Enerpac PR-Series Air User Manual

Page 6

WARNING: Failure to observe the following instructions

could allow load to shift or drop. Serious personal injury

and/or property damage may result.

When using PRE Series extensions and/or PRS Series spacers,

always obey the following rules:

• For loads up to 60 tons [54 metric tons]: Any two PRE Series

extensions may be included in the stacking arrangement,

provided that the maximum stack height (See Table 5) is not

exceeded and the following exceptions are observed:

1) Jack model

PRAMA06014L:

Only one PRE18 extension

can be included in the stacking arrangement.

2) All jack models ending in “16L”

:

Only one PRE11, PRE14

or PRE18 extension can be included in the stacking arrangement.

3) All jack models ending in “27L”

: Extensions PRE14 and

PRE18 cannot be included in the stacking arrangement.

These

extensions are designed for short stroke jacks only (models

ending in “14L” and “16L”).

•

For loads over 60 tons [54 metric tons], or strokes over

14 inches [356 mm]: Only one PRE Series extension and

one PRS Series spacer can be included in the stacking

arrangement.

• Never exceed 3 inches [76 mm] in total spacer height.

• Never exceed the maximum additional stack height for your

jack model. Refer to Table 5, dimension “X”.

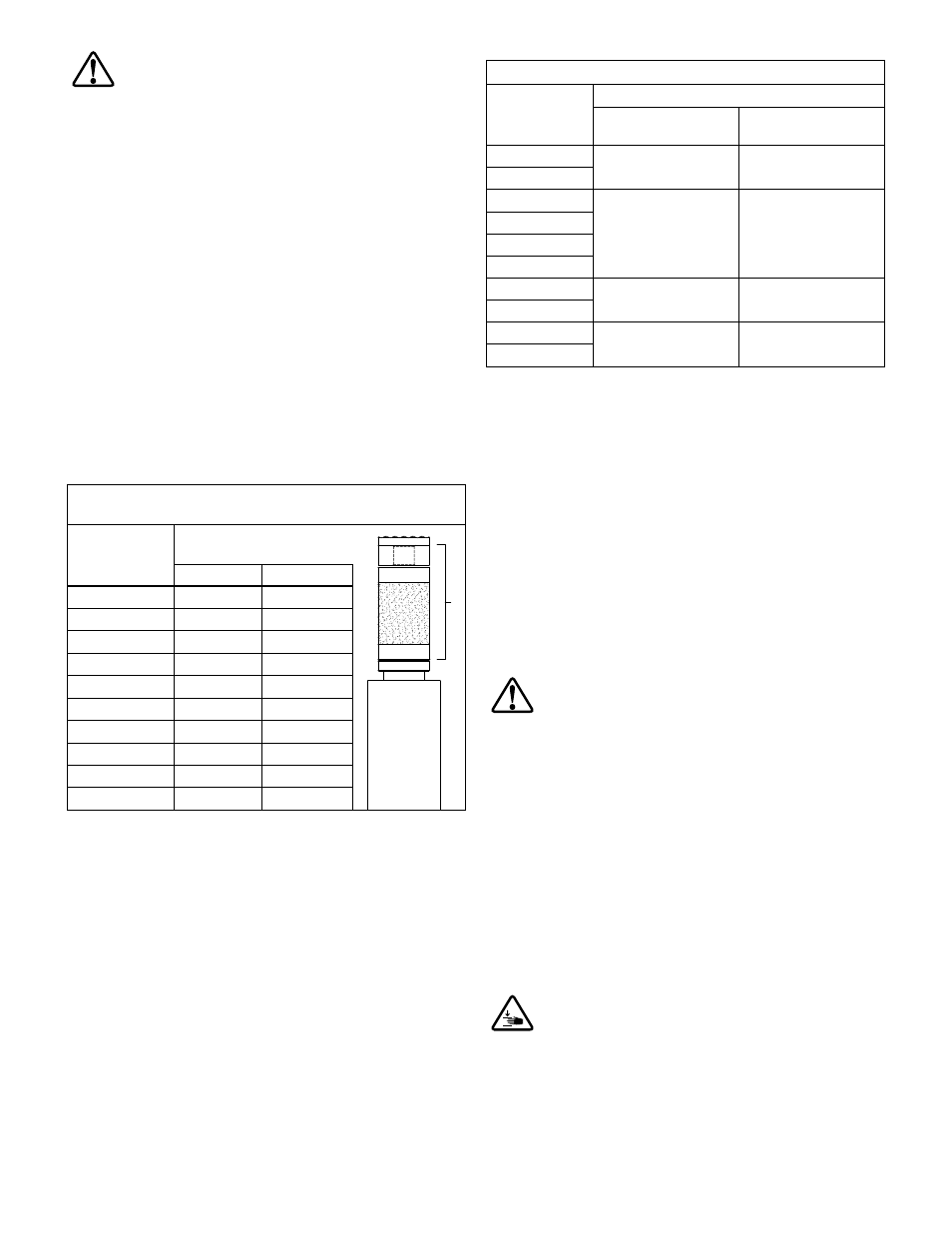

Table 5 - Maximum Additional Stack Height Using

Optional PRE Series Extensions and PRS Series Spacers

Jack Model

Maximum Additional Stack

Height (dimension “X”)

X

inches

mm

PRAMA06014L

32

813

PRAMA06027L

11

279

PRAMA10016L

21

533

PRAMA10027L

11

279

PRASA10016L

21

533

PRASA10027L

11

279

PRASA15016L

21

533

PRASA15027L

11

279

PRASA20016L

21

533

PRASA20027L

11

279

5.5 Load Caps

A non-swivel load cap is included with the jack as standard

equipment. A swivel load cap is available as an optional

accessory. Refer to Table 6 for a list of load cap model numbers.

IMPORTANT: Use a swivel load cap to properly engage angled

lifting points. A swivel load cap should always be used when the

amount of misalignment between the standard load cap and the

lifting point is too large to be compensated for by use of plywood

or other suitable compression material alone.

Table 6 - Load Caps

Jack Model

Load Cap Model Numbers

Non-Swivel

Load Cap (standard)

Swivel Load Cap

(optional accessory)

PRAMA06014L

42208E

PRTS60

PRAMA06027L

PRAMA10016L

42208E

PRTS60

PRAMA10027L

PRASA10016L

PRASA10027L

PRASA15016L

42208E

PRTS150

PRASA15027L

PRASA20016L

42208E

PRTS200

PRASA20027L

5.6 U-Ring Stacking Instructions

(See Figure 5)

Pow'r-Riser U-Rings (optional accessories) allow positive

mechanical load holding of a lifted load. The U-Rings are placed

on top of the cylinder housing and around the extended cylinder

rod. They are available in fi ve diff erent lengths for each Pow'r-

Riser model.

To help ensure proper alignment and installation, the top surface

of the cylinder housing and the top surface of each U-Ring

contains a raised locator. The bottom surface of each U-Ring

contains a mating recess.

The U-Rings are made of steel and aluminum. A steel U-Ring

must always be positioned at the top and bottom ends of the

U-Ring stack. The aluminum U-Rings must always be located

in the middle of the stack, between the two steel U-Rings. This

stacking arrangement helps prevent damage to the aluminum

U-Rings.

CAUTION: Never position an aluminum U-Ring at the

top or bottom end of the U-Ring stack.

Install U-Rings as described in the following steps:

1. Using the jack, raise the load to the desired lifting height.

Refer to the instructions in Section 5.3 of this manual.

2. Place one steel U-Ring on top of the cylinder housing,

around the extended cylinder rod.

3. As required, place one or more aluminum U-Rings on top

of the steel U-Ring, around the extended cylinder rod.

The quantity of aluminum U-Rings to be installed will vary,

depending on jack model, lifting height and the U-Ring set

being used. Refer to Table 7 for additional information.

4.

Place a second steel U-Ring at the top of the U-Ring stack.

IMPORTANT: Be sure the arrow on each U-Ring is pointing up.

Be sure all locators are fully engaged in the mating recesses of

the U-Rings.

CAUTION: Pinch point hazard: In the following step,

keep hands and fi ngers clear of area between load

support ring and top of U-Ring stack.

6