3 installation, electric, 4 installation of accessories, 6 commissioning – Festo DGC-K-18 … -80 User Manual

Page 3: 1 commissioning the complete system, 2 preparing for commissioning, 3 carrying out commissioning

5.3 Installation, electric

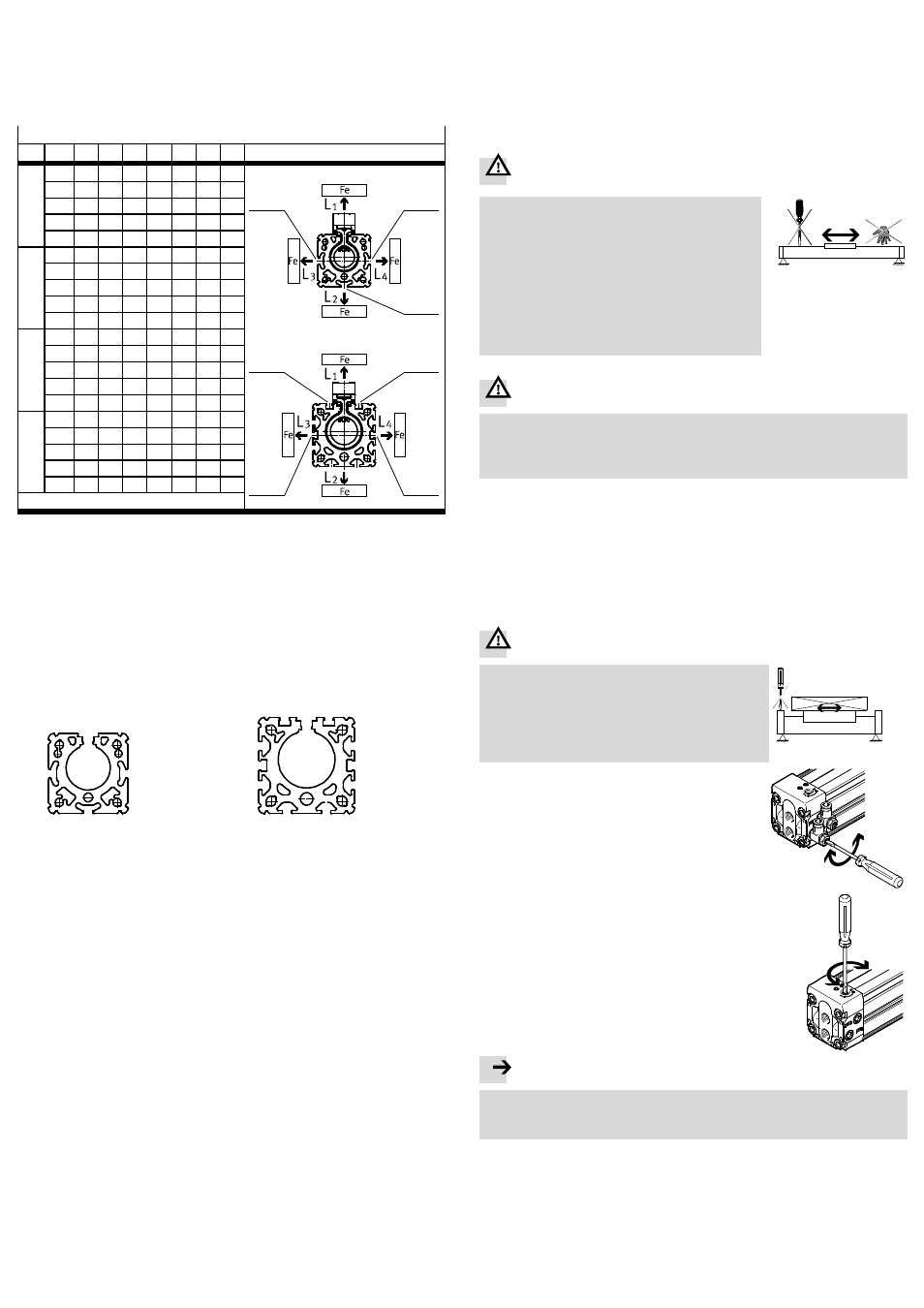

Position scanning with proximity sensors SME/SMT:

• Use grooves (S) for mounting the proximity sensors (

Fig. 12).

• Observe the minimum distances between ferritic loads and the proximity

sensors.

In this way you will avoid incorrect switching as a result of external influences.

Minimum clearances [mm]

POS 18 25 32 40 50 63 80

L1

1

0

0

0

0

0

0

0

2

1

3

DGC-K-18/-25

4

5

DGC-K-32 ... -80

2

1

2

0

0

0

0

0

0

0

3

0

0

–

–

–

–

–

4

–

–

10

30

10

20

10

5

–

–

10

30

10

20

10

L2

1

10

0

0

0

0

0

0

2

10

0

0

0

0

0

0

3

30

10

–

–

–

–

–

4

–

–

0

0

0

0

0

5

–

–

0

0

0

0

0

L3

1

30

10

10

30

10

20

10

2

0

0

0

0

0

0

0

3

10

0

–

–

–

–

–

4

–

–

0

0

0

0

0

5

–

–

0

0

0

0

0

L4

1

0

0

0

0

0

0

0

2

30

10

10

30

10

20

10

3

10

0

–

–

–

–

–

4

–

–

0

0

0

0

0

5

–

–

0

0

0

0

0

Fig. 11 (POS = position of proximity switch)

Laying the cables for the proximity switches:

• Observe that the cables for the proximity switches can be guided through the

groove.

5.4 Installation of accessories

• Use the following grooves for attachment of the accessories (

Fig. 12).

S = Slot for proximity sensor

N = Slot for mounting accessories

DGC-K-18/-25

DGC-K-32 ... -80

S/N

S/N

S/N

S

S

N

N

N

N

S

S

N

N

Fig. 12

• Use the slot covers (

www.festo.com/catalogue):

– to prevent contamination in the slots (S)

– for locking the cables of proximity switches.

6

Commissioning

6.1 Commissioning the complete system

• Slowly pressurise the system as a whole.

In this way you will prevent sudden uncontrolled movements.

For slow start-up pressurisation, use start-up valve type HEL.

6.2 Preparing for commissioning

Before each commissioning and in operation:

Warning

Fast moving parts can cause injury to people in the

environment of the DGC-K.

• Make sure that, in the travel range

– Nobody can reach into the path of the movable

components (e.g. by providing a protective

guard)

– There are no foreign objects in the path of the

moving components.

It should not be possible to touch the DGC-K until

the load has come to complete rest.

Fig. 13

Warning

Without external cushioning devices the DGC-K may be damaged if the maximum

values specified in the catalogue are exceeded.

• Make sure that the limit values are not exceeded even in the event of malfunc-

tions.

At medium or large useful loads or high speeds:

• Use the configuration tool “DGC-QuickCalc” for pneumatic drives in the support

portal (

www.festo.com/sp).

• Make sure that cushioning devices are of sufficient size.

Without external cushioning devices the DGC-K will withstand maximum speeds

and useful loads as per catalogue specifications or table (

Fig. 18).

6.3 Carrying out commissioning

Warning

Risk of collision!

• Note that, for the load geometries with projection,

the regulating screws

2 of the DGC-K may only be

turned when the slide is at rest.

Fig. 14

1. Close the one-way flow control valves

– for both sides at first completely

– then one rotation open again.

Fig. 15

Using the internal end position cushioning PPV:

2. Close the adjusting screws for the internal end pos-

ition cushioning PPV

2

– on both sides at first completely

– then one rotation open again.

Fig. 16

Note

To set the end position cushioning:

• Make sure that the slide reaches the end positions without striking hard

against them or bouncing back.

3. Pressurize the DGC-K slowly as follows:

– at first on both sides simultaneously. The slide will then move slightly to a

centre of equilibrium.

– Then exhaust the DGC-K on one side.

In this way you can avoid peak loadings on the DGC-K and in the compressed

air network.

4. Start a test run.

5. Check whether the speed must be modified (

5.2 Installation, pneumatic).