Carbolite VMF Series User Manual

Page 9

AAF, GSM, VMF

MF06 3.32

9

5.5 Thermocouple Replacement

Disconnect the furnace from the supply, and remove the furnace back panel.

Make a note of the thermocouple connections. The negative leg of the thermocouple is marked

blue. Compensating cable colour codings are:

Negative

positive (type K)

White

green

Disconnect the thermocouple from its terminal block.

Bend the metal tag, or release the screw, to release the thermocouple sheath, withdraw the sheath,

and shake out any fragments of thermocouple.

Re-assemble with a new thermocouple observing the colour coding, ensuring that the

thermocouple is not twisted as it is being inserted and that the metal tag is bent back, or the screw

inserted, to grip the sheath.

5.6 Element Replacement (AAF 11/3, AAF 12/3, AAF 11/7, AAF 12/7, GSM)

See section 5.2 - wearing a face mask is recommended.

The chamber of this type of furnace is formed by winding resistance heating wire on to a

refractory muffle former. In the event of failure, the whole "wound muffle" assembly must be

replaced.

Disconnect the furnace from the supply and remove the furnace back panel. GSM: Pull the

chimney out of the top of the furnace.

Make a note of the wiring connections; see the section above which refers to the thermocouple

colour coding.

Unfasten the electrical connections to the inner chamber (brick-box) and remove the thermocouple

and sheath (see thermocouple replacement instructions). If the connections are secured by

hexagonal nuts, two spanners should be used to avoid cracking the porcelain mounting.

Undo any self-tapping screws and hook bolts necessary to release the brick-box.

Support the front of the brick-box as you withdraw it from the case so it does not fall onto the

electrical connections below.

Remove the brick-box lid and top insulating board, noting how it is assembled and observing the

position of the heating element wires (or “tails”).

Pull the element tails out of the terminal block and remove sufficient insulation to allow access to

the heating element. Check and replace damaged insulation.

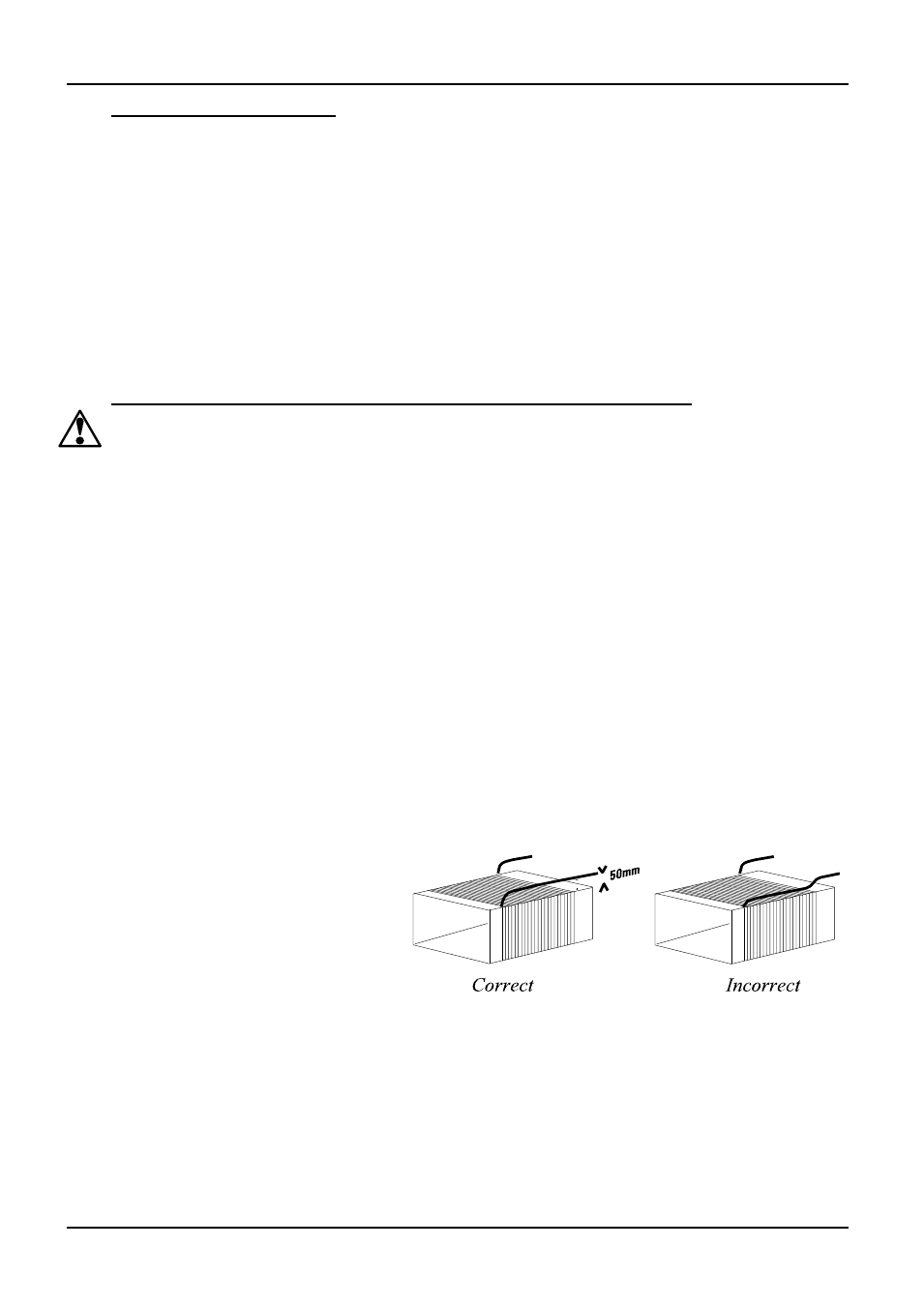

Fit the new heating element,

ensuring that the tails are separated

from the element by at least 25 mm

(preferably 50mm) of insulation –

see the picture.

Feed the element tails through the

terminal blocks and tighten the

clamping screws using two spanners

as before. Cut off excess element tails.

Complete the fitting of the insulation and refit the lid. Do not use any cement unless supplied by

Carbolite, as other types may chemically attack the heating element.

Replace and fasten the brick-box into the furnace case.

Replace the thermocouple and sheath and remake the electrical connections. In porcelain and brass

terminal blocks the brass connector should be slightly loose in its porcelain support block to allow

for expansion.

Replace the back panel and reconnect the electrical supply.