Flint & Walling Constant Pressure Pumping Stations - ADW2W73 User Manual

Page 5

5

(FW1365)

95 North Oak St. • Kendallville, IN 46755 • 1-800-345-9422

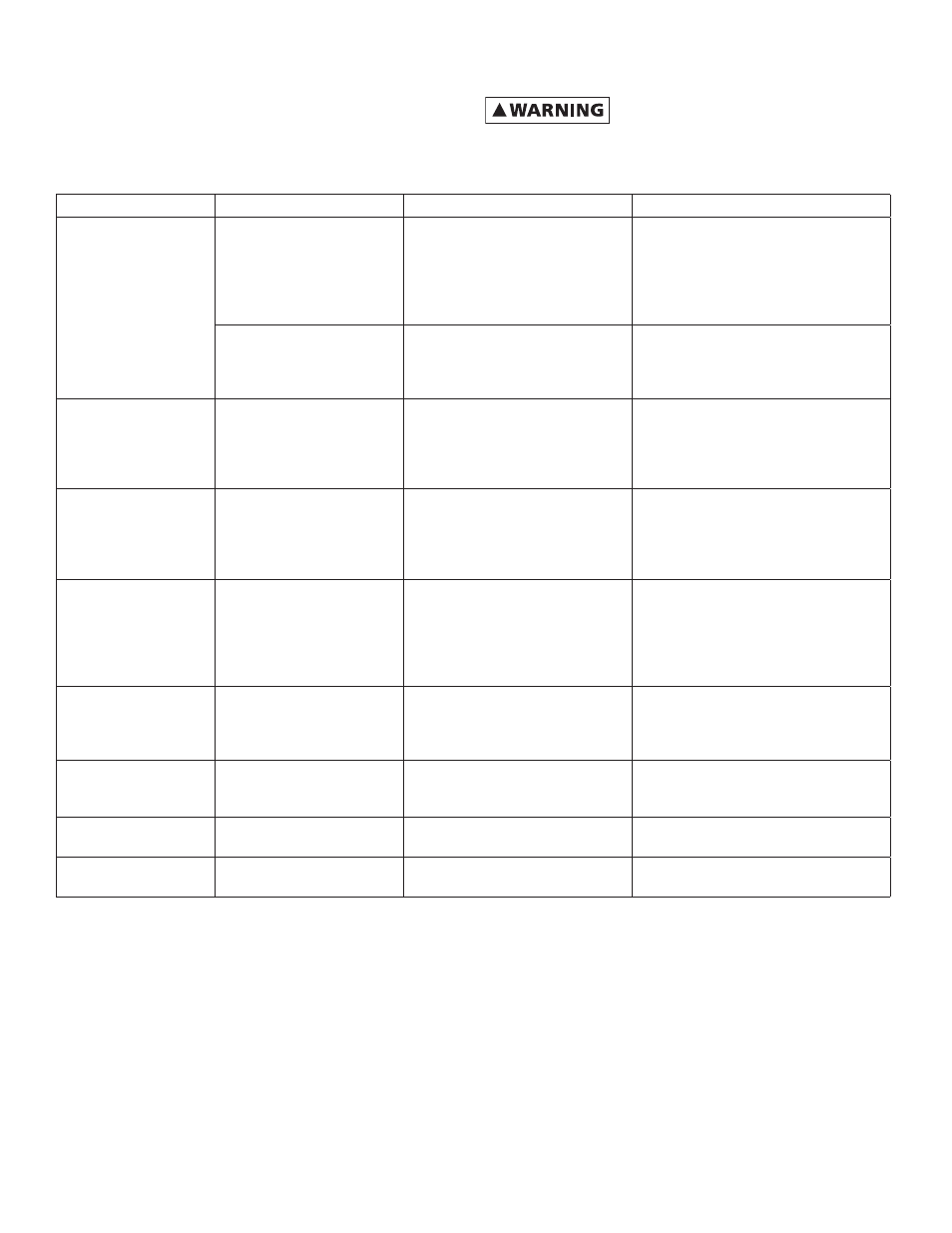

tABle 3: DIAGnOStIc fAult cODeS

DISPlAy cODe

fAult

POSSIBle cAuSe

cOrrectIve ActIOn

Motor Underload

Air-locked pump. Overpumped

or dry well. Worn pump.

Damaged shaft or coupling.

Pump deadhead. Blocked pump

or screen.

Wait for well to recover and

automatic restart timer to time out.

If the problem does not correct,

check motor and pump. See

description of “Intelligent Reset” on

Page 18.

Water Over Temp

Pump running deadhead

because of transducer failure or

clogging of transducer pressure

point

Clean out pressure port of transducer

or replace transducer.

Undervoltage

Low line voltage. Misconnected

input leads.

Check for loose connections. Check

line voltage. Report low voltage

to the power company. Unit will

start automatically when the proper

power is supplied.

.

Short Circuit

When fault is indicated

immediately after power-

up, short circuit due to loose

connection, defective cable,

splice or motor.

Check motor wiring. Turn power off

till display darkens then apply power

again to reset.

.

Over Current

When fault is indicated while

motor is running, over current

due to loose debris trapped

in pump, or water demand

is exceeding pump & motor’s

capability.

Check pump.

.

(Number other than

0.0 & motor is not

running)

Open Circuit

Loose connection. Defective

motor or cable.

With power off, check motor, motor

wiring and splices. Make certain all

connections are tight. Apply power

again to reset.

. .

Overheated Controller

High ambient temperature.

Direct sunlight. Obstruction of

air-flow.

This fault automatically resets when

the temperature returns to a safe

level.

.

Controller Stopped

Loose jumper wire

Re-insert jumper wire into control

terminals B2 & B4.

c

Loss of Transducer Signal

Unconnected or failed

transducer

Reconnect or replace transducer

DIAGnOStIc fAult cODeS

Should an application or system problem occur, built-in

diagnostics will protect the system. The display will change

to indicate the nature of the fault. In some cases, the system

will shut itself off until corrective action has been taken. Fault

codes and the recommended corrective action for each are

listed in the following chart.

!

Do not attempt to carry out internal

repairs. Return a faulty drive to the

supplier for repair.