Mounting and wiring procedure – Det-Tronics X3300 Protect-IR Multispectrum IR Flame Detector User Manual

Page 7

Conduit raceways should be inclined so that water will

flow to low points for drainage and will not collect inside

enclosures or on conduit seals. If this is not possible,

install conduit drains above the seals to prevent the

collection of water or install a drain loop below the

detector with a conduit drain at the lowest point of the

loop.

The detector is factory sealed. Conduit seals are not

required for compliance with explosion-proof installation

requirements. Units with M25 thread must use an IP66

washer to prevent water ingress.

MOUNTING AND WIRING PROCEDURE

Refer to the procedure below and the listed table and

figures to mount and wire the X3300.

Table 4 –

X3300 Wiring Identification and Notes

Figure 1 – Detector Orientation Relative to Horizon

Figure 2 – Direct to Junction Box Mounting Option

Figure 3 – X3300 with Integral Swivel Mount

Figure 4 – X3300 with Q9001L Swivel Mount

Figure 5 – Front View of the X3300

Figure 6 – X3300 with Integral Swivel Mount Installation

Figure 7 – Typical System Wiring, Single Detector

Figure 8 – Typical System Wiring, Multiple Detector

Figure 9 – A Typical System, X3300 Detector with

Isolated 4 to 20 mA Output

Figure 10 – A Typical System, X3300 Detector with Non-

Isolated 4 to 20 mA Output

oi

PLATE ORIENTATION

Refer to Figure 5 and insure that the

oi plate will be

oriented as shown when the X3300 is mounted and

sighted. This will ensure proper operation of the

oi

system and will also minimize the accumulation of

moisture and contaminants between the

oi plate and

the viewing windows. The

oi plate includes an arrow,

which should be pointed in the up direction, indicating

that the

oi plate and detector are correctly oriented.

IMPORTANT

The

oi

plate must be securely tightened to ensure

proper operation of the

oi

system (40 oz./inches

recommended).

5

95-8480

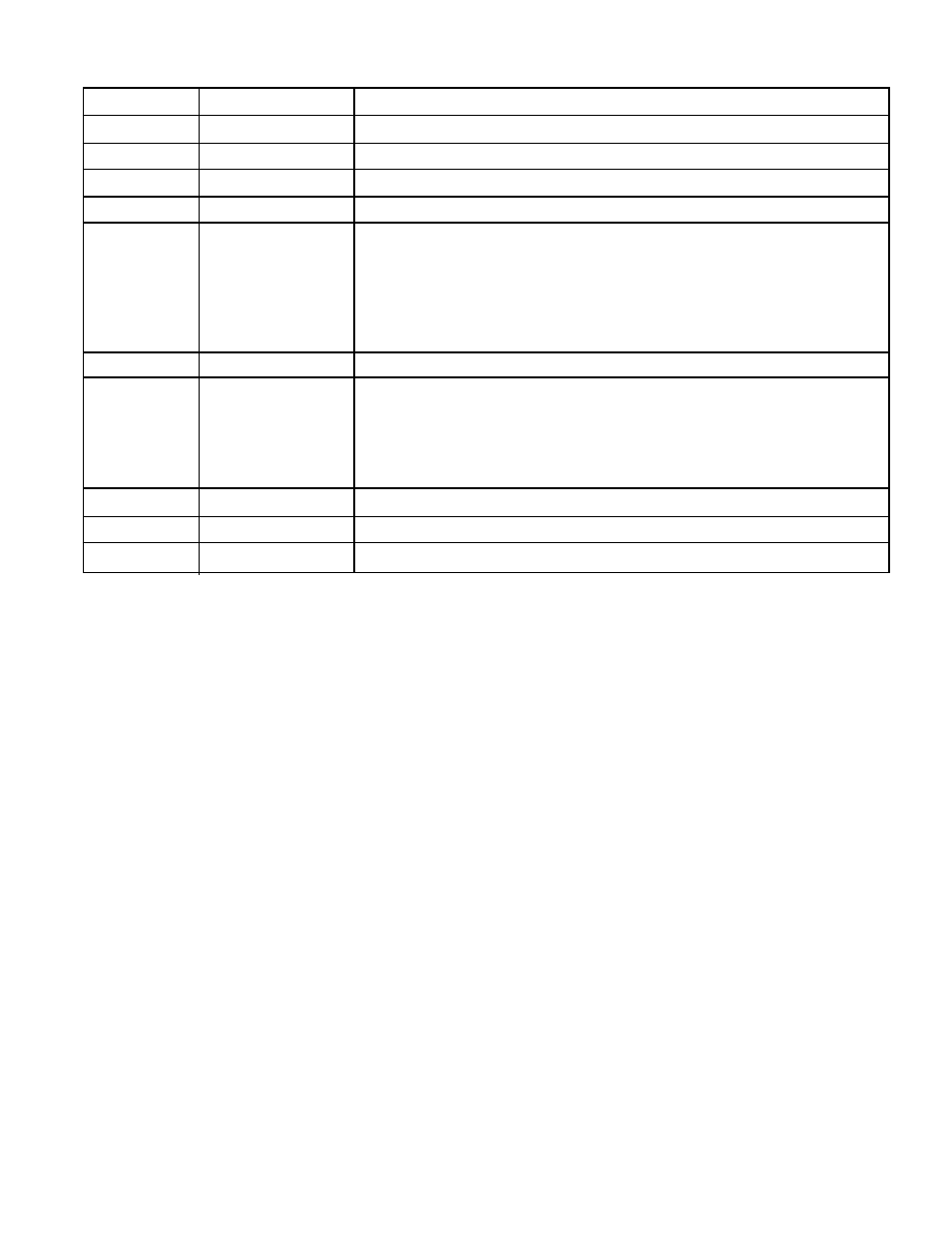

Wire Color

Function

Notes

Green

Chassis (Earth) Ground

Connect to junction box ground screw.

Black

(–) Negative

Connect to external 24 vdc power supply negative.

Red

(+) Positive

Connect to external 24 vdc power supply positive.

Blue and Pink**

Alarm Relay Common

• Two conductors provided for parallel wiring of alarm relay contacts.

Brown and Tan**

Alarm Relay

• Two conductors provided for parallel wiring of alarm relay contacts.

• Factory configured. Specify Normally Open or Normally Closed operation when

*

Normally Open (N.O.)

ordering.

OR

• Normally Open = Relay contacts are normally open (no fire) and close when a

Normally Closed (N.C.)

fire is detected.

• Normally Closed = Relay contacts are normally closed (no fire) and open when a fire

is detected.

Purple

Fault Relay Common

• Fault relay common wire.

Clear (gray)

Fault Relay

• Factory configured. Specify Normally Open or Normally Closed operation when

ordering.

*

Normally Open (N.O.) • Normally Open = Relay contacts are closed during normal operation and

OR

open when a fault is detected.

Normally Closed (N.C.)

• Normally Closed = Relay contacts are open during normal operation and

closed when a fault is detected.

White

Manual

oi Test

Connect to external switch to initiate Manual

oi Test.

Orange

Data –

Not in use. (Terminate or protect from connection)

Yellow

Data +

Not in use. (Terminate or protect from connection)

* Standard Configuration

** Red/White striped wire may be substituted for solid pink; Brown/White for solid tan.

Table 4—Wiring Identification and Notes