Caution, Setup instructions – BASELINE 225 User Manual

Page 6

2 •

Important: Always read and follow instructions.

Setup Instructions

Receiving

The shipment should be thoroughly inspected as soon

as it is received. The signed bill of lading is acknowl-

edgement, for the carrier, of receipt in good condition

of the shipment covered by our invoice.

If any of the goods called for on this bill of lading are

shorted or damaged, do not accept them until the car-

rier makes a notation of the shorted or damaged goods

on the freight bill. Do this for your own protection.

NOTIFY THE CARRIER AT ONCE if any hidden loss or

damage is discovered after receipt and request him to

make an inspection. If the carrier will not do so, prepare

an affidavit to the effect that you have so notified the

carrier (on a certain date) and that he has failed to com-

ply with your request.

IT IS DIFFICULT TO COLLECT FOR LOSS OR DAM-

AGE AFTER YOU HAVE GIVEN THE CARRIER A CLEAR

RECEIPT.

File your claim with the carrier promptly. Support

your claim with copies of the bill of lading, freight bill,

invoice, and photographs, if possible.

Unpacking the Unit

• Remove the shipping carton from the pallet.

• Remove all loose parts and accessories packed

around the unit.

Remove Balancer from Pallet

1.

Remove the shipping bolts that hold the balancer

to the pallet.

CAUTION

Do not use the control panel, control panel

base, accessory storage, faceplate, hood or

shaft to lift the balancer.

CAUTION

Use help to remove the balancer from the

pallet. The unit is heavy and the weight is

not evenly distributed. Dropping the unit

may cause personal injury or equipment

damage.

2.

Lift the balancer off the pallet and place it in its

operating location.

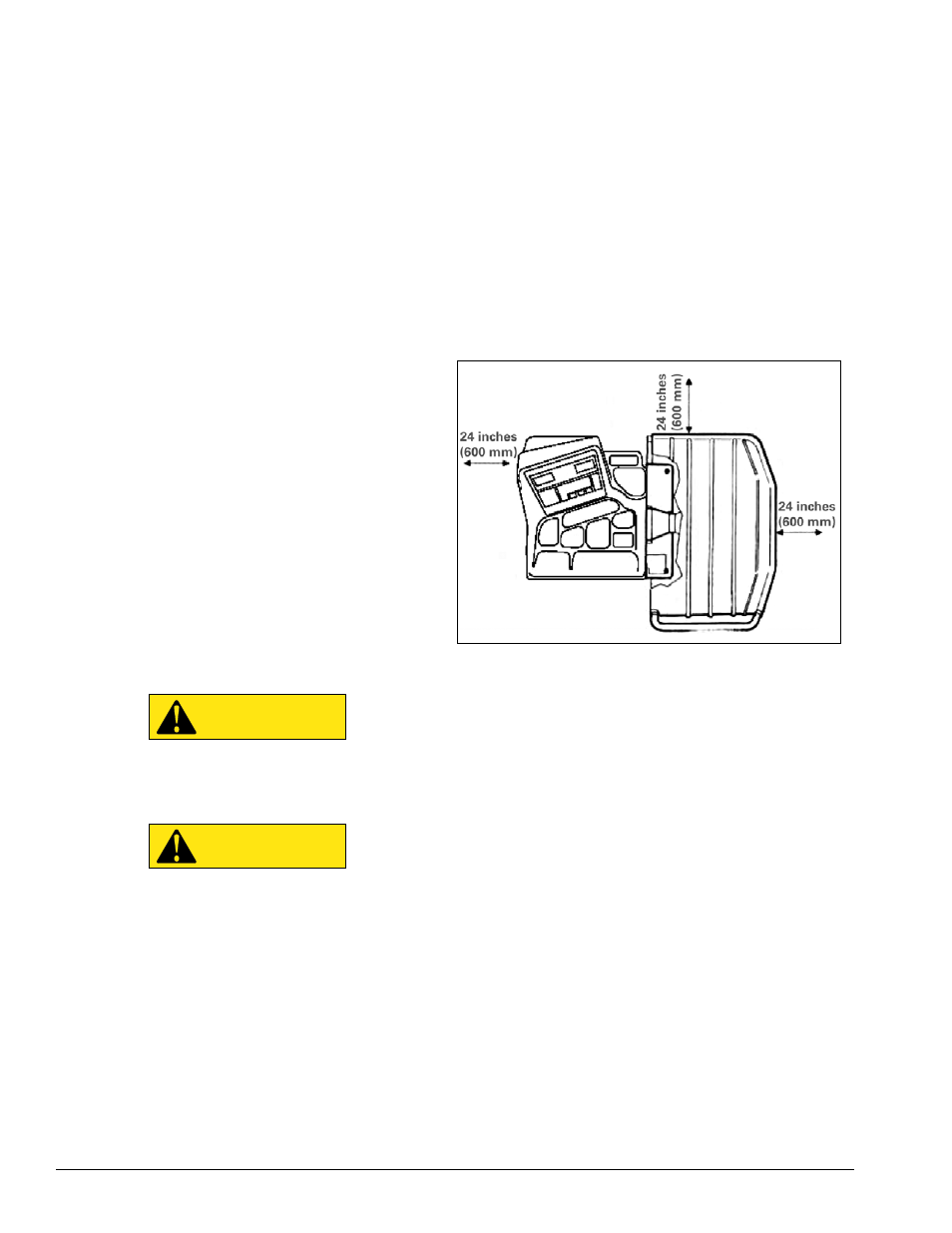

Floor and Space Requirements

The balancer must be located on a flat floor of solid

construction, preferably concrete. The balancer must

sit solidly on its three feet. If the balancer is not level,

does not sit solidly on its three feet, or is placed on an

unstable floor, the balancer will not function properly

and may produce inaccurate balance readings.

Do not operate the balancer while it is on the pallet.

Select a location for the balancer that provides a level,

solid floor, and adequate clearance around and above

the balancer. Make sure the location selected has

enough room above and behind the unit so the hood

can be raised completely. The location must also pro-

vide working room for mounting and removing wheels.

Make sure the area has adequate lighting.

Figure 1 - Space Requirements

Electrical Requirements

See serial tag for the appropriate power requirements

of your machine.

Always have a qualified electrician install the proper

receptacles in accordance with state and local codes.