Min.)

Off

Time (Min.)

IL0750

figure 12

Over-teMPerAture

The Artesian Drive controller is designed for full power

operation in ambient temperatures up to 104°F (40°C)

as long as the input voltage is kept at 230 VAC. Under

extreme thermal conditions, the controller will reduce the

switching frequency in an attempt to avoid shutdown. If the

temperature of the controller is still too hot the controller will

shut itself off to avoid causing damage to itself. Full pump

output is restored when the controller temperature cools to a

safe level.

NOTE: The Artesian Drives are factory programmed to

F&W pumps to provide optimum performance and motor

protection. The Artesian Drive can be used with other

pumps, but the maximum motor amperage needs to be

compared to the factory programmed current value (refer

to the Specifications section under the appropriate model).

If the maximum motor current varies more than 5% from

the programmed value, the motor current value in the drive

needs to be changed for motor protection and optimum

performance. For details on how to change this value in the

drive, please contact Technical Support at 1-800-345-9422.