Troubleshooting 6 – Echo 76824 Owners Manual v.1 User Manual

Page 27

PN 18280-00 R121505

25

Section

Before performing any of the corrections in this troubleshooting chart, refer to the appropriate information contained in this manual

for the correct safety precautions and operating or maintenance procedures. Contact your nearest dealer or the factory for service

problems with the machine.

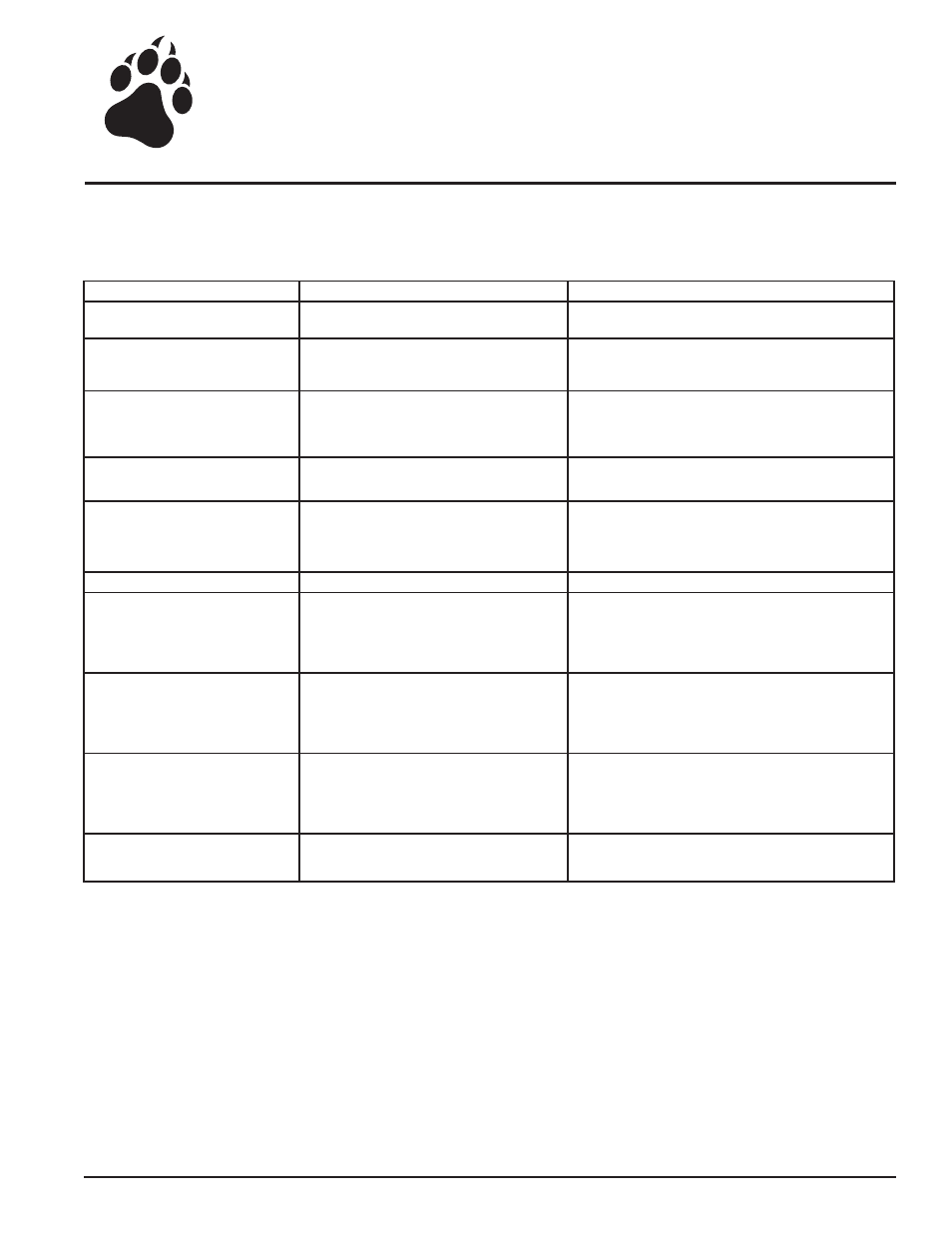

PROBLEM

POSSIBLE CAUSE

REMEDY

Rotor does not turn.

Obstructed discharge

Plugged rotor.

1.

2.

Use branch or similar object to clear discharge.

Clear rotor.

1.

2.

Hard to feed chipper or excessive power

needed to chip

Obstructed discharge.

Dull chipper blades.

Improper blade clearance.

1.

2.

3.

Use branch or similar object to clear discharge.

Sharpen blades

Adjust clearance.

1.

2.

3.

Chipper requires excessive power or

stalls

Obstructed discharge.

Plugged rotor.

Green material will not discharge.

1.

2.

3.

Use branch or similar object to clear discharge.

Clear rotor, feed material into shredder more evenly.

Alternately feed dry material or allow material to dry.

1.

2.

3.

Drive belts squealing or smoking.

Plugged rotor.

Loose or worn belts.

1.

2.

Clear rotor.

Adjust belt tension or replace belts if needed.

1.

2.

Vibration while running.

Drivehead vibration

Rotor out of balance.

1.

2.

Check drive belts and pulleys for bad or worn spots.

Inspect rotor for broken or missing chipper blades and

paddles. Repair if needed. Check rotor to see if it wobbles.

Check to see if the rotor is assembled correctly.

1.

2.

Engine dies or runs poorly.

Engine problems

1.

Contact your local engine dealer.

1.

Will not attain normal feed rate.

Engine not operating at correct speed.

Control linkage damaged or binding.

Bypass valve stuck partially open (problem in

one direction only).

1.

2.

3.

Repair engine governor.

Repair control linkage.

Repair bypass valve. Remove foreign material from

valve.

1.

2.

3.

Will not feed when control arm is

moved.

Control linkage damaged or not connected.

Drive between engine and pump damaged.

Pump low on fluid.

1.

2.

3.

Repair or reconnect control linkage.

Repair drive (replace broken belt, repair sheared key, repair

splined coupling, etc.)

Refill reservoir. Purge air from system.

1.

2.

3.

Feed rate is sluggish under load.

Loose belt between engine and pump.

Pump low on fluid.

Large amount of water in hydraulic fluid (evapo-

rates when hot, resulting in low fluid level).

1.

2.

3.

Adjust tension on drive belt (replace is necessary).

Refill reservoir. Purge air from system.

Drain fluid from reservoir and unit, replace filter element,

and refill with new fluid.

1.

2.

3.

Hydraulic feed will not pull in logs over

4" in diameter, or continuously stalls or

stops.

Hydraulic system overloading and causing

system to go over relief.

1.

Check relief pressure in system with a pressure gauge

rated to 2500 psi (system set by factory at 1750 psi).

1.

Troubleshooting

6