Carbolite GVC Series User Manual

Page 4

G range

4

MF48 -1.18

Work Tubes and Fittings

Tubes of various diameters and lengths

may be fitted.

Type C: minimum length for the furnace

Type D: 300mm longer than C, to allow

for the fitting of end seals.

A pair of removable “tube adaptors” (or

“end adaptors”) form part of the end

insulation. These may be blank (no hole) or may have a hole to suit a work tube, depending on the

customer order. Additional adaptors may be ordered to suit different work tube sizes. Check that

the end adaptors are correct for the tube: if not, seek advice from Carbolite. Small alterations to the

hole in the adaptors may be made with a file, but first read the section on ceramic fibre safety

(5.2).

To insert a work tube it is often convenient to use a long pole (such as a broom handle) to guide it

into the far end of the furnace.

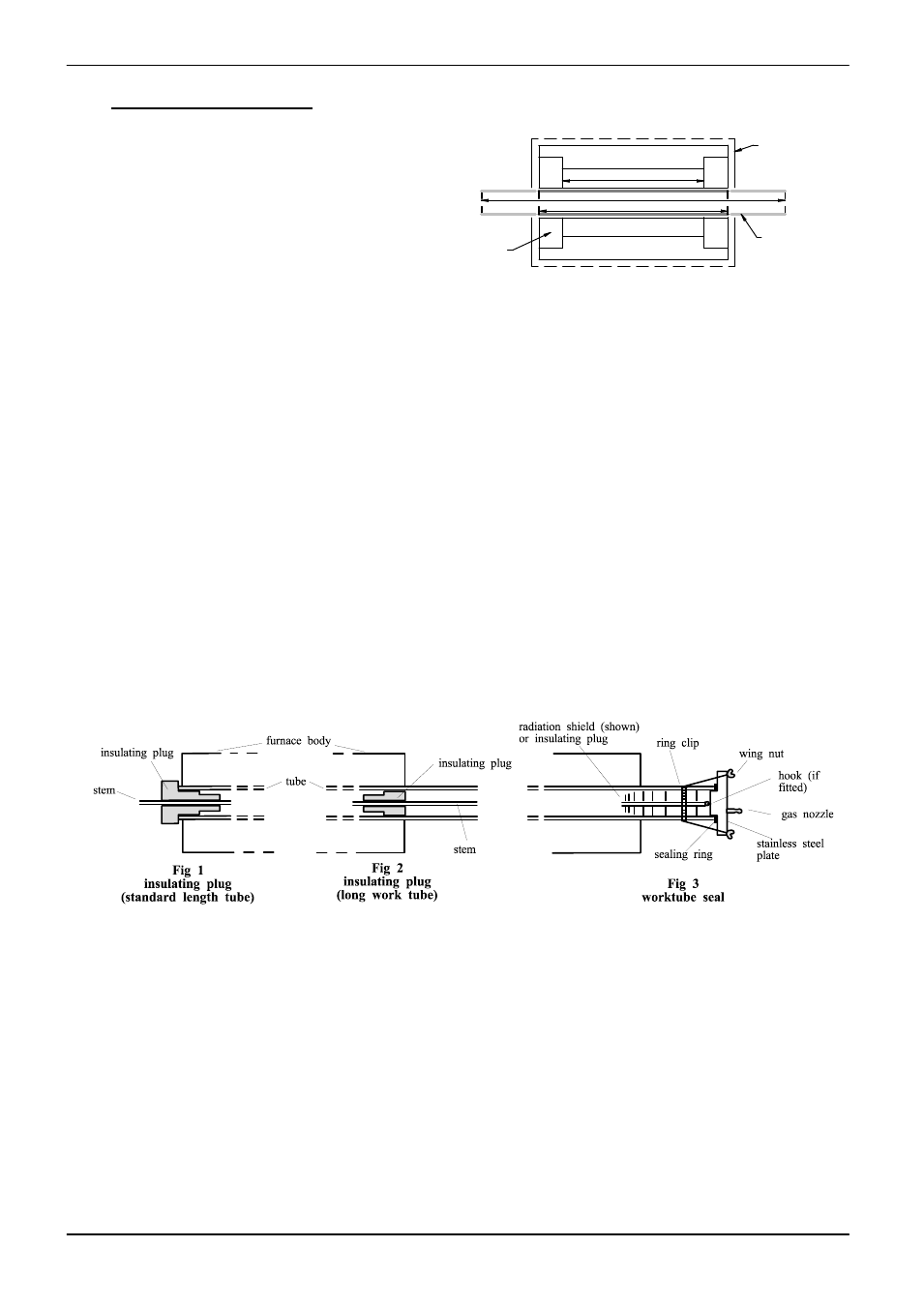

For optimum temperature uniformity, insulating plugs should be placed in the tube ends as shown

in fig.1. With an extended work tube (type D), the stem of the plug assembly should line up with

the end of the tube as in fig.2. Alignment of radiation shields is similar to that of plugs.

If stainless steel seals with gas inlets are supplied they are to be fitted as shown in fig.3; the stem

of any insulating plug should touch the seal. For vertical use a hook and eye arrangement holds the

upper insulating plug assembly (in some cases a gland nut may alternatively be used).

Horizontal use: if heavy fittings are to be clamped to the end of an extended work tube they can

increase the bending stress at the centre of the tube. Support such fittings in such a way that

expansion of the tube is allowed. A horizontal tube support kit can be supplied for this purpose (in

the versatile models the kit includes supports).

If a metal work tube is being used in the furnace, ensure that it is earthed. See the safety warning in

section 3.4.

Heated Length

Type C

Type D

End Adaptor

Work Tube

Guards