On 3.5, pa, On 3.5 – Carbolite EZS Series User Manual

Page 18

E range

18

MF65-1.01

MF65-1.00

It is possible to use local trim in the end zone controllers to enter a positive or negative adjustment

from the centre zone temperature. Once entered this trim will always be added or subtracted from

the retransmitted set temperature. In level 2 of the end zone controller (see controller operating

instruction), scroll to

LOC.T

(local trim) and use the Up Down enter the desired positive or

negative difference to be added to the end zone set temperature. There is no need to alter the centre

controller.

C.

Independent Control

In this case the three controllers are completely independent. Remember that it is not possible to

maintain very different zone temperatures because of heat transfer within the furnace body and

work tube.

3.4 General Operating Advice

Heating element life is shortened by use at temperatures close to maximum. Do not leave the

furnace at high temperature when not required. The maximum temperature is shown on the rating

label and in section 9.1 page 24 of this manual.

Light weight ceramic fibre insulation can easily be marked by accidental contact. Some fine

cracks may be visible on the surface of the insulation, or may develop in the surface of the

chamber due to the progressive shrinkage of the insulation materials. Cracks are not usually

detrimental to the functioning or the safety of the furnace.

3.5 Operator Safety

The ceramic materials used in furnace manufacture become electrically conductive to some extent

at high temperatures. Also, there are partially exposed heating coils in the chamber. DO NOT use

any conductive tools within the work tube without isolating it. If a metal work tube is used, it must

be earthed (grounded).

Switch off the Heater switch whenever loading or unloading the furnace. The elements are

isolated when the Heater switch is OFF (see Figure 1-1, page 3). This switch cuts both sides of the

circuit via a contactor

3.6 Work tube Life

A ceramic work tube may be cracked if work pieces are

inserted too quickly or at temperatures below 900°C when

the work tube is more brittle. Large pieces should also be

heated slowly to ensure that large temperature differences do

not arise.

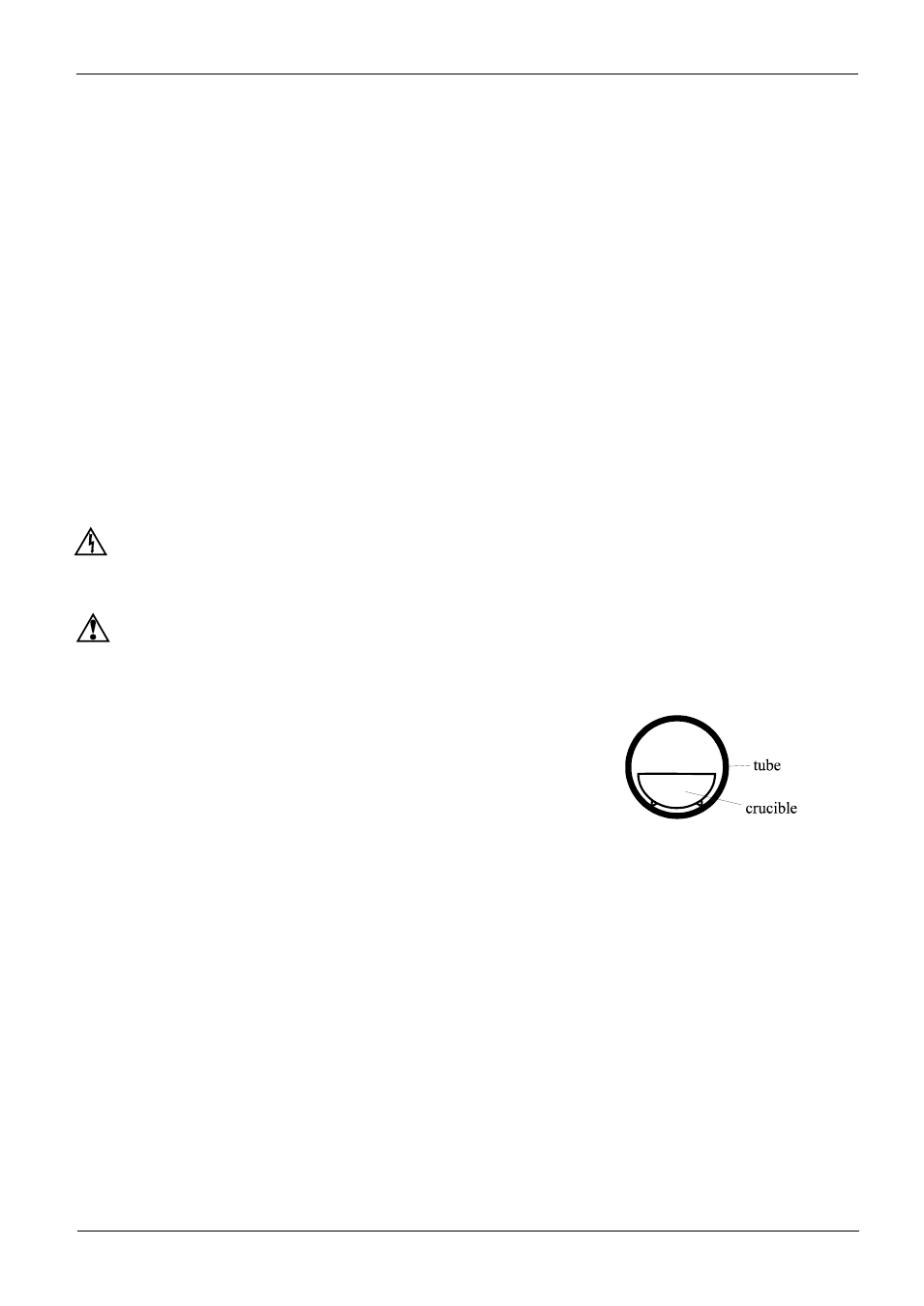

Poor thermal contact should be encouraged between the work

piece and the work tube; crucibles or boats should be of low

thermal mass and should have feet to reduce the contact with

the work tube (Figure 3-2).

Do not set too high a heating rate. Large diameter work tubes are more susceptible to thermal

shock than smaller diameters. Work tubes that extend beyond the heated part of the furnace are

more at risk. A general rule for maximum heating rate is 400/internal diameter (°C/min); for

75mm i/d work tubes this comes to 5°C per minute. The controller can be set to limit the heating

rate.

3.7 Pressure

Work tubes are not able to accept high internal pressure. When gas seals or similar fittings are in

use, the gas pressure should be restricted to a maximum of 0.2 bar (3 psi). A pressure of about half

of that should normally be sufficient to achieve the desired flow rate. The customer must ensure

that the exhaust path from the work tube is not blocked, so that excess pressure does not occur.

3.8 Gas Tightness

IAP material work tubes are impervious; sillimanite may look similar but is porous. Ensure that

the correct work tube material is used before connecting and using any gases other than inert gases

such as nitrogen.

Figure 3-2. Diagram Showing Poor Thermal

contact of Work piece to Avoid Work tube

Cracking