Barranca Diamond PF10 Power Feed Trim Saw User Manual

Page 19

19

CUTTING LUBRICANT REPLACEMENT

The PF10 Trim Saw requires periodic routine maintenance to remove the build up of rock mud (sludge) and

dirty lubricating fluid from the reservoir. It will be apparent to the user that the lubricating fluid is dirty and

needs to be changed if the oil residue on the saw table after cutting is thick and dark with rock sludge build up.

The oil liquid can be removed rapidly using the drain pipe attached to the bottom drain hole at the base of the

oil reservoir (fig 24).

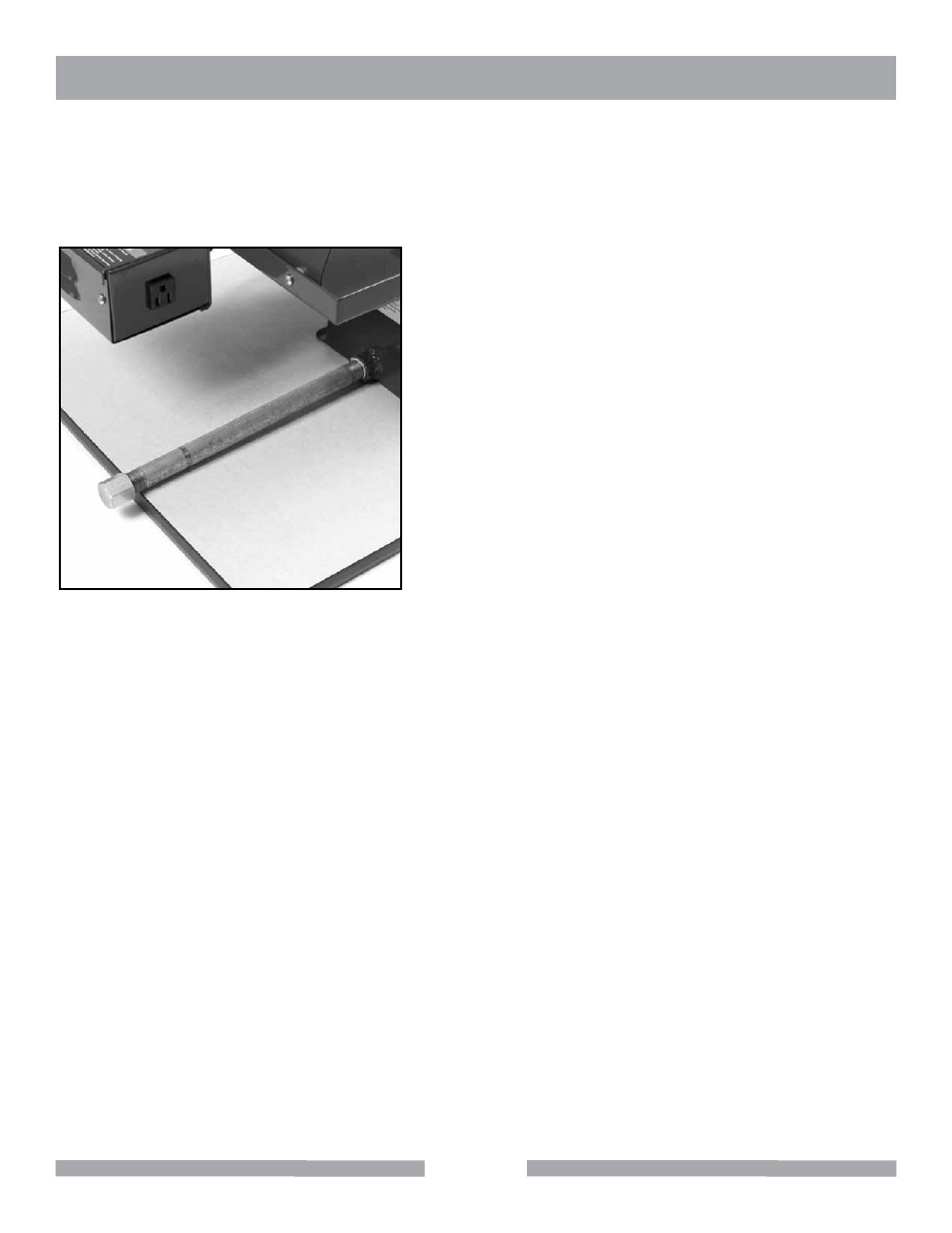

Fig 24. Drain pipe

A five gallon bucket or collection container can be placed under the outlet cap of the pipe and the cap removed

with an adjustable wrench to let the free oil flow into the bucket for proper disposal. It may be necessary to

hold the pipe with gripping pliers to prevent it from unthreading from the reservoir when removing the cap. The

sludge residue will likely not flow through the drain pipe and will remain inside the oil reservoir. Therefore, the

sludge should be removed when the slab saw oil lubricant is drained by removing the belt guard, saw table and

blade, and extracting the sludge with a spatula or spoon. Once the sludge is removed, wipe clean the inside

of the tank with a disposable towel and refill the cutting lubricant to cover the bottom 1/4" of the blade (fig 4).

Dispose of the used oil and sludge properly. Be sure to check the fluid level of the cutting lubricant inside of the

oil reservoir after every 3 to 5 hours of use as the fluid will be absorbed onto the rock material, combine with

rock mud (sludge) and be lost due to heat and evaporation.

PF10

MAINTENANCE