Sensor response, Factors affecting sensor sensitivity – Det-Tronics 505 Combustible Gas Detector Transmitter with Combustible Gas Sensor CGS User Manual

Page 5

2

95-8472

3.1

SENSOR RESPONSE

Figure 2 shows the typical response of a catalytic gas

sensor to various levels of methane. Note that a reading

of 40% LFL will be given at 2.0% by volume methane and

also at 80.0% by volume methane, which is well above

the upper flammable limit. Although gas concentrations

above the upper flammable limit will not propagate a

flame, it is likely that somewhere in the protected area

there may be a flammable concentration.

All catalytic sensors require oxygen to accurately measure

combustible gas concentrations. Sensor response and

accuracy will decrease when the oxygen level is less

than 10%. Figure 3 shows the effect of oxygen enriched

and oxygen deficient atmospheres on the response of

a typical catalytic gas sensor. Do not use catalytic gas

sensors in areas where the oxygen level is less than 10%

by volume.

FACTORS AFFECTING SENSOR

SENSITIVITY

There are a variety of factors that can cause a decrease in

the sensitivity of catalytic type combustible gas sensors.

The following information identifies the most common

substances that can have a detrimental effect on the

catalytic gas sensor. Under no circumstances should

these lists be considered as all inclusive.

Interfering or contaminating substances include

materials that can clog the pores of the sintered steel

flame arrestor and reduce the gas diffusion rate to the

sensor. Examples include:

1. Dirt or oil.

A dust cover or splash guard should be installed to

protect the flame arrestor. The dust cover may be

cleaned using an organic solvent and an ultrasonic

bath unless the contaminant is insoluble. Replace

dust cover if there is any doubt.

2. Corrosive liquids and vapors.

This can occur when substances such as H2S,

(hydrogen sulfide), Cl2 (chlorine) or HCl (hydrochloric

acid) are present. A dust cover may provide some

limited protection. Routine calibration frequency

should be increased in applications where corrosive

materials are present.

3. Flame arrestor clogged as a result of painting or

cleaning.

The routine maintenance procedure should include

first powering down the system, then covering the

sensor with a plastic bag when painting or cleaning.

The bag should be removed as soon as possible

when the procedure is complete. Recalibrate the

sensors after re-powering and stabilization.

4. Polymer formation in the flame arrestor.

This can occur where monomeric vapors such as

1-3 butadiene, styrene, isoprene, etc. are present.

This may render the sensor dead.

Some substances can cover or tie up the active sites on

the catalytic surface of the active sensing element. This

occurs in the presence of volatile metal organics, gases,

hydride vapors, and volatile compounds containing

phosphorous, boron, silicon, etc.

Examples:

Tetraethyl lead

Phosphine

Diborane

Silane

Trimethyl

chlorsilane

Hydrogen

fluoride

Boron trifluoride

Phosphate

esters

Silicone oils and greases

RTV silicone sealants

Some substances react with the catalytic element metal,

forming a volatile compound. This erodes the metal from

the surface. With sufficient exposure, most or all of the

metal catalyst can be removed from the surface of the

active element of the sensor. Halogens and compounds

that contain halogens are materials of this nature.

Examples: Chlorine

Bromine

Iodine

Hydrogen Chloride, Bromide or Iodide

Organic

halides

Trichloroethylene

Dichlorobenzene

Vinyl chloride

Freons

Halon 1301

(Bromotrifluoromethane)

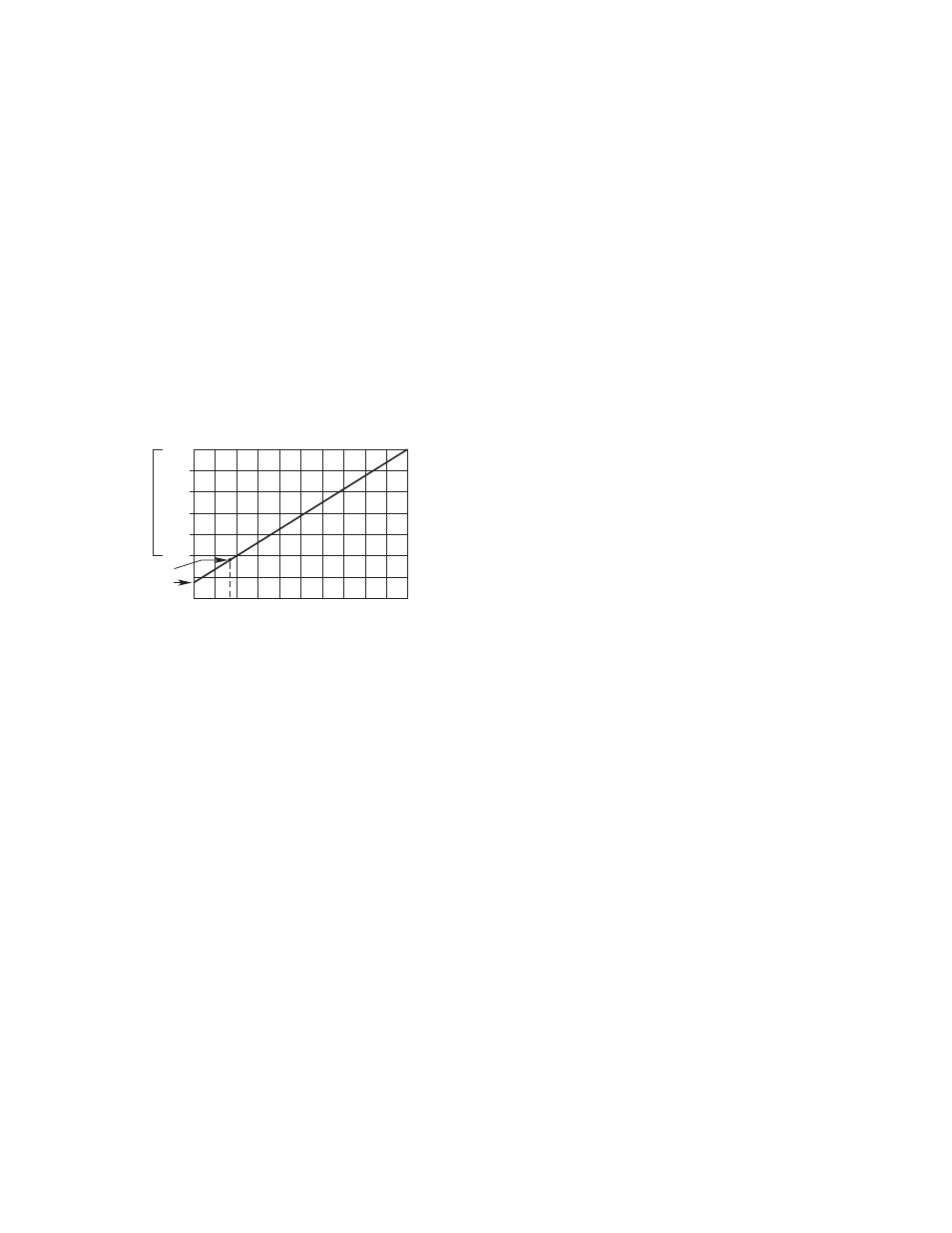

0 2 4 6 8 10 12 14 16 18 20

100%

80%

60%

40%

20%

0%

MILLIAMPERES DC

A1945

CALIBRATE MODE

LFL

PERCENTAGE

3.4

FAULT

Figure 1—Transmitter DC Current Output