Carbolite EZS Series User Manual

Page 4

E range

4

MF65-1.01

MF65-1.00

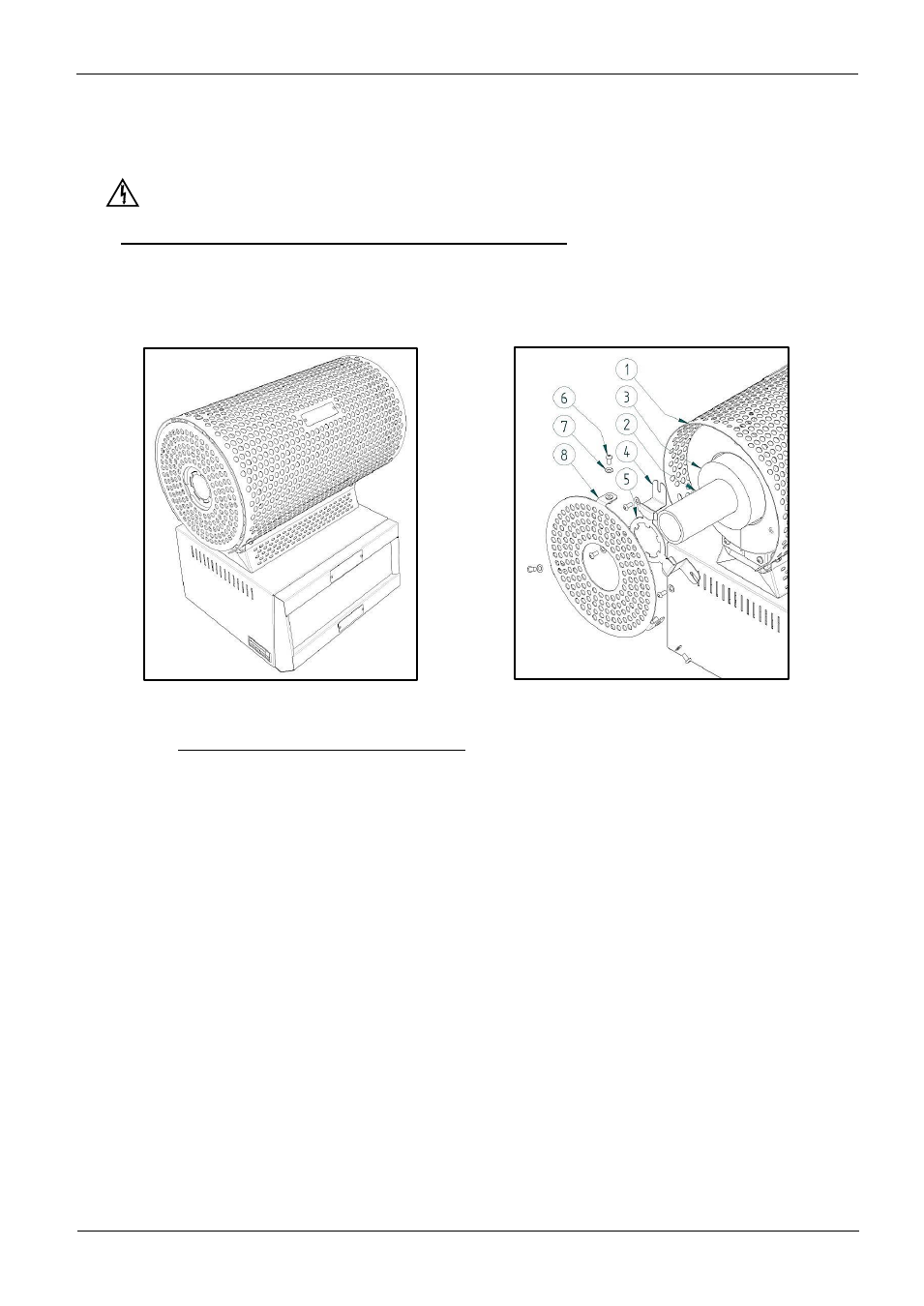

2.3 Setting up – horizontal models

The EHA and EHC horizontal models must have work tubes fitted before being used. The

diameter of the work tube is a customer order option and therefore varies between tube

furnaces.

Note : If a metal work tube is being used in the furnace, ensure that it is earthed. See the

safety warning in Section 3.5, page 18.

Fitting the standard work tube in an EHA/EHC furnace. (Tools required: 4mm Hex key.)

The fitting of the work tube is as follows with reference to Figure 2-2. Please note that

standard work tubes are also referred to as tubes suitable for working in air. They are 150mm

longer than the heated length of the furnace (see Table 9-1 page 24). Read section 5.2 before

fitting the work tube.

Remove the work tube end guard (item 8) then remove the work tube adaptor fixing bracket

(4) that holds in place the work tube end stop (5) and the work tube adaptor (3) from one

side only. Note that if a different work tube with a different outer diameter is being fitted it

will be necessary to fit new correctly sized work tube adaptors (3) in which case both end

guards and work tube adaptor fixing brackets (4) will need removing.

Slide the work tube into the furnace through the work tube adaptor (3) until it reaches the

opposite work tube end stop (5). Note that the work tube might be a tight fit when it is new

and may need to be twisted backwards and forwards slightly as it slides in. For long work

tubes it may be necessary to use a long wooden pole such as a broom handle to support

and line up the work tube as it is pushed through. It may also take 2 people to perform this

operation.

Reassemble the work tube end stop (5), work tube adaptor bracket (4) and tube end guard

(8).

Figure 2-1. EHA model mounted on a control box.

Figure 2-2. Exploded view showing how to fit

the work tube in the EHA

Index to numbered items in Figure 2-2

1. EHA/EHC tube furnace

2. Work tube (diameter customer option)

3. Work tube adaptor (size dependent on work tube diameter)

4. Work tube adaptor fixing bracket

5. Work tube end stop (size dependent on work tube diameter)

6. Fixing screws M6 x15

7. Washer M6

8. Tube furnace end guard

1-