Installation, Wiring requirements – Det-Tronics X3300 Protect-IR Multispectrum IR Flame Detector User Manual

Page 6

INSTALLATION

DETECTOR POSITIONING

Detectors should be positioned to provide the best

unobstructed view of the area to be protected. The

following factors should also be taken into consideration:

• Identify all high risk fire ignition sources.

• Be sure that enough detectors are used to adequately

cover the hazardous area.

• Locate and position the detector so that the fire

hazard(s) are within both the field of view and

detection range of the device. Refer to Appendix A

for specific information.

• Be sure that the unit is easily accessible for cleaning

and other periodic servicing.

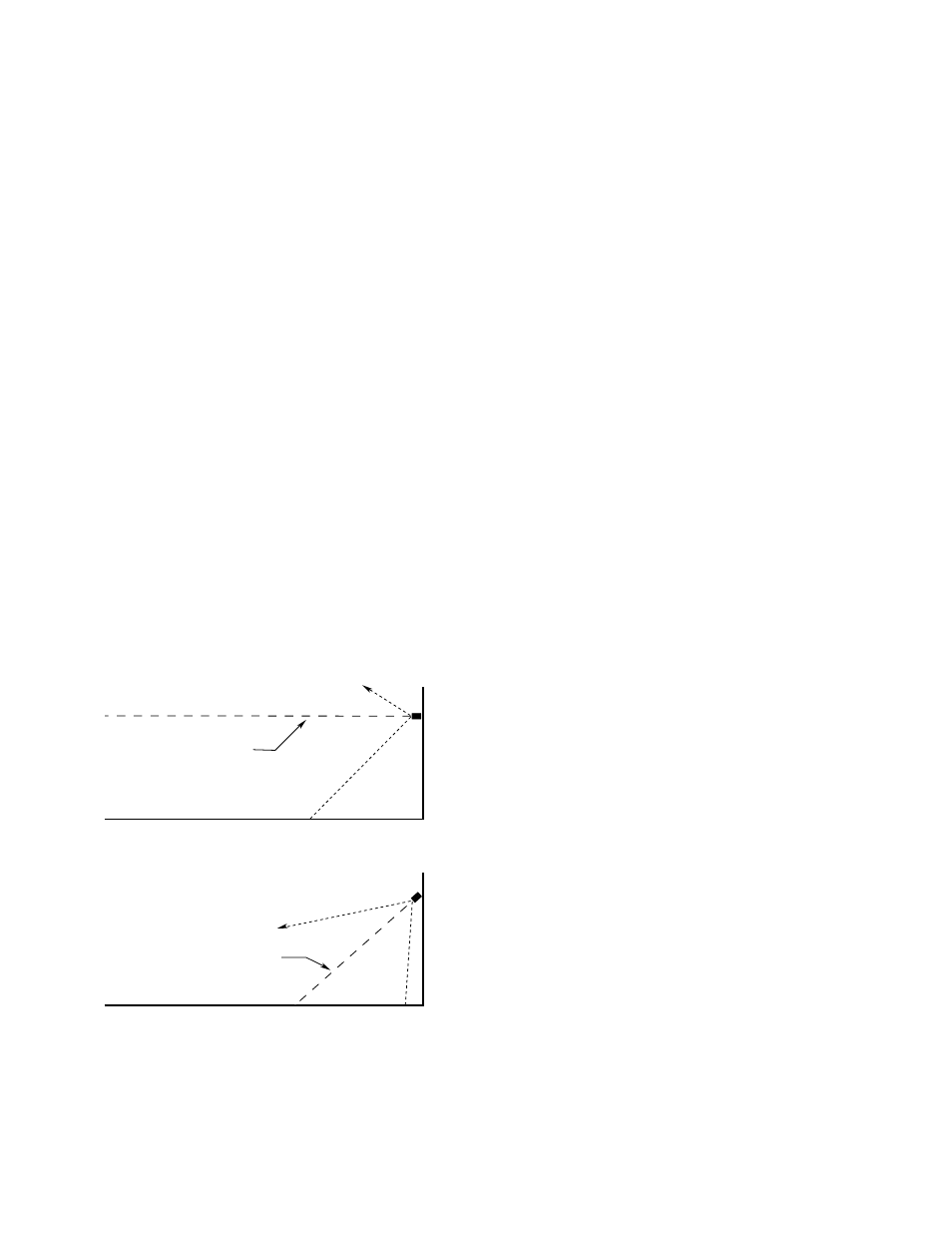

• For outdoor applications, the detector should be

aimed downward at least 10 to 20 degrees to allow

lens openings to drain. See Figure 1. The detector

should be positioned so that its field of view does not

cover areas outside the hazardous area. This will

minimize the possibility of false alarms caused by

activities outside the area requiring protection.

• For best performance, the detector should be

mounted on a rigid surface in a low vibration area.

• Dense fog, rain or ice can absorb IR radiation and

reduce the sensitivity of the detector.

• Although IR detectors are less affected by smoke than

other detectors, the X3300 should not be placed

where rising combustion products can obscure its

vision. If smoke is expected before fire, smoke or

other alternative detectors should be used in

conjunction with the X3300. For indoor applications, if

dense smoke is expected to accumulate at the onset

of a fire, mount the detector on a side wall at least a

few feet (approximately 1 meter) down from the

ceiling.

• If possible, fire tests should be conducted to verify

correct detector positioning and coverage.

WIRING REQUIREMENTS

WIRE SIZE AND TYPE

The system should be wired using a 14 to 22 gauge (1.3

to 0.5 mm2) cable. The wire size selected should be

based on the number of detectors connected, the

supply voltage and the cable length. A minimum input

voltage of 18 vdc must be present at the X3300.

The use of shielded cable is recommended to protect

against interference caused by EMI and RFI. When

using cables with shields, terminate the shields as

shown in Figures 7 through 10. Consult the factory if not

using shielded cable.

In applications where the wiring cable is installed in

conduit, the conduit should not be used for wiring to

other electrical equipment.

CAUTION

Installation of the detector and wiring should be

performed only by qualified personnel.

PROTECTION AGAINST MOISTURE DAMAGE

It is important to take proper precautions during

installation to ensure that moisture will not come in

contact with the electrical connections or components

of the system. The wiring pigtail for the X3300 is factory

sealed for easy installation onto a junction box where

electrical connections are made. The integrity of the

system regarding moisture protection must be

maintained for proper operation and is the responsibility

of the installer.

If conduit is used, drains must be installed at water

collection points to automatically drain accumulated

moisture. Conduit breathers should be installed at

upper locations to provide ventilation and allow water

vapor to escape. At least one breather should be used

with each drain.

4

Figure 1—Detector Orientation Relative to Horizon

CENTER AXIS

OF DETECTOR

FIELD OF VIEW

CENTER AXIS

OF DETECTOR

FIELD OF VIEW

INCORRECT

CORRECT

NOTE: DETECTOR MUST ALWAYS BE AIMED

DOWNWARD AT LEAST 10 TO 20 DEGREES.

B1974