Flint & Walling Constant Pressure Pumping Stations - ADW2W73 User Manual

Page 4

4

(FW1365)

95 North Oak St. • Kendallville, IN 46755 • 1-800-345-9422

!

Serious or fatal electrical shock may result

from failure to connect the motor, the Artesian Drive, metal

plumbing and all other metal near the motor, or cable to the

power supply ground terminal, using wire no smaller than

motor cable wires. To reduce risk of electrical shock, disconnect

power before working on or around the water system.

StArt-uP PrOceDureS

Proper operation of the pump station requires that operators

do not deviate from these procedures. Deviation from these

procedures can result in serious/fatal injury to personnel and/

or damage to the Pump Station.

Caution: Never hang or store items on

pump station piping or components.

1. Open any user installed value on the intake side of the pump

and verify that the isolation value is closed if installed on the

discharge side of the system

2. Verify that the pump is primed. For gravity fed systems, this

can be accomplished by opening hose bib valve installed on

the system manifold to allow the water pressure to push out

the air from the pump. For suction lift systems, fill the pump

and intake piping with external water source until water

begins coming out the open hose bib valve.

3. Close hose bib valve.

4. Supply electrical power to Pump Station by truing on the

user installed disconnect to the ON position and allow system

to pressurize and check for leaks on plumbing installed.

5. Once pressure has been established, partially crack open the

station isolation valve (while maintaining pressure) and open

valves farthest away from pump station to bleed air out of

the system & piping

6. When the whole Main Line has been bled of air, fully open

the discharge isolation valve.

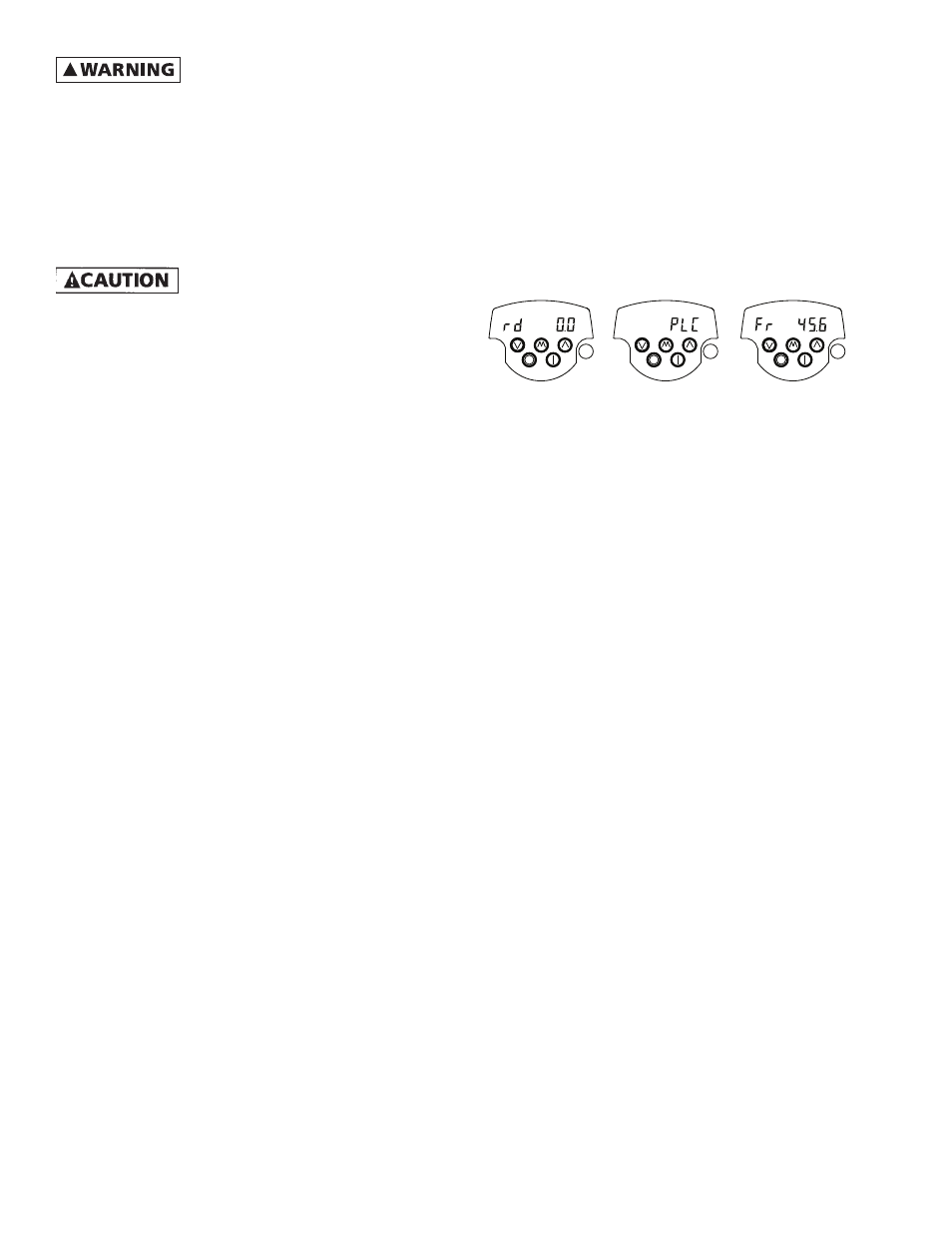

7. As long as the display is lit up the system has power. When

the display shows . or flashes PLC as shown, the system

is active, but the pump is not running. The display will show

. as shown (where the numbers may be fluctuating)

when the pump is running.

IL0748

figure 2

hOW tO ADJuSt SySteM PreSSure SetPOInt

Press and release M button to display flashing number on left

hand side of display (i.e. 01).

Using ↑ and ↓ buttons, scroll until you reach 10 flashing on

left hand side.

Press and releae M button and then press & release ↑ button

to scroll display to show L3 on right hand side.

Press and release M button and use ↑ and ↓ to scroll until you

reach 61 flashing on left hand side.

Press and release M button and CodE flashes on the right

hand side.

Press & release ↑ until Co 3 is displayed.

Press & release M button to make the 0 of 50 begin flashing.

Using ↑ and ↓, scroll the value to the pressure set point in PSI

desired. The pressure rating has a maximum value of 100 PSI.

Press and release M button to return to having 61 on left of

screen flashing.

Using ↑ and ↓ buttons, scroll to 10 flashing on left hand side.

Press & release M button, then press & release ↑ button until

LoC id displayed.

Press & release M button twice to return to standard screen.