Step 1 splitter system outlets, Step 3 installation of assembled basin – Clarus Environmental Tru-Flow Splitter System User Manual

Page 2

2

© Copyright 2011. All rights reserved.

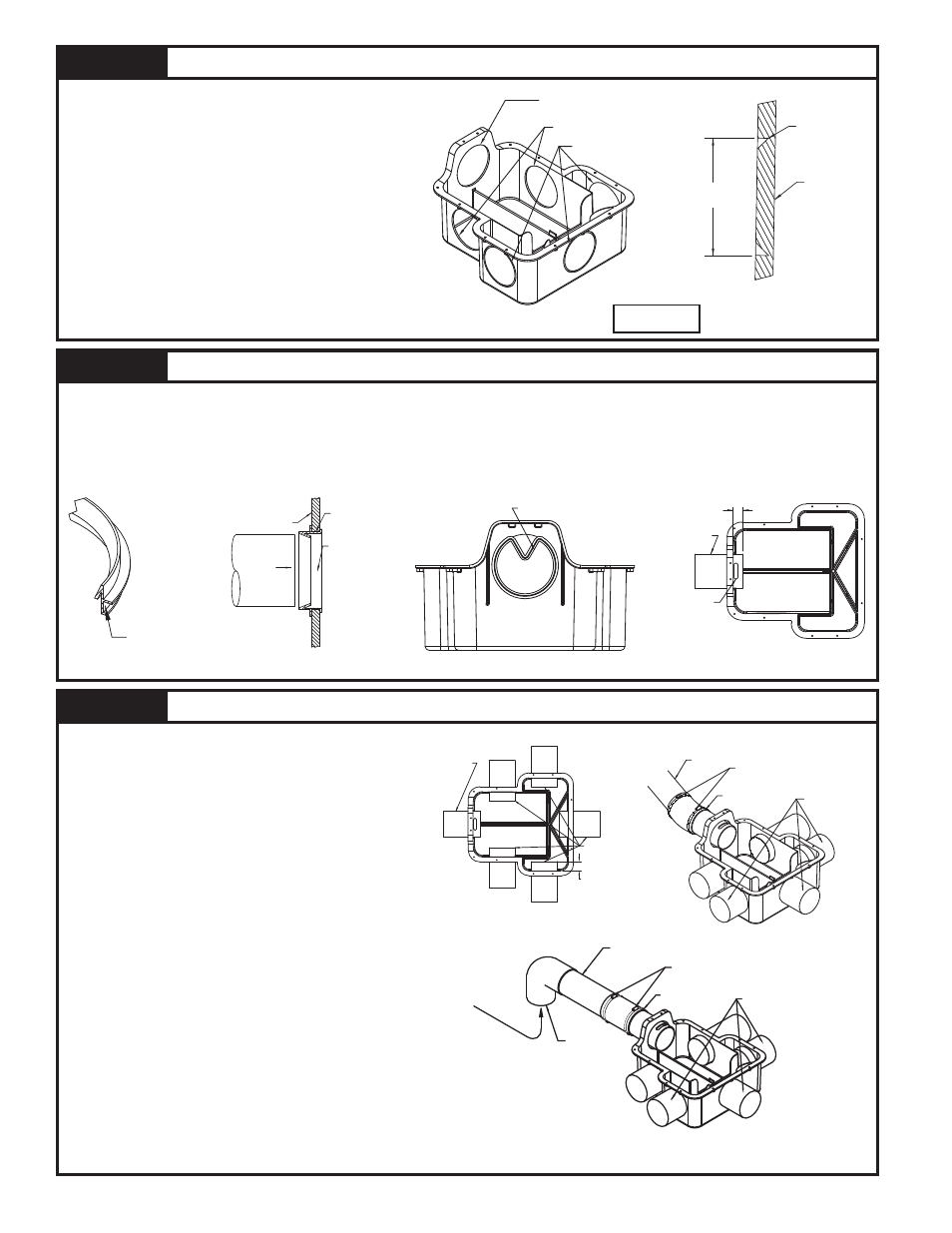

STEP 1

Splitter System Outlets

1.1) Determine the number of outlets to be used on

the splitter system based on the layout of the

trench field. When pumping to the splitter system,

optimum results are obtained if:

a.) Installations requiring 4 slot openings/trench

lines utilize slot openings 1,2,4, & 5.

b.) Installations requiring 3 slot openings/trench

lines utilize slot openings 1,3, & 5.

1.2) Score and cut through with a knife at the bottom of

v-groove. If required score several times around and

cut through.

DO NOT HIT WITH A HAMMER.

1.3) Trim and clean the diameter of the hole, leaving it

the same as the molded diameter.

DO NOT OVER

TRIM DIAMETER. Refer to Figure 2.2

STEP 2

Installation of Pipe Seals and Slotted Pipe Nipple

Splitter system is supplied with pipe seals for 4" SDR35 pipe. If using 4" SCH40 pipe, order P/N 173-0006.

2.1) Apply sealant around mating surface of pipe seal as shown in Figure 2.1. Repeat for each required pipe seal.

2.2) Place pipe seals in necessary holes as shown in Figure 2.2 & Figure 2.3.

2.3) Insert slotted pipe nipple through the inlet hole and pipe seal, pushing through about ¾". See Figure 2.4.

Note: Assure the slot end of the pipe nipple is inside the basin and the slot is facing upward and centered.

Figure 2.1

Figure 2.3

STEP 3

Installation of Assembled Basin

3.1) Set basin into place.

3.2) Insert necessary trench pipes into basin, pushing

through approximately 1½". See Figure 3.1. The

number of pipes varies for each installation.

3.3) Connect the inlet pipe to slotted pipe nipple with a

coupling (flexible rubbers shown). Do not tighten

coupling at this time. If used see Figure 3.2.

3.4) Installations in which the splitter system will be pumped

to are required to have at least a 3' length of 4" PVC

and a 4" elbow connected to the slotted pipe nipple.

See Figure 3.3 for required positioning of elbow. This

piping configuration will promote smooth uniform flow.

The piping from the pump to the elbow should be

sized based on the pump discharge. Use bushings/

reducers as necessary to connect to the elbow.

3.5) Maximum flow through the splitter system is dependent

on the number of trench pipe openings.

The splitter

system can handle 30 gpm with 5 openings, 21

gpm with 4 openings, 17 gpm with 3 openings

and 13 gpm with 2 openings.

Note: Assure slot in pipe nipple is centered and facing upward

when connecting coupling or PVC.

Note: Basin must be leveled at this time in both

directions.

Note: The splitter system must sit level on undisturbed ground

or on packed sand or gravel before backfilling.

SK1941

Figure 2.2

Figure 2.4

SK1942

Figure 1.2

SK1956

SK1944

Figure 3.2

SK1943

Figure 3.1

SK2100

Figure 3.3

Patent No. 6,112,766

and 6,152,650

INLET HOLE

(DO NOT USE FOR OUTLET)

POSSIBLE CUTOUTS

MOLDED IN HOLES

SK1939

Figure 1.1

BOTTOM OF

V-GROOVE

BASIN WALL

MOLDED

DIAMETER

SK1973

MATING

SURFACE

SK1940

PIPE

DIRECTION

OUTSIDE OF

BASIN WALL

PIPE SEAL

DO NOT OVER

TRIM KNOCK-OUTS

BUCKLE SEAL TO INSERT.

3/4"

SLOTTED

PIPE NIPPLE

SLOT

SLOTTED

PIPE NIPPLE

OUTLET PIPES

1 1/2

SEPTIC TANK

OUTLET PIPE

COUPLING, RUBBER

(SHOWN) OR PVC

(SUPPLIED BY OTHERS)

DO NOT TIGHTEN

FOR THIS STEP

NUMBER OF TRENCH

PIPES VARIES FOR

EACH INSTALLATION.

4" PVC PIPE

MINIMUM 3' LENGTH

COUPLING, RUBBER

(SHOWN) OR PVC

(SUPPLIED BY OTHERS)

DO NOT TIGHTEN

FOR THIS STEP

NUMBER OF TRENCH

PIPES VARIES FOR

EACH INSTALLATION.

4" PVC ELBOW

ORIENTATION AS

SHOWN.

PUMPED EFFLUENT