Specifications, Carbolite engineering services – Carbolite VMF Series User Manual

Page 16

Carbolite, Parsons Lane, Hope,

Hope Valley, S33 6RB, England.

Telephone: +44 (0)1433 620011

Fax: +44 (0)1433 621198

E-mail: [email protected]

The products covered in this manual are only a small part of the wide range of

ovens, chamber furnaces and tube furnaces manufactured by Carbolite for

laboratory and industrial use. For further details of our standard or custom built

products please contact us at the address below, or ask your nearest stockist.

Copyright © 2014 Carbolite Limited

For preventive maintenance, repair and calibration of all Furnace

and Oven products, please contact:

Carbolite Engineering Services

Telephone: +44 (0)1433 624242

Fax: +44 (0)1433 624243

Email: [email protected]

MF06 – 3.32

14/08/14

9.0 S

PECIFICATIONS

Carbolite reserves the right to change specifications without notice

.

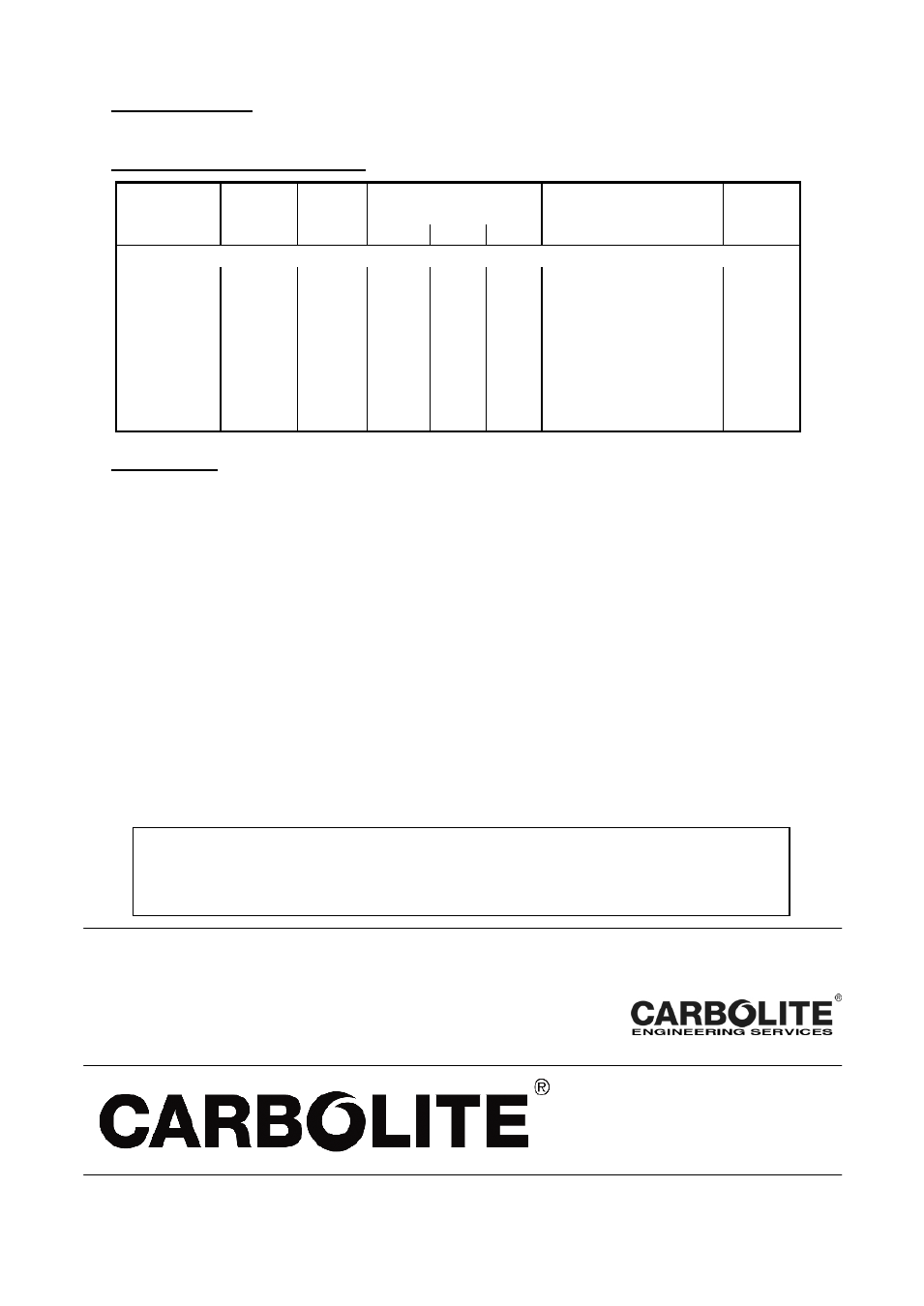

9.1 Models Covered by this Manual

MODEL

Max.

Temp.

Max.

Power

Chamber Size (mm)

Heating Elements

Net

Weight

(°C)

(kW)

H

W

D

(l)

(kg)

Ashing, Burn-off and Coal & Coke Testing Furnaces

AAF 11/3

1100°C

2.1

85

150

250

Wound muffle

22

AAF 11/7

1100°C

3.9

90

170

445

Wound muffle

63

AAF 11/18

1100°C

7

235

196

400

Concealed wire

70

AAF 12/3

1200°C

2

85

150

250

Wound Muffle

22

AAF 12/7

1200°C

6

90

170

445

Wound Muffle

63

AAF 12/18

1200°C

7

235

196

400

Concealed wire

70

GSM 11/8

1100°C

3.0

125

185

345

Wound silica muffle

63

VMF 10/6

1000°C

3.0

100

210

260

Vacuum formed slabs

45

9.2 Environment

The furnaces contain electrical parts and should be stored and used in indoor conditions as

follows:

temperature:

5°C - 40°C

relative humidity:

maximum 80% up to 31°C decreasing linearly to 50% at 40°C