Wiring connections – Flint & Walling Constant Pressure Pumping Stations - ADW2W73 User Manual

Page 3

3

(FW1365)

95 North Oak St. • Kendallville, IN 46755 • 1-800-345-9422

3. The Pump Station shall be lifted with proper lifting

equipment (i.e. fork lift). Be sure all necessary lifting

equipment is used properly.

4. DO NOT ATTEMPT TO USE DRIVE SUPPORT BRACKET FOR

LIFTING THE PUMP STATION. The bracket will not support

the overall weight of the pump station.

5. The pump station must be installed according NEC and

local electrical codes. Proper electrical disconnect MUST be

installed in view of the pump station.

6. Ensure compliance with all applicable local, state, and

OSHA regulations when installing, operating, repairing, or

maintaining the pump station.

7. The pump station is manufactured to best ensure operator

safety under normal operating conditions. The manufacturer

will not take any responsibility for personal or equipment

damage if the equipment has been modified or if the

safeguards have been modified. Any proposed modifications

must be carefully documented (to include a risk analysis) by

the party proposing the modification; and coordinated with

and approved by the manufacturer. Otherwise, the customer

assumes all responsibility for its actions and subsequent

consequences.

InStAllAtIOn PrOceDure

1. Position the skid in final location and attach to pad as

necessary. NOTE: For serviceability of the pump and

protection of discharge plumbing fixtures down line of the

pump station, it is recommended to incorporate unions and

isolation valves on the intake and discharge plumbing. If

deemed applicable, a bi-pass loop with properly placed

valves should also be incorporated into the installation.

2. Install plumbing to the intake of the pump. Note: For

proper functionality of the system it is not recommended

that a pipe size smaller than 2-1/2” is use on the intake of

the pump. Note: For suction lift applications, intake pipe

plumbing needs to allow for suction pipe to be filled by

external water source to prime the pump. Note: If the water

source for the pump station is susceptible to containing

debris, an appropriately sized filter should be installed prior

to the pump intake which should be checked & cleaned

regularly to avoid clogging the pump and/or degrade system

performance.

3. Install plumbing to discharge manifold. Note: For proper

functionality of the system it is not recommended that a pipe

size smaller than 2” is use on the discharge manifold. Note:

To avoid causing damage to the system, when tightening

onto the threads of the discharge manifold, a pipe wrench

should be used on the manifold to keep the manifold from

turning.

4. With supply power OFF, connect power supply cables to L1

& L3 terminals for single phase power supplied drives or L1,

L2 & L3 terminals for three phase supplied drives. Attach

ground wire to grounding lug on drive. See Figures 4 - 6 on

page 7 & 8 for depictions of each HP power supply wiring

connections.

!

3 & 5 HP Models: To avoid a fire hazard and

maintain validity of the UL listing, torque the power terminal

screws to 12 lb.-in. (1.4 N-m).

!

7.5 HP 3 Phase Model: To avoid a fire hazard

and maintain validity of the UL listing, torque the power

terminal screws to 13.2 lb.-in. (1.5 N-m).

!

7.5 HP 1 Phase Model: To avoid a fire hazard

and maintain validity of the UL listing, torque the power

terminal screws to 21.6 lb.-in. (2.5 N-M).

Wiring connections

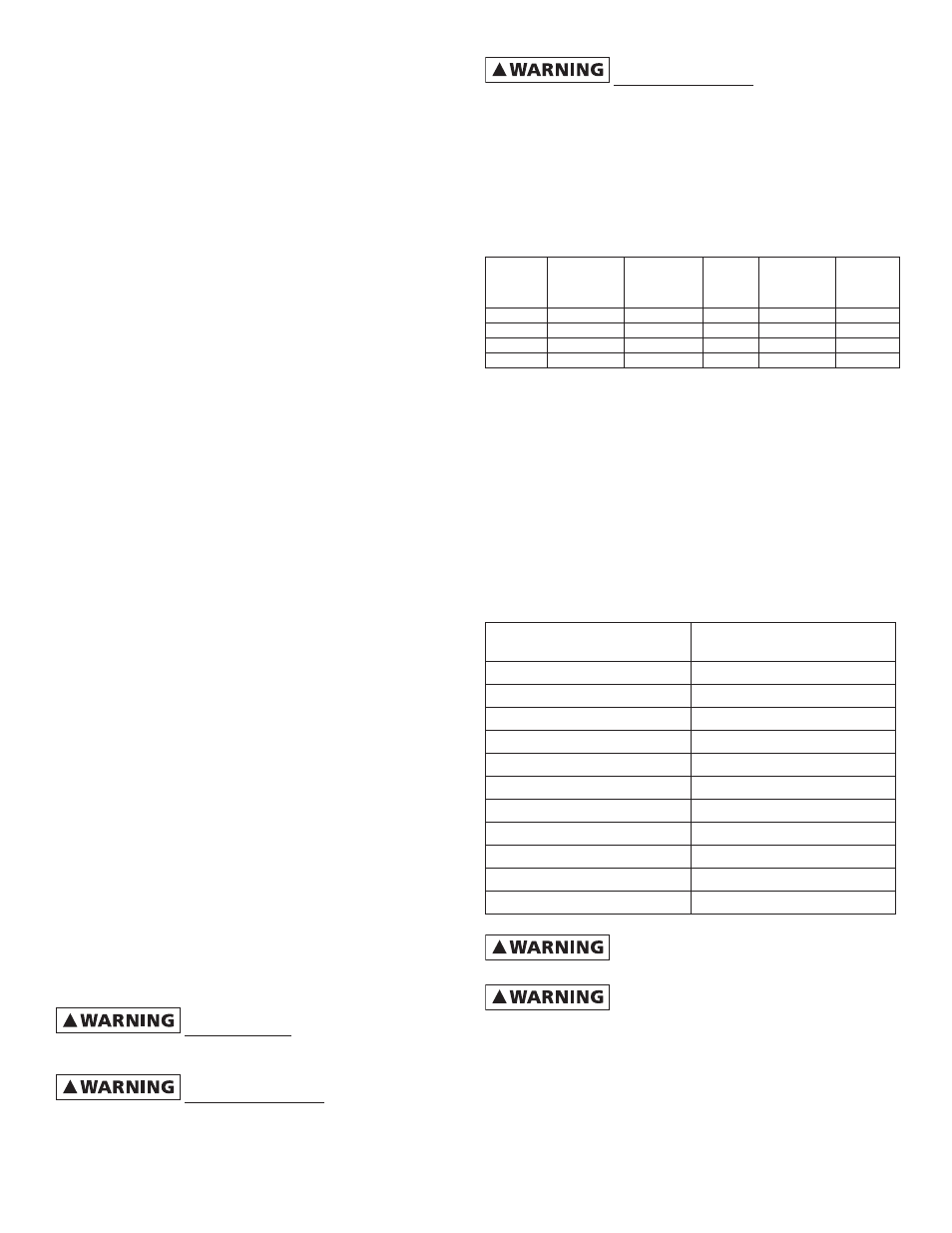

cIrcuIt BreAKer AnD WIre SIzInG

The minimum circuit breaker size and maximum allowable

wire lengths for connection of motor to the Artesian Drive

are given in the following table:

tABle 1: MInIMuM BreAKer SIze AnD MAxIMuM

cABle lenGth (In feet)

Drive

Model

Recommended

Input Cable

Recommended

Motor Cable

Maximum

Cable

Length to

Motor (Ft.)

Recommended

Breaker

Maximum

Continuous

Current

ADW2W31

10

14

325

30

9.6

ADW2W51

8

12

325

30

15.0

ADW2W71

6

10

325

50

22.0

ADW2W73

8

10

325

30

22.0

NOTE:

•

Maximum allowable wire lengths are measured between

the controller and motor.

•

Aluminum wires should not be used with the Artesian

Drive.

•

Wire sizing between the service entrance and the

controller must be sufficient to provide the required

maximum input amps to the controller while conforming

to local standards and codes.

The pressure tank pre-charge setting should be 70% of the

system pressure sensor setting as indicated in the following

table.

tABle 2: PreSSure tAnK AIr PrechArGe (PSI)

System Pressure (at Pressure

Sensor)

Pressure Tank Precharge

Setting (± 2 PSI)

30

21

35

25

40

28

45

32

50

35

55

39

60

42

65

46

70

49

75

53

80*

56

!

Do not use motor or system in swimming

areas.

!

Because of the leakage current produced

by the internal filtering, permanent fixed ground connections

must be made using two independent conductors each with

a cross-section equal to or exceeding that of the supply

conductors. The drive is provided with two ground terminals

marked PE to facilitate this for 3 & 5 HP models.

NOTE: Ensure that the system is properly grounded all the

way to the service entrance panel. Improper grounding may

result in the loss of voltage surge protection and interference

filtering.