BASELINE 225 User Manual

Page 15

Important: Always read and follow instructions.

• 11

Wheel Data Entry (W, D, A)

1.

Press

. The machine is ready to receive the

WIDTH (W) measurement (the corresponding LED will

light).

2.

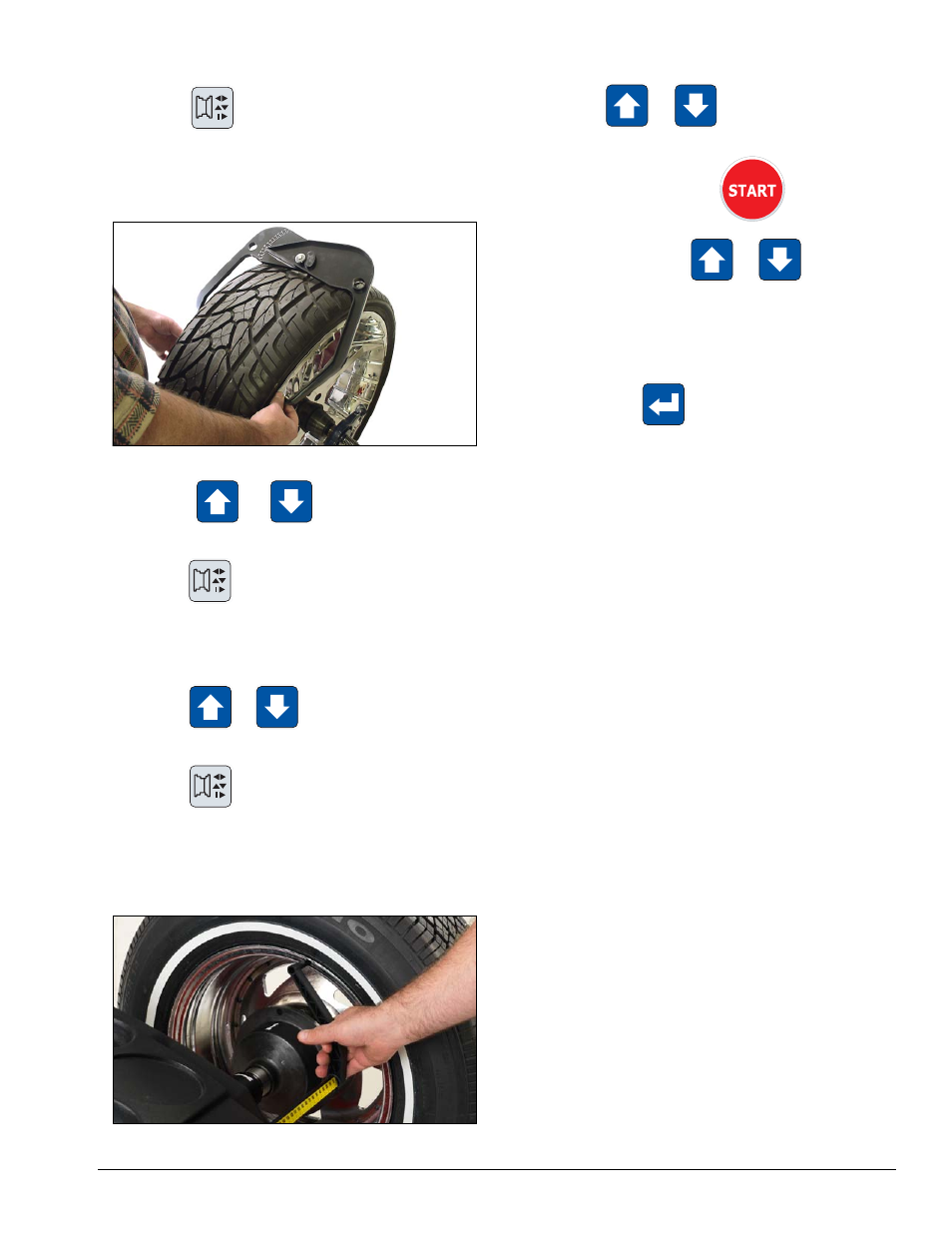

Measure rim width using the caliper provided with

the balancer (figure 12).

Figure 12 - Caliper Placement On Wheel

3.

Press

or

until the correct WIDTH

number is set in the right display window.

4.

Press

to confirm the W input and set up the

machine to receive the DIAMETER (D) measurement

(the corresponding LED will light).

5.

Read the diameter that is printed on the tire.

6.

Press

or

until the correct DIAMETER

number is set in the right display window.

7.

Press

to confirm the D input and set up the

machine to receive the OFFSET (A) measurement (the

corresponding LED will light).

8.

Move the offset arm until it touches the edge of

the inside rim flange as shown figure 13 according to

the different terminal available on the gauge.

Figure 13 - Offset Arm at Clip-on Weight Location

9.

Read the machine/rim distance on the gauge.

10.

Press

or

until the correct OFFSET

number is set in the right display window.

11.

Lower hood and press

to spin wheel.

Note: If you hold down

or

the numbers

will spool up or down quickly making data input all the

more rapid.

Note: DIM inputs can be converted between inches

and millimeters.

To do this press

to toggle between an inch or

millimeter measurement display. A LED on the panel

will light to identify the current unit of measurement

(mm or inch).

Note: When in static mode, you only need to input the

DIAMETER wheel measurement.