Enerpac PR-Series Air User Manual

Page 7

7

Table 7 - U-Ring Information

Jack Model

U-Ring Size and Model Number

U-Ring

Set Model

Number

Items Included in Each U-Ring Set

1 inch

[25 mm]

3 inch

[76 mm]

4-1/2 inch

[114 mm]

5-1/2 inch

[140 mm]

10 inch

[254 mm]

2x

1x

2x

1x

PRAMA06014L

PRU11

PRU13

PRU14

-

PRU110

PRUS126

PRU11

PRU13

PRU14

-

PRAMA06027L

PRU11

PRU13

PRU14

-

PRU110

PRUS137

PRU11

PRU13

PRU14

PRU110

PRAMA10016L

PRU11

PRU13

PRU14

-

PRU110

PRUS126

PRU11

PRU13

PRU14

-

PRAMA10027L

PRU11

PRU13

PRU14

-

PRU110

PRUS137

PRU11

PRU13

PRU14

PRU110

PRASA10016L

PRU11

PRU13

PRU14

-

PRU110

PRUS126

PRU11

PRU13

PRU14

-

PRASA10027L

PRU11

PRU13

PRU14

-

PRU110

PRUS137

PRU11

PRU13

PRU14

PRU110

PRASA15016L

PRU151

PRU153

-

PRU155

PRU1510

PRUS1526

PRU151

PRU153

PRU155

-

PRASA15027L

PRU151

PRU153

-

PRU155

PRU1510

PRUS1537

PRU151

PRU1510

PRU155

-

PRASA20016L

PRU201

PRU203

-

PRU155

PRU1510

PRUS2026

PRU201

PRU203

PRU205

-

PRASA20027L

PRU201

PRU203

-

PRU155

PRU1510

PRUS2037

PRU201

PRU2010

PRU205

-

5. Slowly lower the cylinder rod until the weight of the load

is supported by the U-Rings. Refer to the information in

Section 5.3 for jack operating instructions.

IMPORTANT: Follow all applicable work rules and regulations

in eff ect at your facility or worksite. The use of auxiliary stands,

blocking or other additional load supports may be required even

when U-Rings are installed.

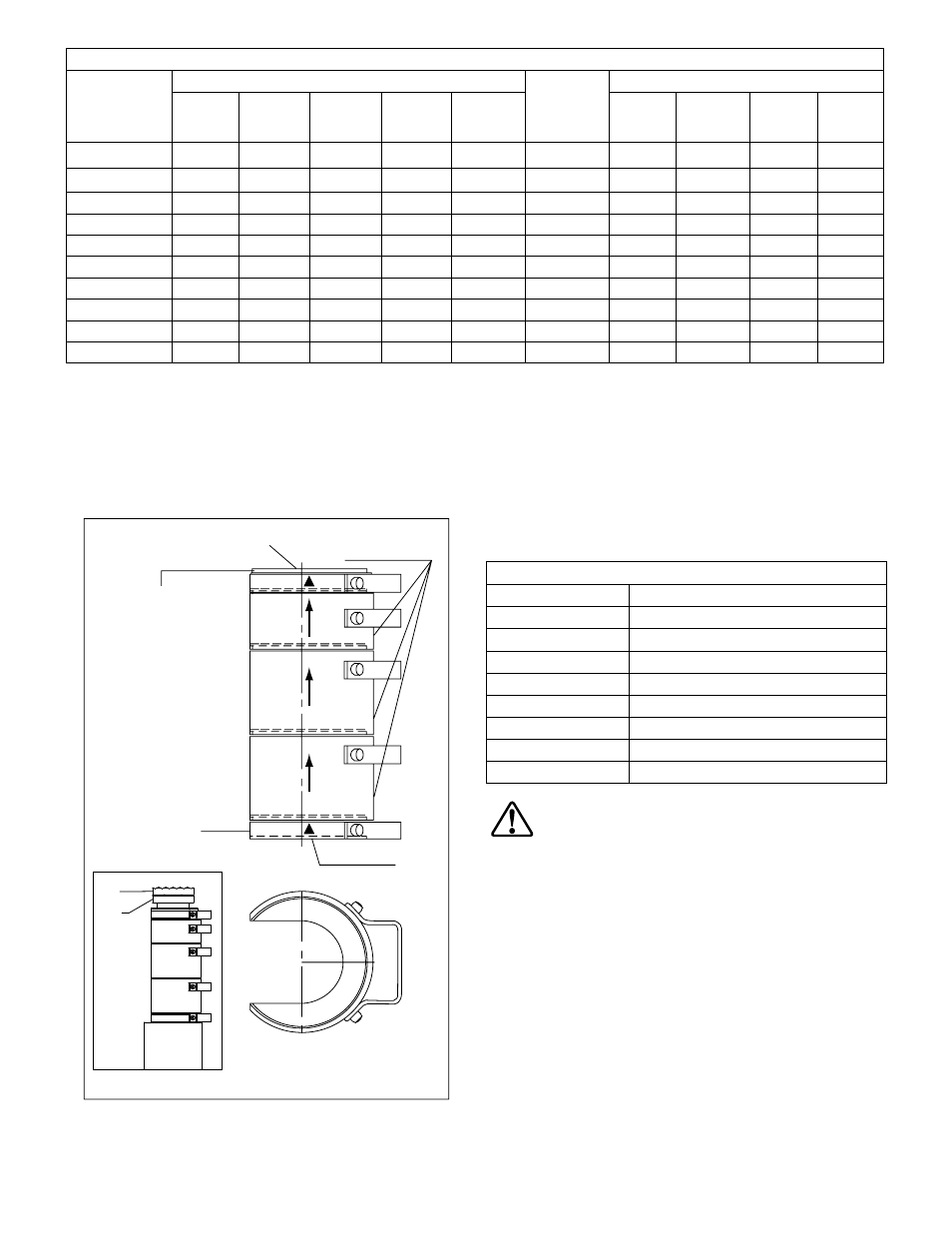

Assembled View

Load

Support

Ring

Load

Cap

Steel U-Ring

(top)

Recess of U-Ring

Steel U-Ring

(bottom)

Aluminum U-Rings

Locator (on each

U-Ring and at

top of cylinder

housing)

Figure 5, U-Ring Stacking Arrangement (typical)

6.0 MAINTENANCE

6.1 Maintain Oil Level in Hydraulic Reservoir

Check the hydraulic oil level every 30 days. Oil level should be

approximately 1 inch [25 mm] below top of reservoir, with cylinder

fully retracted and motor off .

If oil level is low, add Enerpac HF hydraulic oil as required. If

Enerpac HF is not available at the work site, use an equivalent

hydraulic oil that meets the specifi cations shown in Table 8.

Table 8 - Oil Specifi cations

ISO Grade

32

Viscosity Index

100 min

Viscosity at 210 °F

42-45 S.U.S.

Viscosity at 100 °F

150-165 S.U.S.

Viscosity at 0 °F

<12000 S.U.S.

API Gravity

31.0-33.0

Flash, C.O.C. °F

400

Pour Point, °F

-35

Paraffi

nic Base Color

Blue

CAUTION: Failure to use the proper oil may result in

damage to jack hydraulic components and will void the

product warranty. Use of Enerpac HF oil is strongly

recommended.

IMPORTANT: Be sure that the oil is clean. If the oil has a milky,

cloudy or dark appearance, it should be changed immediately as

described in Section 6.2.

6.2 Changing the Oil (See Figure 6)

Change the oil at least every 12 months.

Note: The following conditions will require more frequent oil

changes:

• Rigorous duty, where oil temperature may reach 150 °F

[60 °C].

• A high humidity environment and/or extreme changes in

temperature that can result in condensation inside the

reservoir.

• Dirty or dusty environments that may contaminate the oil.