General information – Condux Winch Line Blower System User Manual

Page 4

CONDUX WINCH LINE BLOWER

2

1. General Information

Purpose of the Winch Line Blower

The Condux Winch Line Blower is a unique device for inserting winch lines directly into

underground conduit before cable pulling or conduit proving operations. The winch line blower is

comprised of three main parts that, when used in conjunction with an air compressor and a cable

pulling winch mechanism (truck, trailer, or portable), will propel a standard steel winch cable into

an unobstructed, unoccupied, airtight, plastic conduit run at an average speed of 100 feet per

minute.

The Condux winch line blower will work with nearly all type of existing steel cable winches that

are currently being used for the installation of underground

utility cables.

Because of the unique design of the winch line blower, it will

operate in a wide range of conduit sizes, from 2to 6 inch duct,

and with various diameter winch lines up 7/8” (14mm)

without compromising efficiency.

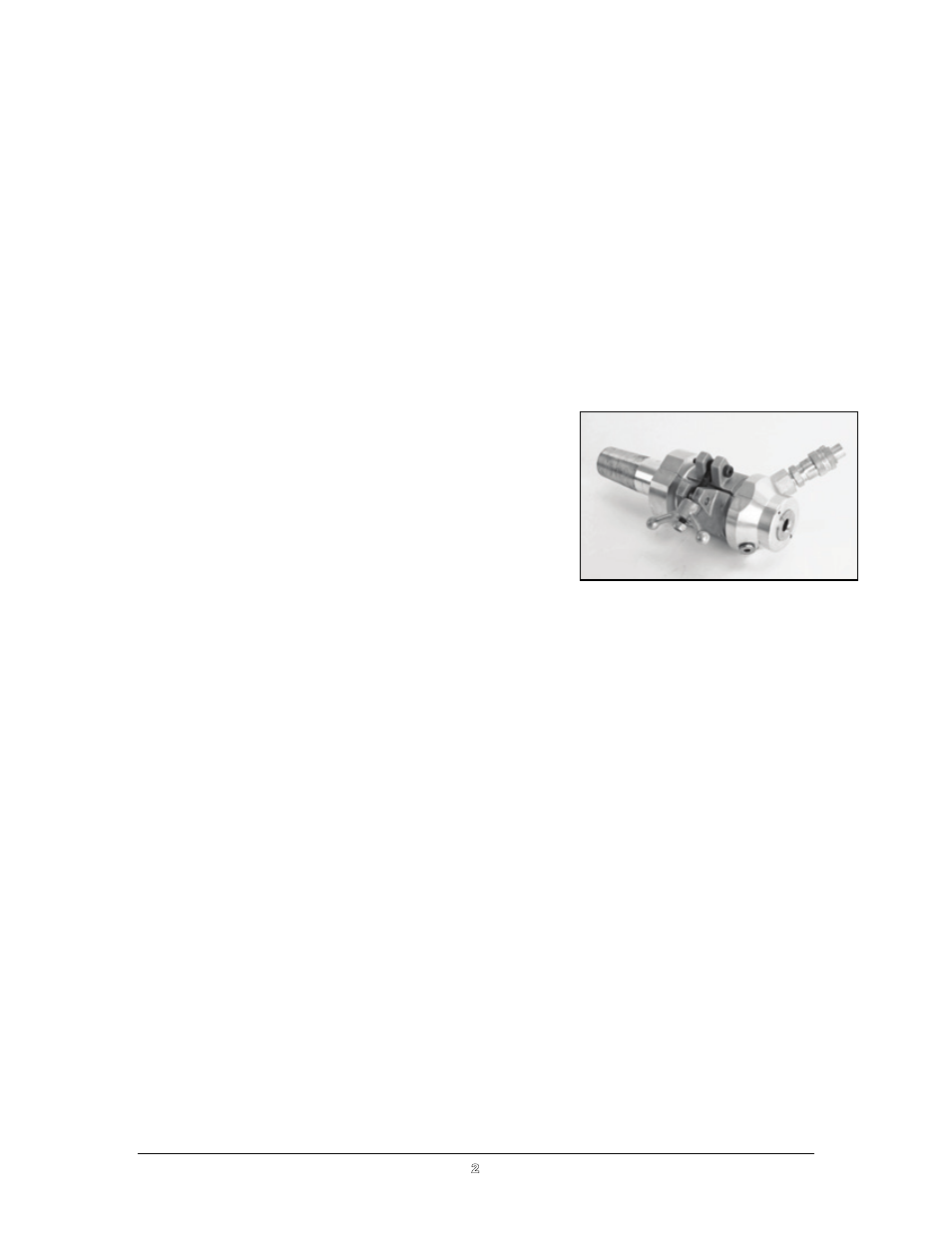

The three main parts of the winch line blower are the

winchline blower body assembly, the missile and the control valve assembly. When each part of

the system is properly installed and maintained, this provides a means of using existing winch line

equipment to speed up cable installation procedures by as much as 1000 percent.

Technical Information

1.

CONDITION OF USE

Temperature from 21° F (-6 C) to 110 F (+43 C)

Humidity from 30% to 90% +/- 5%

Weather conditions relevant to working conditions

Natural and/or artificial lighting of the worksite, minimum 200 lux

2.

AIR COMPRESSOR REQUIREMENTS

Pneumatic Pressure: 175 psi (12 bar) Maximum

Required Flow Capacity: 375 SCFM (11 m

3

/min) Maximum

Control valve air hose fittings need to be compatible with Dixon “Air King”

universal couplings.

Safety Pop-off Valve on Control Assembly set for 90 psi.