Det-Tronics 505 Combustible Gas Detector Transmitter with Combustible Gas Sensor CGS User Manual

Page 10

7

95-8472

3.1

Conduit Seals, Drains, and Breathers

The Model 505 Transmitter is designed and approved for

use in hazardous areas where explosion-proof equipment

certification is required. When installing the Model 505

in such areas, explosion-proof conduit seals should

be installed within 18 inches (46 cm) of the transmitter

housing. Conduit seals prevent the passage of vapors

or flames through the conduit. Seals are recommended

even if they are not required by local wiring codes.

Conduit systems are never completely air-tight. As a

result, significant amounts of condensation can form

within the conduit system. Therefore, it is important to

take proper precautions during installation to ensure that

moisture will not cause damage to the transmitter or other

components of the system.

Conduit raceways should be inclined so that water will flow

to low points for drainage and will not collect on conduit

seals or inside enclosures. If this is not possible, install

conduit drains above the seals to prevent the collection

of water, or install a drain loop below the detector with a

conduit drain at the lowest point of the loop.

Conduit drains should be installed at water collection

points to automatically drain accumulated moisture.

Conduit breathers should be installed at upper locations

to provide ventilation and allow water vapor to escape.

At least one breather should be used with each drain.

When using steel wire armored or mineral-insulated

copper-sheathed cable, select an approved gland with

a watertight compression stage and an overall gland

shroud for outdoor applications. A sealing washer must

be fitted between the gland and the conduit/cable entry

to ensure IP66 rating.

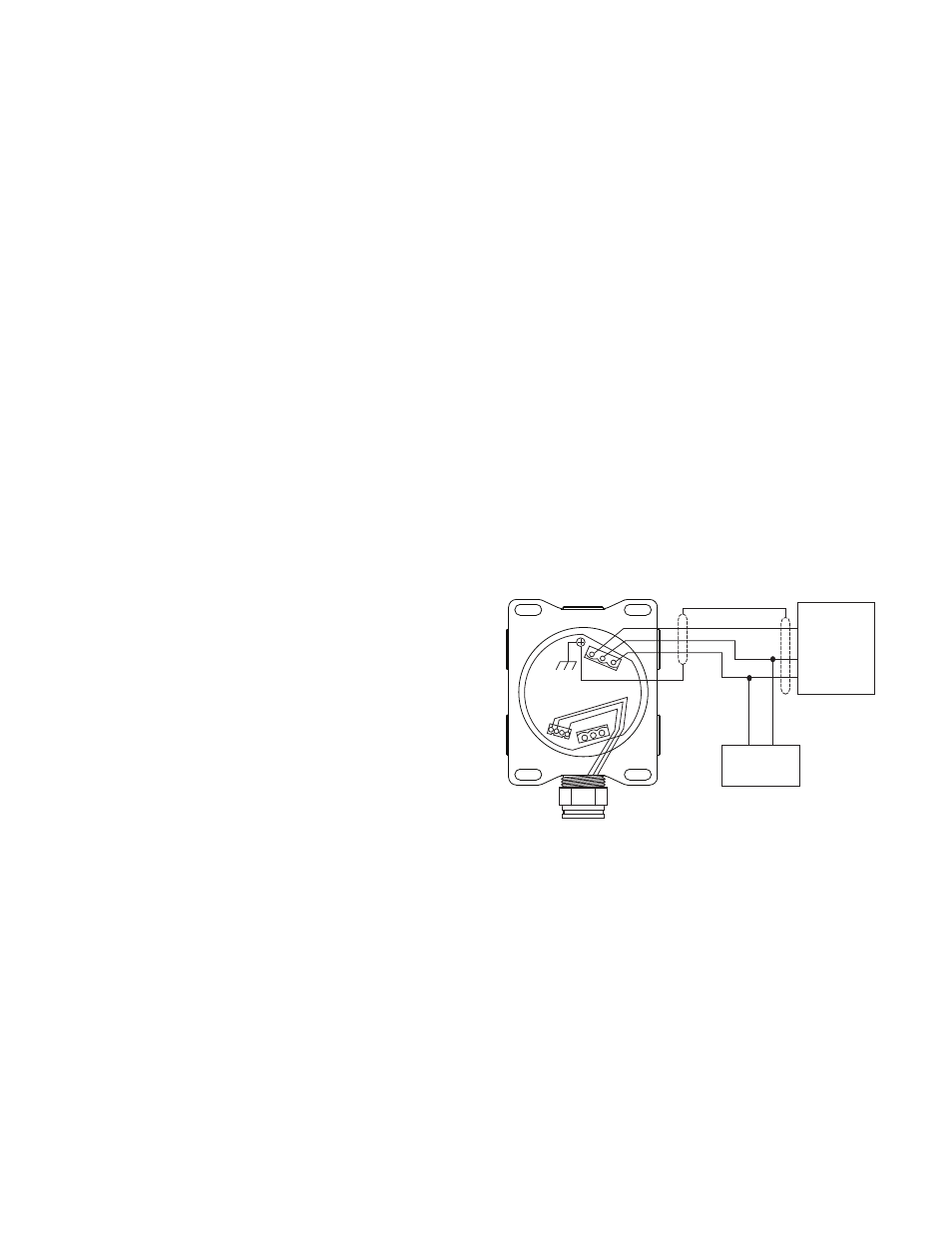

MODEL 505 WIRING

Wire the Model 505 as shown in Figure 6.

SENSOR SEPARATION

For maximum EMI/RFI protection, it is preferable to

mount the sensor directly to the Model 505 junction

box. However, in many cases it is desirable to locate

the sensor in a remote location where early gas detection

is most probable, and install the transmitter in an easy-

access location. In this case, a Sensor Termination Box

(available from Detector Electronics) should be used to

install the sensor separately from the transmitter. See

Figure 7.

A continuous, three conductor cable with an overall foil

shield must be used with the sensor separation kit. The

cable shield drain wire should be cut back and insulated

within the sensor junction box and connected to earth

ground at the transmitter junction box. Failure to use a

shielded cable or properly ground the shield is likely to

result in nuisance alarms caused by EMI/RFI problems.

The maximum separation distance between the sensor

and transmitter is limited by the electrical resistance of

the connecting wiring, which is a function of the gauge

of the wire being used. Table 1 gives the recommended

and absolute maximum sensor separation distances. If

the distance is less than the recommended maximum,

no adjustment to sensor voltage is required, although

measurement of the sensor voltage is recommended to

verify proper sensitivity. If the distance is greater than

the recommended maximum, refer to the “Sensor Voltage

Adjustment” section.

Sensor separation installations with the Model 505 require

a special terminal plug for connecting the sensor wiring

to the transmitter. This connector (P/N 102883-001) is

included with the Sensor Termination Box, and is also

available separately for existing installations.

NOTES:

1. DO NOT APPLY POWER TO THE TRANSMITTER WITH THE JUNCTION BOX COVER

REMOVED UNLESS THE AREA HAS BEEN DE-CLASSIFIED.

2. POSITION THE TRANSMITTER WITH THE SENSOR POINTING DOWN.

3. THE TRANSMITTER JUNCTION BOX SHOULD BE ELECTRICALLY CONNECTED TO

EARTH GROUND.

4. ATTACH THE SENSOR TO THE JUNCTION BOX TIGHTLY ENOUGH TO ENSURE AN

EXPLOSION-PROOF INSTALLATION, HOWEVER, DO

NOT OVERTIGHTEN. LUBRICATE

THE THREADS WITH THE CORRECT LUBRICANT TO EASE INSTALLATION AND

FUTURE REPLACEMENT.

SILICONE BASED LUBRICANTS MUST NEVER BE USED.

5. CABLE SHIELDS SHOULD BE CONNECTED TO EARTH GROUND AT ONE END ONLY.

6. SHIELDS SHOULD BE STRIPPED BACK FROM CONDUCTORS ONLY WITHIN THE

JUNCTION BOX ENCLOSURE.

–

SIG

RED

SENSOR

WHT

BLK

+

CONTROLLER

4 TO 20 MA

24 VDC

–

–

+

+

C1938

Figure 6—Model 505 Transmitter Wiring Without Sensor Separation