Replacement parts, Device repair and return, Ordering information – Det-Tronics X3300 Protect-IR Multispectrum IR Flame Detector User Manual

Page 21

19

95-8480

THREAD SIZE—

Conduit connection:

3/4 inch NPT or M25.

SHIPPING WEIGHT (Approximate)—

Aluminum:

2.4 pounds (1.1 kilograms).

Stainless Steel: 4.8 pounds (2.2 kilograms).

CERTIFICATION—

FMR:

Reference Appendix A.

CSA:

Class I, Div. 1, Groups B, C and D;

Class II, Div. 1, Groups E, F, and G;

Class III (T4A).

Class I, Div. 2, Groups A, B, C and D;

Class II, Div. 2, Groups F and G;

Class III (T3C).

Enclosure Type 4X.

Explosion-proof Ambient Temperature

Limits: –55°C to +125°C.

CENELEC:

Standard Temperature Model

EEx d IIC T6, EEx d e IIC T6

(T

amb

= –40°C to +60°C).

EEx d IIC T5, EEx d e IIC T5

(T

amb

= –40°C to +75°C).

IP66.

Extended Temperature Model

EEx d IIC T6, EEx d e IIC T6

(T

amb

= –55°C to +60°C).

EEx d IIC T5, EEx d e IIC T5

(T

amb

= –55°C to +75°C).

EEx d IIC T4, EEx d e IIC T4

(T

amb

= –55°C to +100°C).

IP66.

Special Conditions for Safe Use (“X”):

The extended temperature model can withstand

repeated exposures to +125°C for periods of up to 12

hours while maintaining its explosion-proof rating. It is

recommended that the unit housing be replaced after

500 hours of exposure to the +125°C temperature

condition to maintain flame-proof ratings.

CE:

Conforms to all relevant European

norms.

NOTE

Operational performance verified from -40°C to

+75°C.

WARRANTY PERIOD—

5 years, sensor and electronics.

REPLACEMENT PARTS

The detector is not designed to be repaired in the field.

If a problem should develop, refer to the

Troubleshooting section. If it is determined that the

problem is caused by an electronic defect, the device

must be returned to the factory for repair.

DEVICE REPAIR AND RETURN

Prior to returning devices, contact the nearest local

Detector Electronics office so that a Service Order

number can be assigned. A written statement

describing the malfunction must accompany the

returned device or component to expedite finding the

cause of the failure.

Pack the unit properly. Use sufficient packing material

in addition to an antistatic bag or aluminum-backed

cardboard as protection from electrostatic discharge.

Return all equipment transportation prepaid to the

factory in Minneapolis.

NOTE

Since the entire unit must be returned to the

factory for repair, it is highly recommended that a

complete spare be kept on hand for field

replacement to ensure continuous protection.

ORDERING INFORMATION

When ordering, refer to Table 6, Ordering Factory

Configuration. For further information on the function of

each configuration option, refer to Table 2.

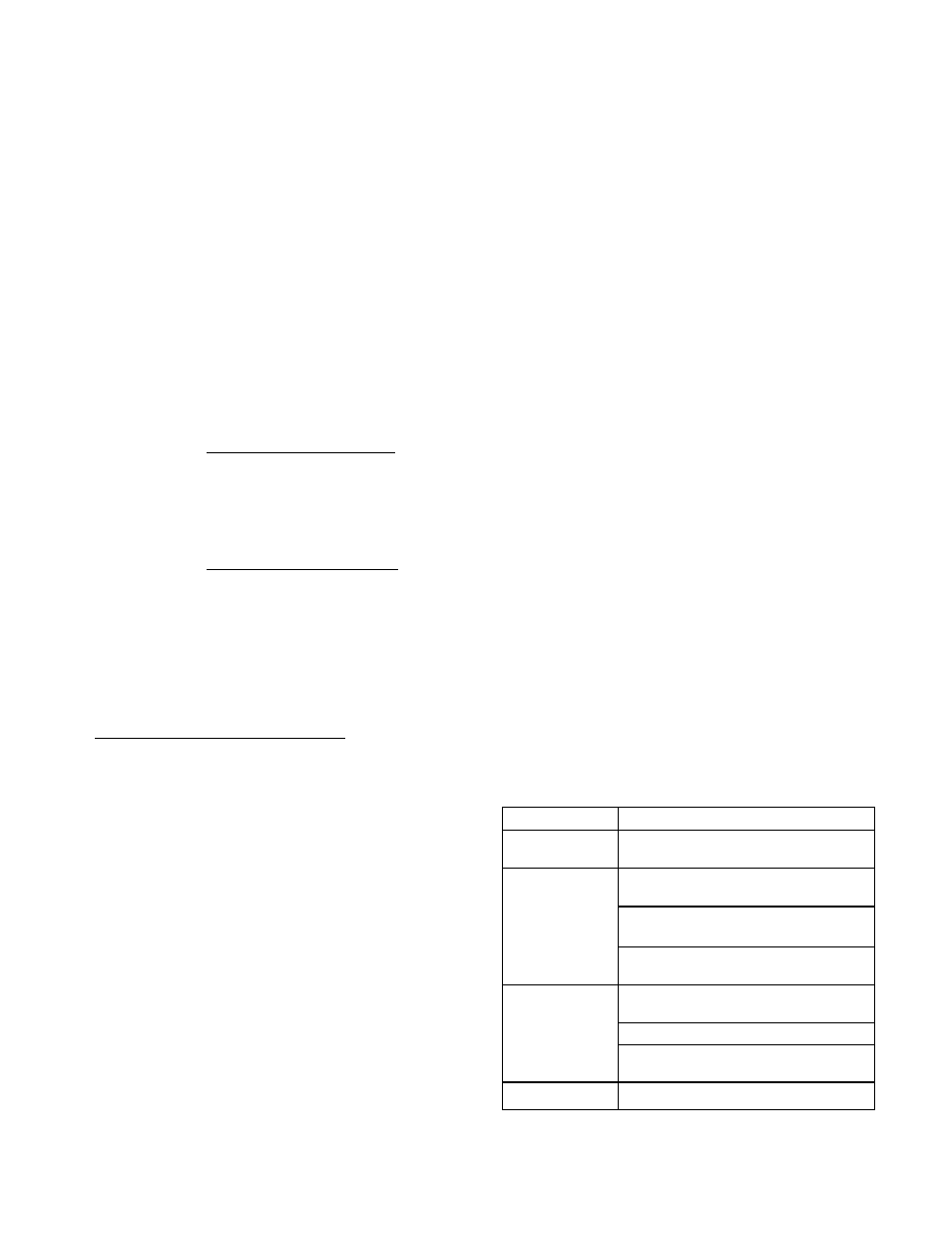

Table 6—Ordering Factory Configuration Options

Option

Available Configurations

Optical Integrity (

oi)

* Automatic

oi/manual oi

• Manual

oi (only)

Fire Relay

• Latching

* Non-latching

• Normally Energized

* Normally De-Energized

* Normally Open

• Normally Closed

Fault Relay

• Latching

* Non-latching

* Normally Energized

* Normally Open

• Normally Closed

4 to 20 mA Output

• With Fire and Fault Relay

* Standard Configuration