2 installation, pneumatic – Festo DGC-K-18 … -80 User Manual

Page 2

DGC-K-18

DGC-K-25

DGC-K-32

DGC-K-40

DGC-K-50

DGC-K-63

DGC-K-80

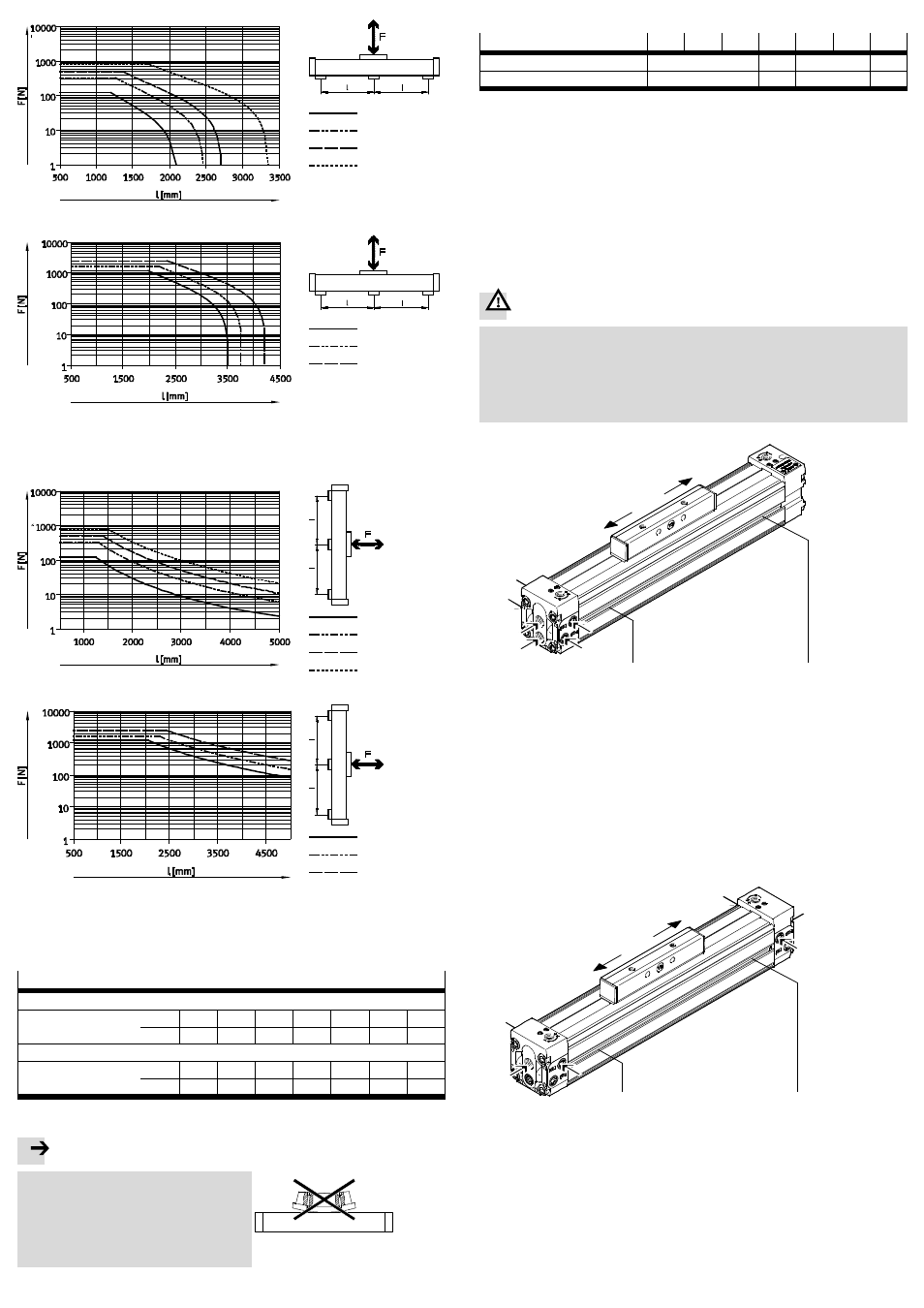

Fig. 4

Required support spacing (l) with horizontal mounting orientation

DGC-K-18

DGC-K-25

DGC-K-32

DGC-K-40

DGC-K-50

DGC-K-63

DGC-K-80

Fig. 5

Required support spacing (l) with horizontal mounting orientation

• Note the tightening torques when attaching.

Tightening torques of the mounting screws

Direct mounting on thread

9

Size

18

25

32

40

50

63

80

[Nm]

2.5

3

4

5

8

14

45

Slot attachments (e.g. with MUP central support)

Size

18

25

32

40

50

63

80

[Nm]

3

3

4.5

5.5

18

18

18

Fig. 6

Note

With hard and stiff useful loads:

If the slide

3 is bent due to a buckled use-

ful load, it will reduce the service life of the

drive.

• Make sure the mounting surface of the

useful load is even.

Fig. 7

• Observe the tightening torques for the threads

4 in the slide.

Size

18

25

32

40

50

63

80

Thread

M5

M6

M8

M12

Tightening torques

[Nm]

3.5

6

12

30

Fig. 8

Effective loads with own guide:

• Adjust the guides of the effective load and of the DGC-K so that they are exactly

parallel.

In this way can you avoid overloading on the slide (Permissible forces

11 Technical data).

The driver DARD-L1 offers a torque-free and almost backlash-free power trans-

mission (

www.festo.com/catalogue).

5.2 Installation, pneumatic

For installation in a vertical or inclined position:

Warning

If there is a pressure drop, the movable load will drop down:

Danger of crushing!

• Check whether HGL non-return valves are necessary.

In this way, you can prevent the movable load from sliding down suddenly.

• Check whether safety measures are required to prevent sinking as a result of

leakage (e.g. toothed latches or moveable bolts).

A(2)

A(1)

A(2)

W(2)

1

2

A(1)

W(1)

1

2

W = compressed air supply ports from

the plant

1 = end position on the connection

side

1 = movement to the connection side

A = alternative connections

2 = end position connection side

2 = movement to the connection side

Fig. 9

• Select the suitable compressed air supply ports.

In addition to the supply ports provided at the factory (W), there are also the

alternative ports (A). These are fitted with plug screws.

For the linear actuator DGC-K of variant D2, the compressed air supply can be

made on both sides.

A(1)

W(1)

A(2)

A(2)

W(2)

1

2

A(1)

1

2

W = compressed air supply ports from

the plant

1 = end position on the connection

side (left)

1 = movement to the connection

side (left)

A = alternative connections

2 = end position connection

side (right)

2 = movement to the connection

side (right)

Fig. 10

For setting the speed:

• Rotate the one-way flow control valves GRLA into the supply ports.