Troubleshooting – BASELINE 225 User Manual

Page 22

18 •

Important: Always read and follow instructions.

Troubleshooting

Listed below are faults that the user can remedy if

the cause is found to be among those indicated. Any

other defect or malfunction will require the attention of

a qualified technician: Contact your nearest BaseLine™

service center.

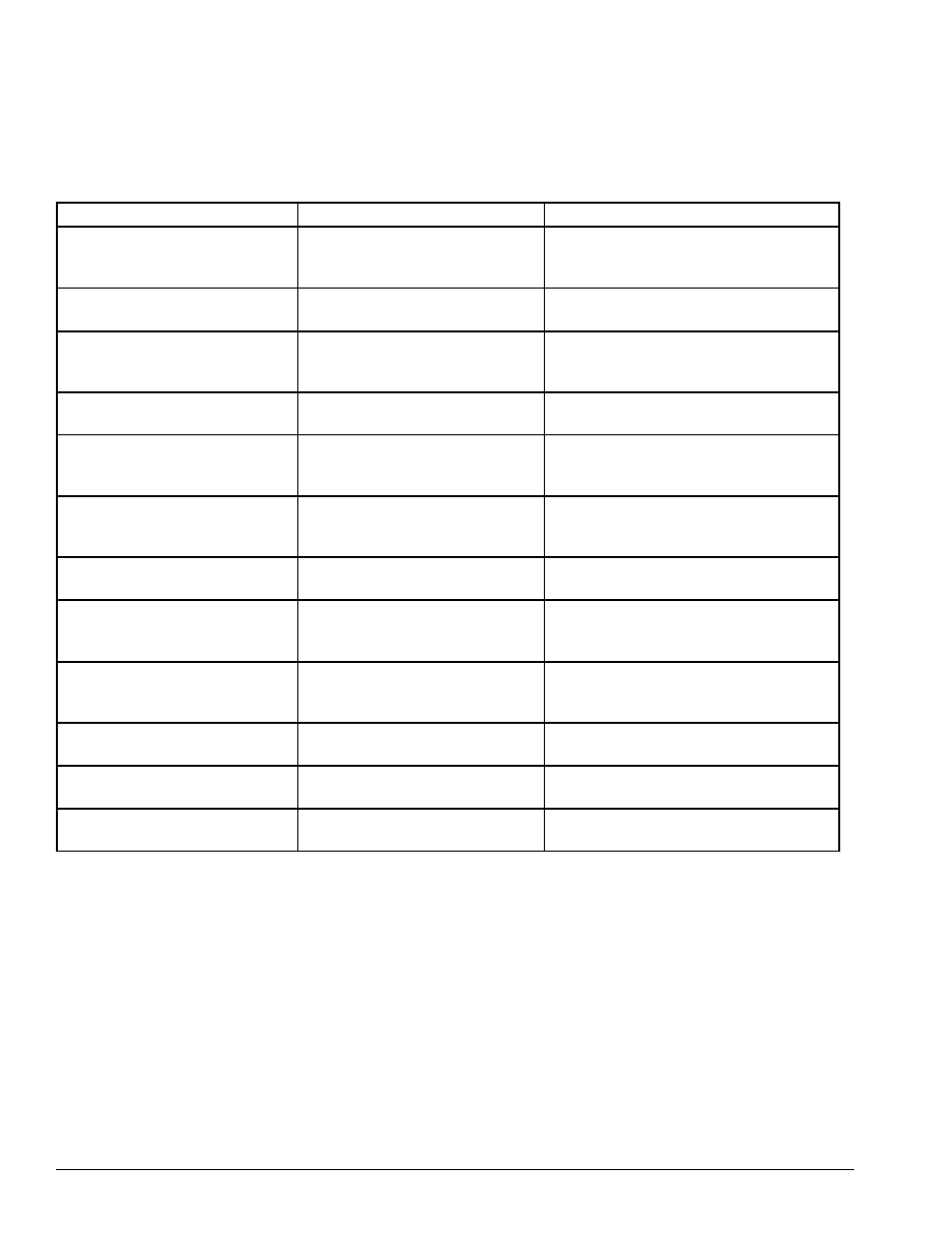

ERROR

CAUSE

REMEDY

Machine fails to switch on,

with no light showing at the

main switch.

No power at the socket.

➤

Test the main voltage.

➤

Check the electrical power circuit

installed in the workshop.

Defective main plug.

➤

Check the integrity and efficiency of

the plug, and replace if necessary.

Machine fails to switch on,

even with the light showing at

the main switch.

One of the fuses F1, F2, F3 at

the circuit board has blown.

➤

Replace the blown fuse.

Wheel fails to spin when

START button is pressed.

The wheel guard is raised.

➤

Lower the guard.

Machine gives discontinuous

unbalance values.

The machine has been jolted or

destabilized during the spin.

➤

Repeat the spin, taking care not to

disturb the machine while data acqui-

sition is in progress.

The machine is not sitting level

on the floor or is on an unstable

floor.

➤

Verify the stands and adjust the feet,

utilizing shims if necessary.

The wheel is not properly

clamped.

➤

Tighten the hubnut so that the wheel

is firmly restrained.

Several spins are needed to

balance a wheel.

The machine has been jolted or

destabilized during the spin.

➤

Repeat the spin, taking care not to

disturb the machine while data acqui-

sition is in progress.

The machine is not sitting level

on the floor or is on an unstable

floor.

➤

Verify the stance and adjust the feet,

utilizing shims if necessary.

The wheel is not properly

clamped.

➤

Tighten the hubnut so that the wheel

is firmly restrained.

The wheel dimensions entered

are incorrect.

➤

Verify the dimensions and program

correctly.

The machine is not properly

calibrated.

➤

Run the calibration procedure.