Det-Tronics 505 Combustible Gas Detector Transmitter with Combustible Gas Sensor CGS User Manual

Page 14

11

95-8472

3.1

1. Use formula: C x K = S

C = Concentration of calibration gas in % LFL = 50

K = K-factor from Table 1 in 76-1017 = 1.44

50 x 1.44 = 72

S = 72

2. Use formula: (S x 0.0067) + 0.17 = S1

S = span output level (determined in step 1) = 72

(72 x 0.0067) + 0.17 = S1

(72 x 0.0067) = 0.48

0.48 + 0.17 = 0.65

S1 = 0.65

3. Calibrate the Model 505 for a reading of 0.65 Vdc on

the voltmeter with a calibration mixture of 50% LFL

methane applied to the sensor.

NOTE

This procedure applies only to the Model 505

Transmitter. Other Det-Tronics transmitters use the

standard K-factor formula.

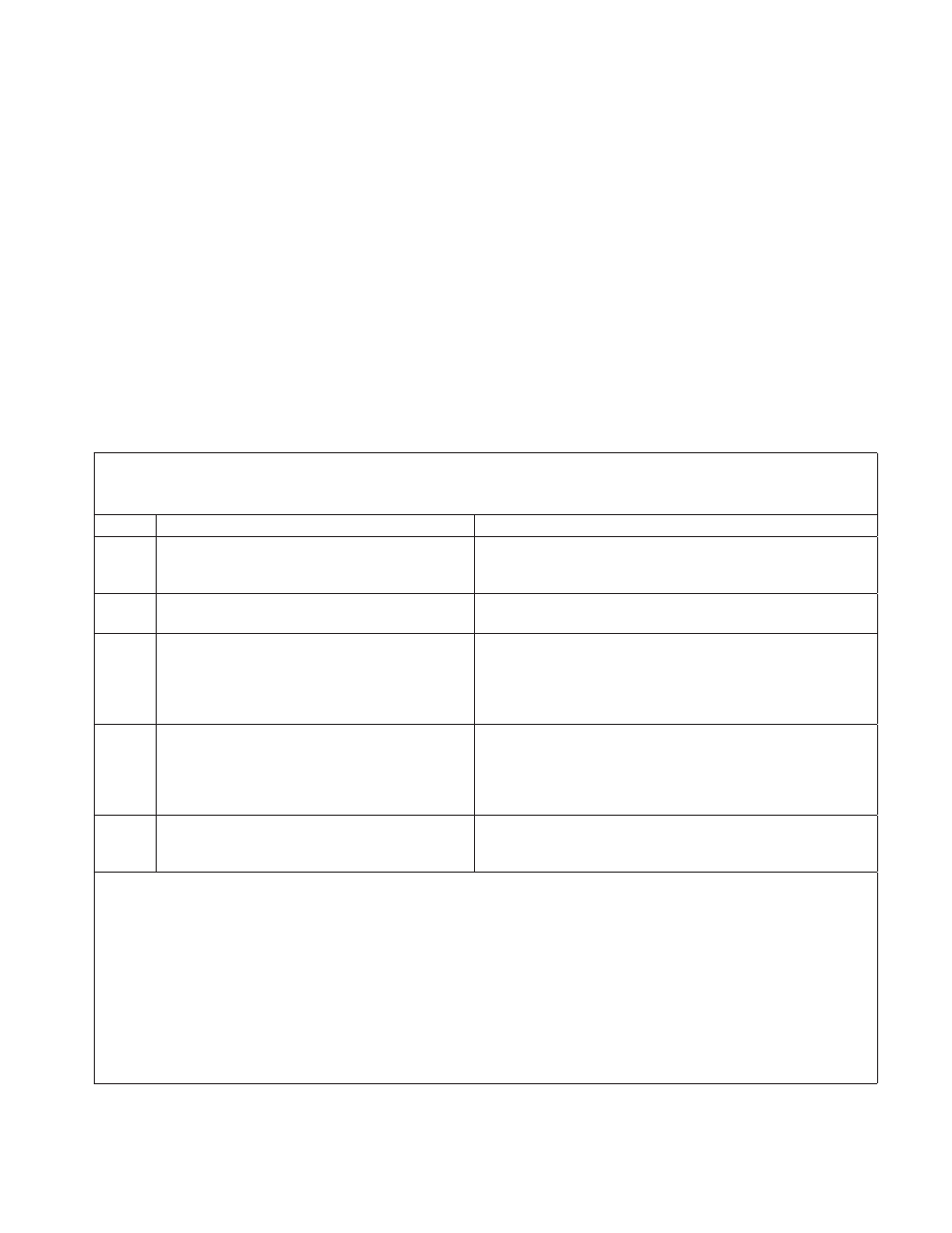

Table 2—Calibration Procedure

WARNING

Before removing the junction box cover, verify that no dangerous levels of gas are present.

Step

Switch Position

Operator Action

1

CAL/NORM switch in the CAL position.

1. LED turns on.

2. Connect a digital voltmeter to the transmitter test jacks.

3. Set the meter range to 2 Vdc.

2

ZERO/SPAN switch in the ZERO position.

1. Adjust the ZERO potentiometer to read 0.000 Vdc on the

voltmeter. See Note 3 below.

3

ZERO/SPAN switch in the SPAN position.

1. Adjust the 4 mA potentiometer to read 0.167 Vdc on the

voltmeter.

2. Apply the 50% LFL calibration gas to the sensor. When the

output has stabilized, adjust the SPAN potentiometer for a

reading of 0.500 on the voltmeter.

4

ZERO/SPAN switch in the ZERO position.

1. Sensitivity test. The meter must read greater than 0.015 Vdc.

See Note 4 below.

2. Remove the calibration gas.

3. When the meter reads 0.002 Vdc or less, remove the test

probes.

5

CAL/NORM switch in NORM position.

1. The LED turns off.

2. The calibration is complete.

3. Replace the junction box cover.

NOTES:

1. When the CAL/NORM switch is in the CAL position, the yellow LED turns on and the 4 to 20 mA output signal goes to 3.4 mA.

2. The voltmeter must be suitable for use in a hazardous location.

3. If the possibility of background gases exists, purge the sensor with clean air prior to the zero adjustment to assure accurate

calibration.

4. A typical sensitivity reading with 50% LFL gas applied to the sensor is 35 to 50 millivolts for a new sensor. Sensor replacement

is recommended when the sensitivity reading is less than 15 millivolts.

5. If a dust cover or splash shield is used, inspect it to be sure that it is not dirty or plugged. A plugged dust cover can restrict

the flow of gas to the sensing element, seriously reducing its effectiveness. For optimum performance, sensor covers/filters

should be replaced frequently to ensure that they are not degraded or plugged.